Numerical simulation method of complex profile extrusion process

A numerical simulation and extrusion process technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of frequent re-division of grids, self-contact of welding surfaces, etc., to reduce the simulation operation time and computer Effects on system resource usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

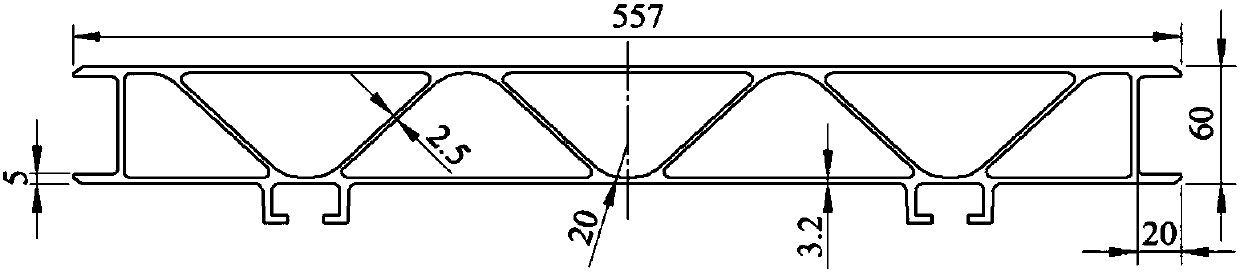

[0032] A numerical simulation method for the extrusion process of complex profiles. The complex profiles are large flat, wide and thin-walled hollow profiles, and their cross-sections are as follows: figure 2 As shown, the width is 557mm, the height is 60mm, and the cross-sectional area is 59.88cm 2 .

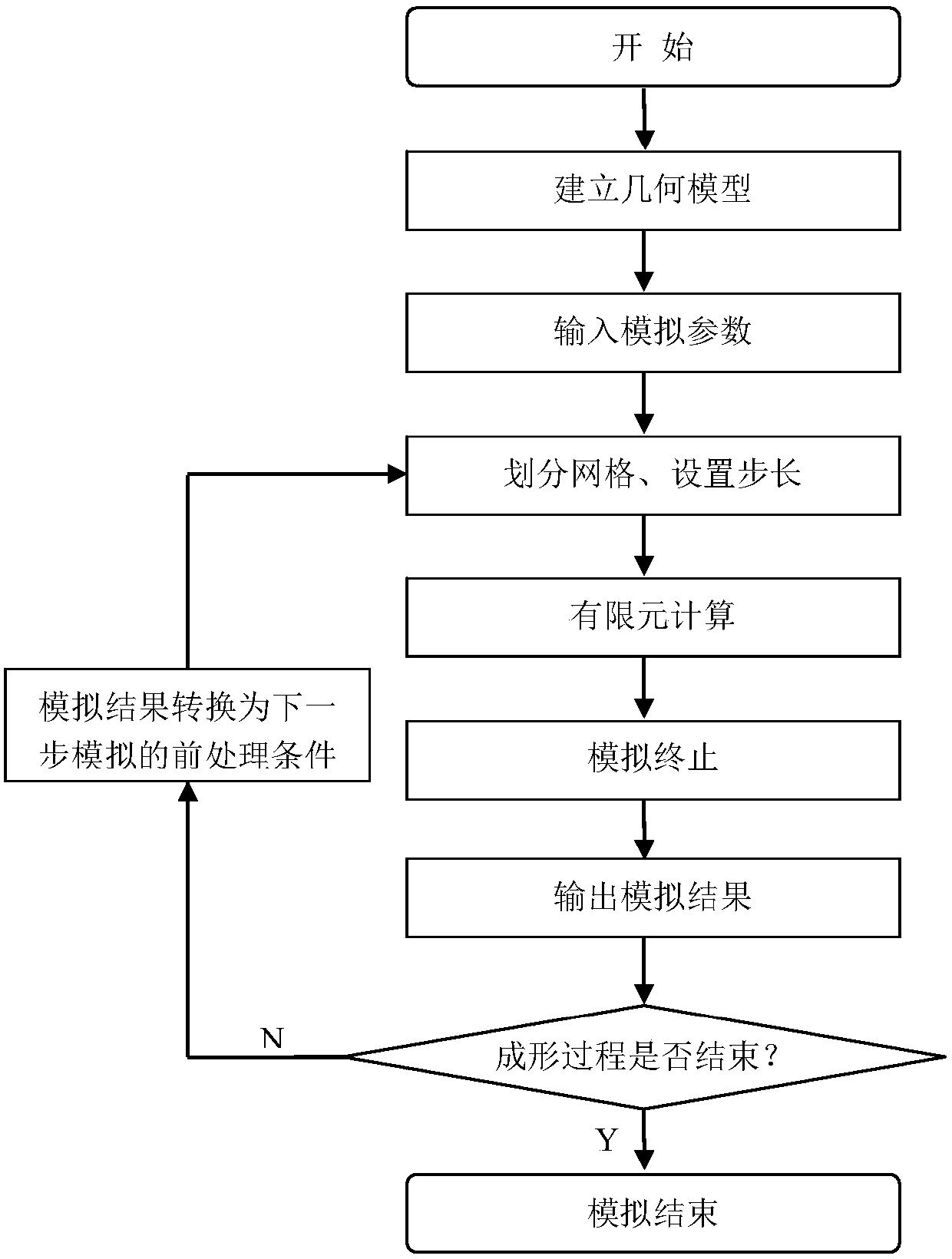

[0033] Such as figure 1 As shown, it is a flow chart of the finite element step-by-step method in the numerical simulation method of the complex profile extrusion process of the present invention.

[0034] A numerical simulation method for complex profile extrusion process, the steps are as follows:

[0035] 1. Before the simulation, first use the 3D CAD software to establish the 3D solid models of the billet, the shunt combined mold, and the thimble. The thimble in the extrusion system is a component that generates motion by applying the billet, which can be simplified as a cylindrical rigid surface. Structural elements irrelevant to analysis, such as screw holes, can be o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com