NiTi memory alloy gradient porous personalized dental implant and manufacturing method thereof

A gradient porous, memory alloy technology, applied in dental implants, dentistry, dental prostheses, etc., can solve the problem of inability to match the mechanical requirements of dental implants, and achieve the effect of facilitating surgical installation, improving bonding strength, and preventing alveolar atrophy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

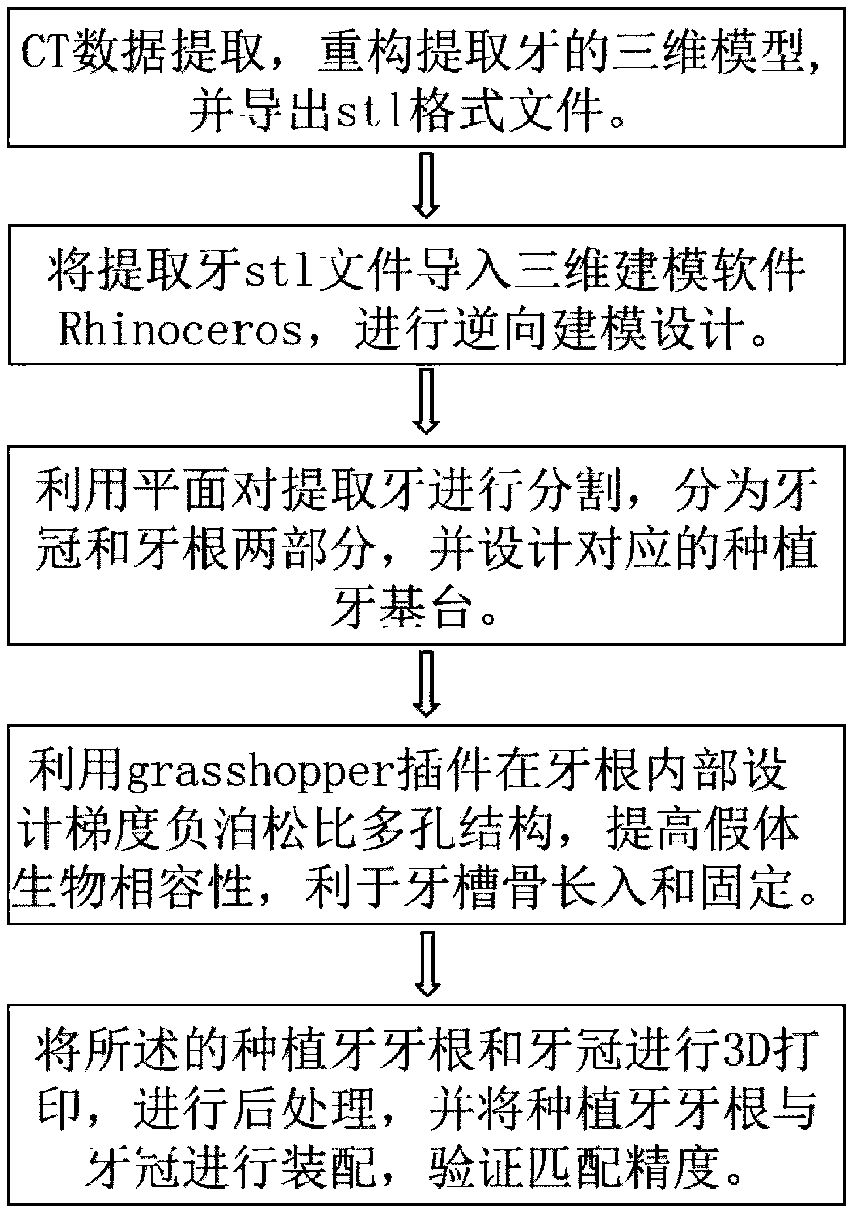

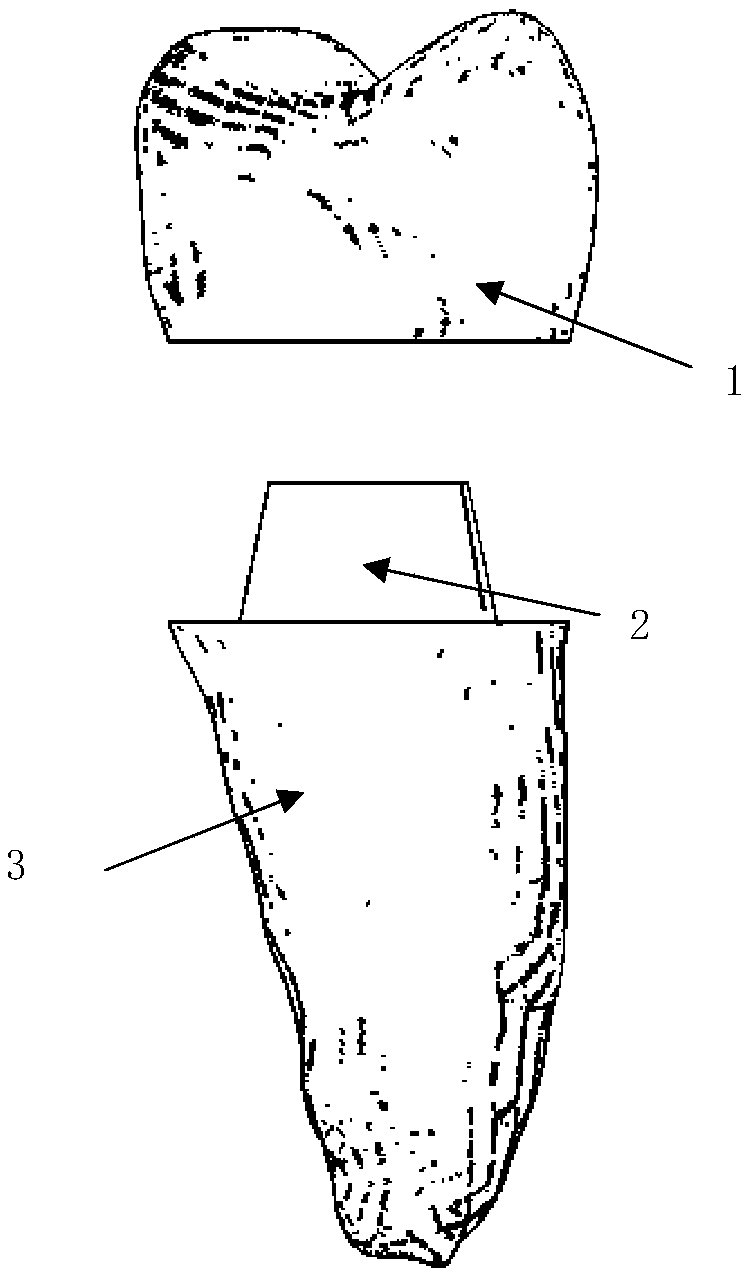

[0049] Such as figure 1 As shown, the NiTi memory alloy gradient porous personalized dental implant and its manufacturing method in this embodiment include the following steps:

[0050] The medical imaging data of the oral and maxillary diseased parts are collected by CT scanner, and the data in DICOM format are obtained. Import the DICOM format file into Mimics software, and edit the image in two-dimensional editing according to the threshold feature. Since the image threshold of the tooth root is very close to that of the alveolar bone, it is necessary to edit the image in detail according to the characteristics of the tooth root, delete the non-root image, and realize the continuous change of the root boundary. After fine editing, convert the two-dimensional data into three-dimensional data, and export the stl format file of the affected tooth.

[0051] Import the stl format file of the affected tooth into Geomagic studio software, adjust the mesh of the obtained affected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com