Open-loop CONTROL unit or closed-loop control unit for A MOULDING MACHINE

A technology of open-loop control and closed-loop control, applied in general control systems, adaptive control, control/regulation systems, etc., can solve problems such as non-optimized and too slow trajectories, and achieve the effect of optimized trajectories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

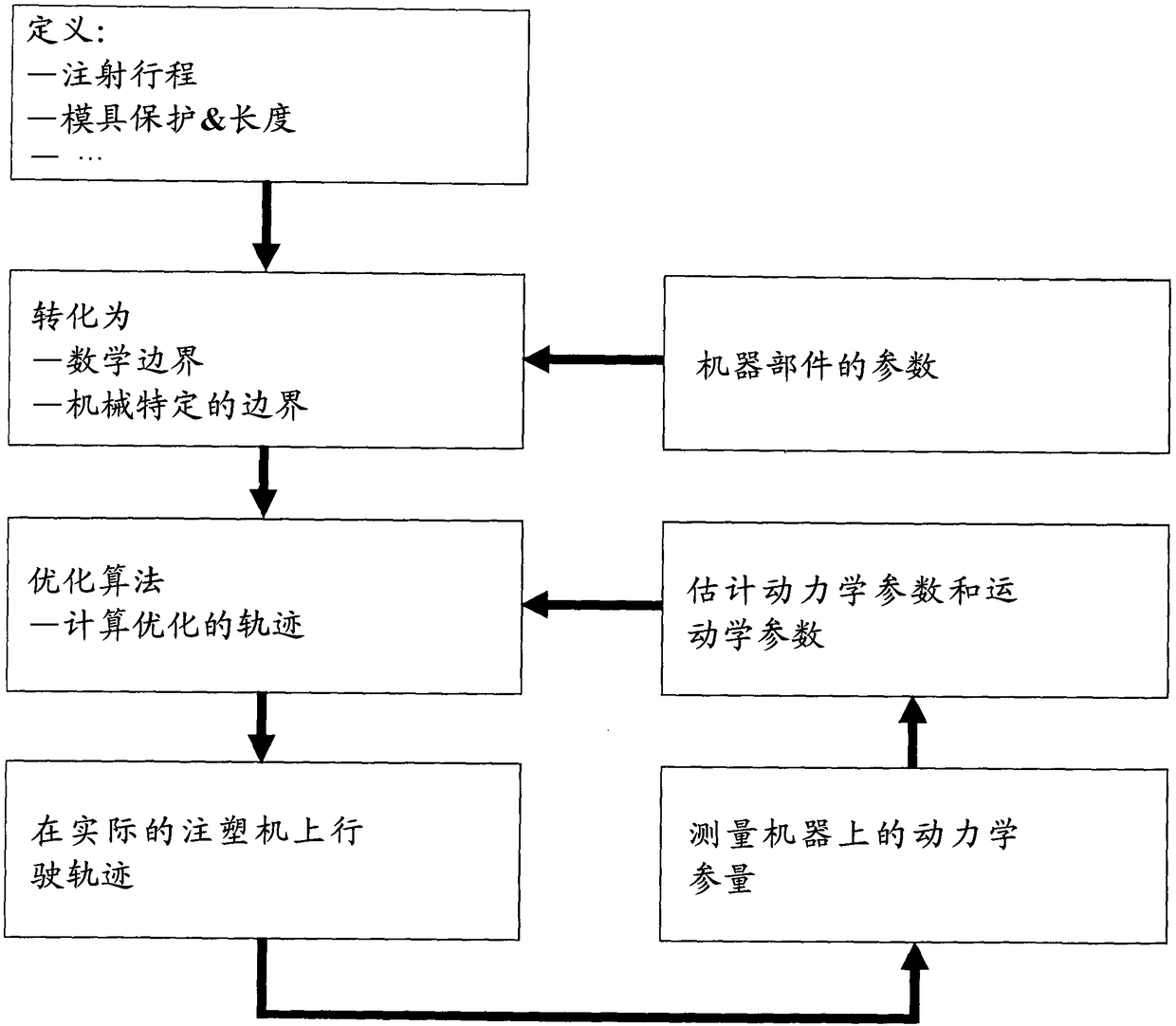

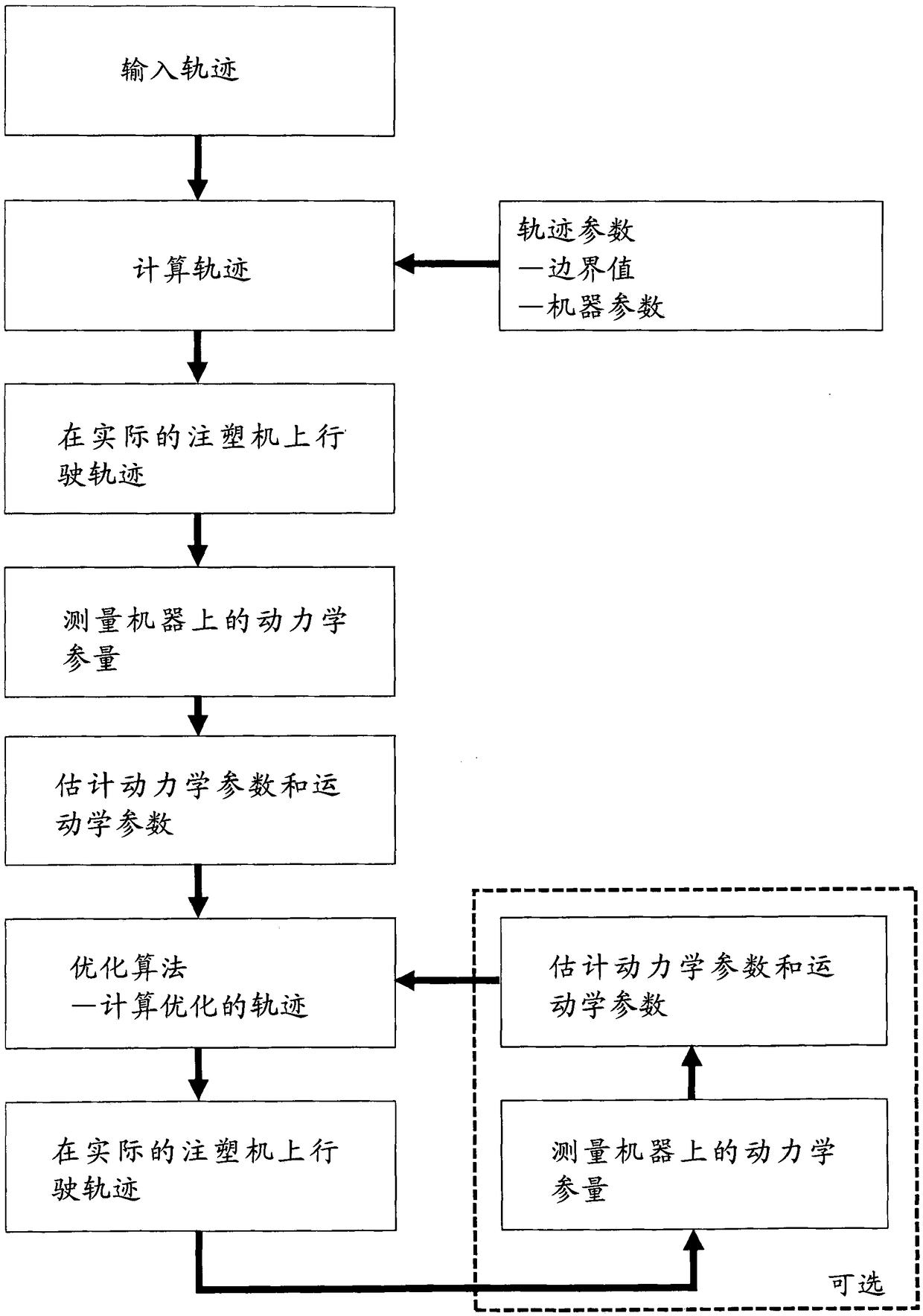

[0044] The molding machine 1 is given in the form of an electric crank lever machine, which not only performs a mold clamping movement with the aid of a crank lever, but also generates a clamping force (through a suitable transmission ratio of the crank lever). The mold clamping movement and the generation of the mold clamping force should be performed optimally based on different criteria and taking into account certain boundary conditions.

[0045] Here, the possible boundary conditions are:

[0046] -The desired mold stroke (injection stroke), which is given in advance by the operator and determined by the mold and its characteristics.

[0047] ——Machine limits, such as the maximum motor torque, the current in the motor and the inverter, the maximum movement speed and the change in speed or the change in acceleration in mechanical parts such as the shaft and bearings.

[0048] ——Mold protection, that is, the maximum speed of the mold at the closing time and the maximum speed distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com