Dust removal device in wide-interval polar matching form and dust removal method

A dust removal device and spacing technology, applied in the direction of electrode cleaning, external electrostatic separator, electrostatic separation, etc., can solve the problems of high level of equipment transportation, installation and maintenance management, high purification efficiency without dust, complex dust removal equipment, etc., and achieve improvement The effect of power supply efficiency, large gas range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

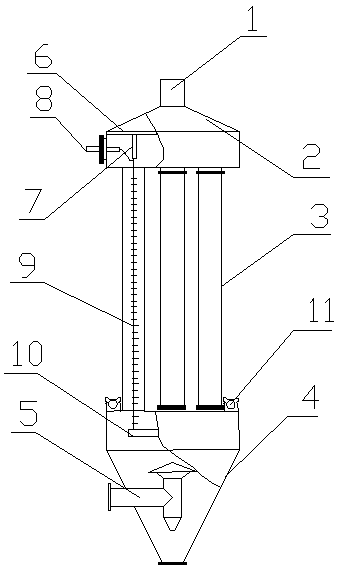

[0016] A kind of dust removal device in the form of wide-spacing pole matching, which consists of: an exhaust pipe 1, the exhaust pipe is connected to the air collecting cap 2, the described air collecting cap is connected to the collecting main pipe 3, and the described collecting main pipe is connected to the dust collector The bucket 4 is connected, and the ash bucket is connected with the uniform air pipe 5.

Embodiment 2

[0018] According to the dust removal device in the form of wide-spacing pole matching described in Example 1, an upper hanger 6, an insulating hanger 7, and a high-voltage incoming line 8 are installed in the wind collecting cap, and the upper hanger and the insulating hanger connection, the insulated hanger is connected to the high-voltage incoming line.

Embodiment 3

[0020] According to the dust removal device in the form of wide-spacing pole matching described in embodiment 1 or 2, a corona wire 9 is installed inside the collector tube, a lower hanger 10 is installed inside the ash hopper, and the corona wire Connect with the said lower hanger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com