Bridge maintenance equipment capable of working automatically

A technology for automatic work and maintenance of equipment, which is applied to parts, electrical components, coupling devices, etc. Tightness, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

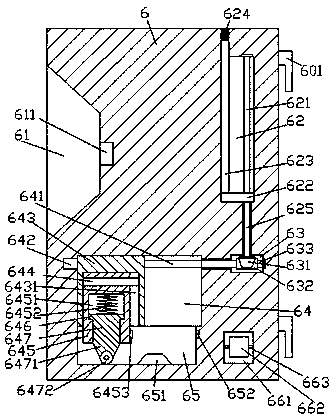

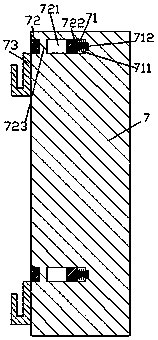

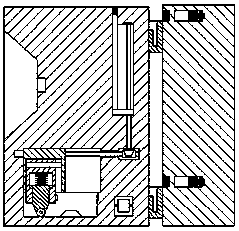

[0026] Such as Figure 1-Figure 8 As shown, an automatically working bridge maintenance equipment of the present invention includes a connecting frame body 6 and a hanging frame 7, and a control groove 61 is provided in the left end surface of the connecting frame body 6, and a control groove 61 is arranged in the control groove 61. An external electrical hole 611 is provided, and the electrical connection frame 6 is provided with a switch door 661 on the left end of the control slot 61. The left end of the switch door 661 is hinged by a hinge 663, and the external position of the switch door 661 is A handle 662 is provided at the handle 662, and the switch door 661 can be opened and closed. The hook 601 is correspondingly provided on the right end surface of the electrical connection frame 6, and the first sliding cavity is provided in the electrical connection frame 6. 64, the bottom end of the first sliding cavity 64 is provided with a guiding sliding groove 65, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com