Free-form surface non-contact dimensionality-reducing error-separating detection method and device

A technology of error separation and detection method, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the limitation of free-form surface contour measurement accuracy, insufficient measurement accuracy, and inability to overcome characteristic differences such as sample surface roughness, undulations, and inclination angles, etc. problem, to achieve the effect of nanoscale feed resolution and positioning, improve the measurement range, and improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

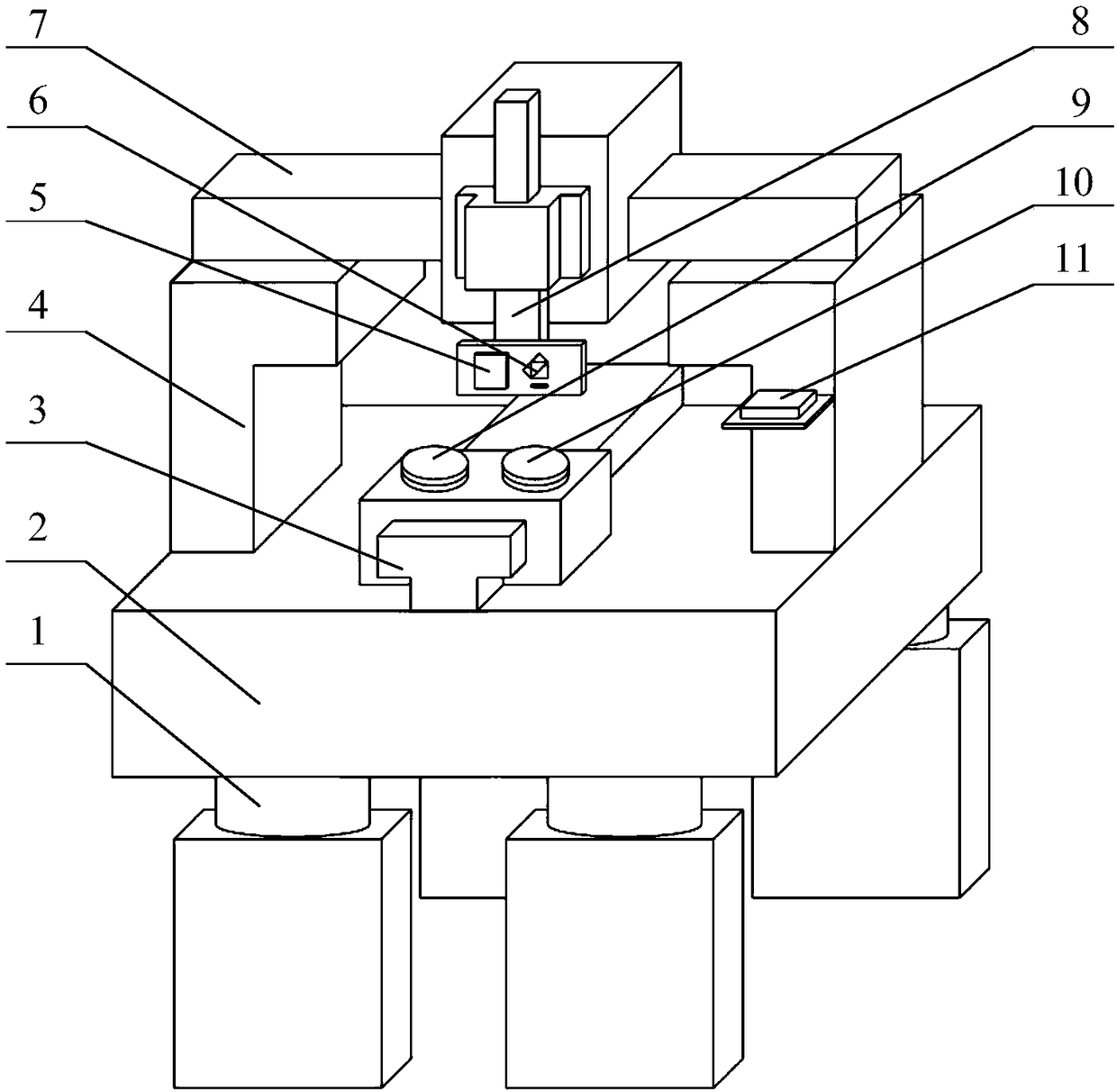

[0032] Such as figure 1 As shown, the device of the present invention includes: active air bearing vibration isolation spring, air bearing vibration isolation base, X direction air bearing guide rail, gantry frame, spectral confocal distance measurement sensor, laser interference displacement measurement mirror group, Y direction air bearing Guide rail, Z-direction air bearing guide rail, free-form surface sample attitude adjustment device, reference flat crystal attitude adjustment device, laser interferometer;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com