Left portion positioning and clamping tool for automobile left and right side inner plate front assembly

A side wall inner panel, positioning and clamping technology, which is applied in the direction of auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of difficulty in ensuring the overall accuracy, high cost investment, and affecting the efficiency of production and processing, so as to improve the effective efficiency and product quality, high degree of automation, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

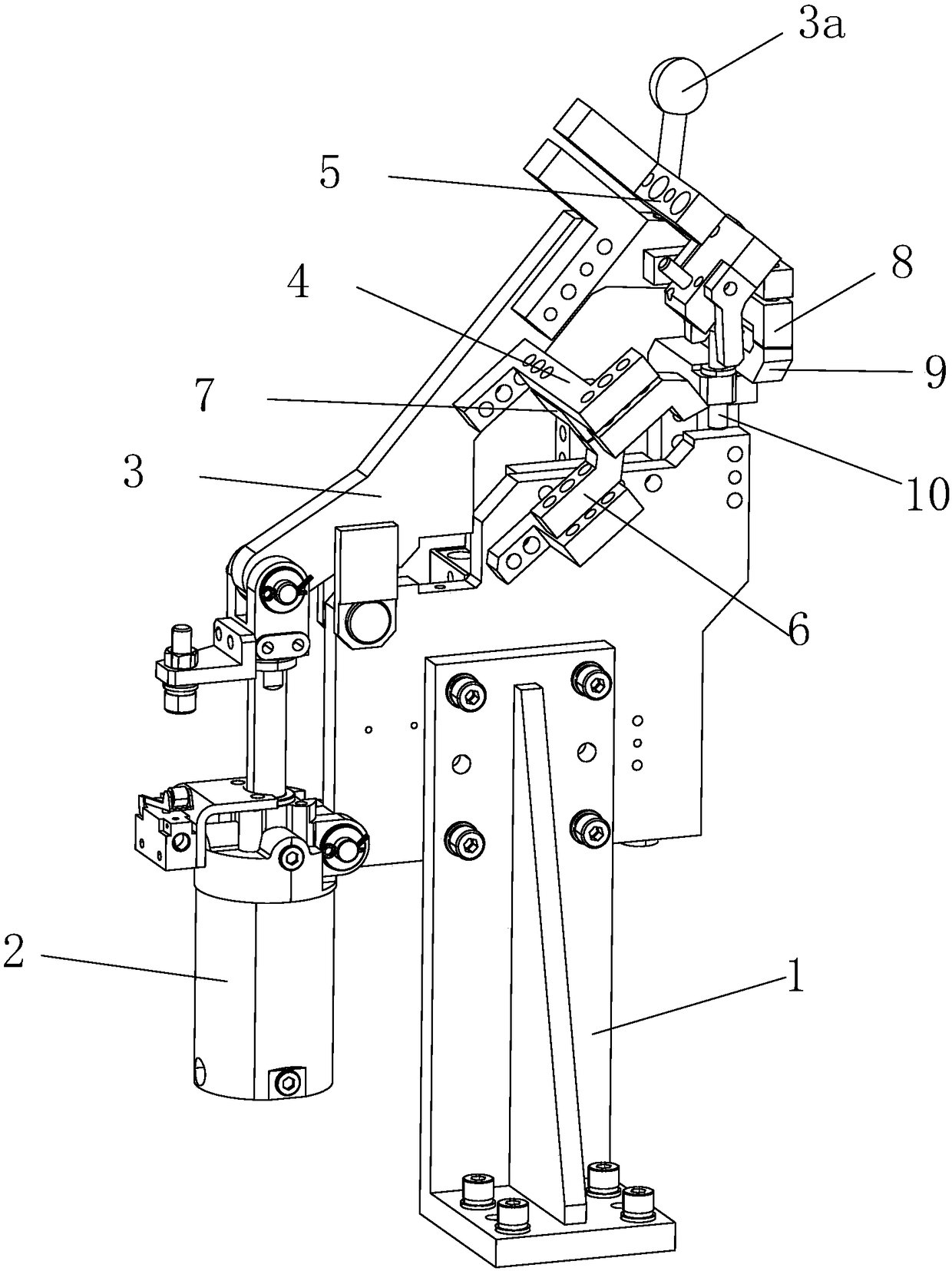

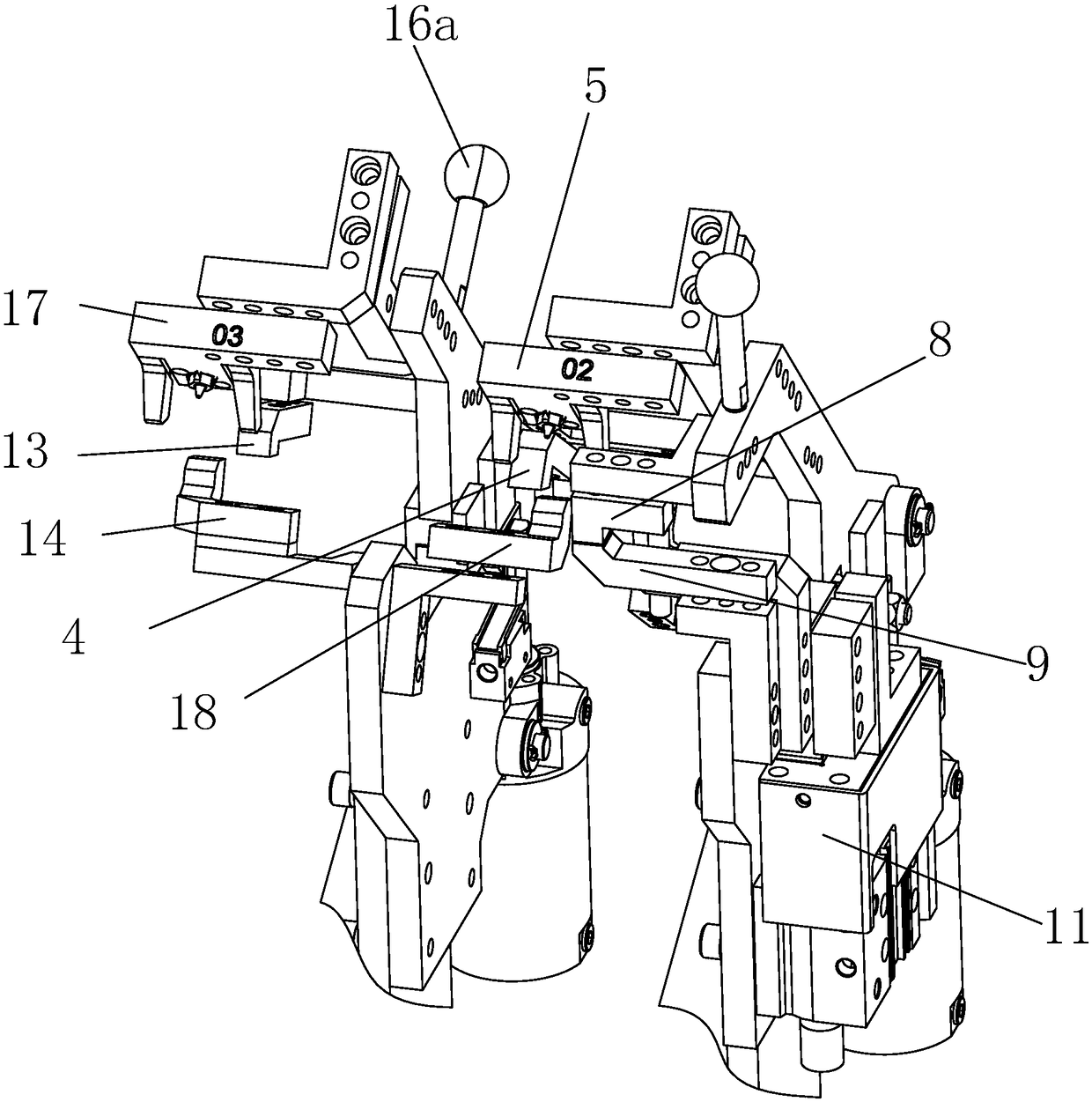

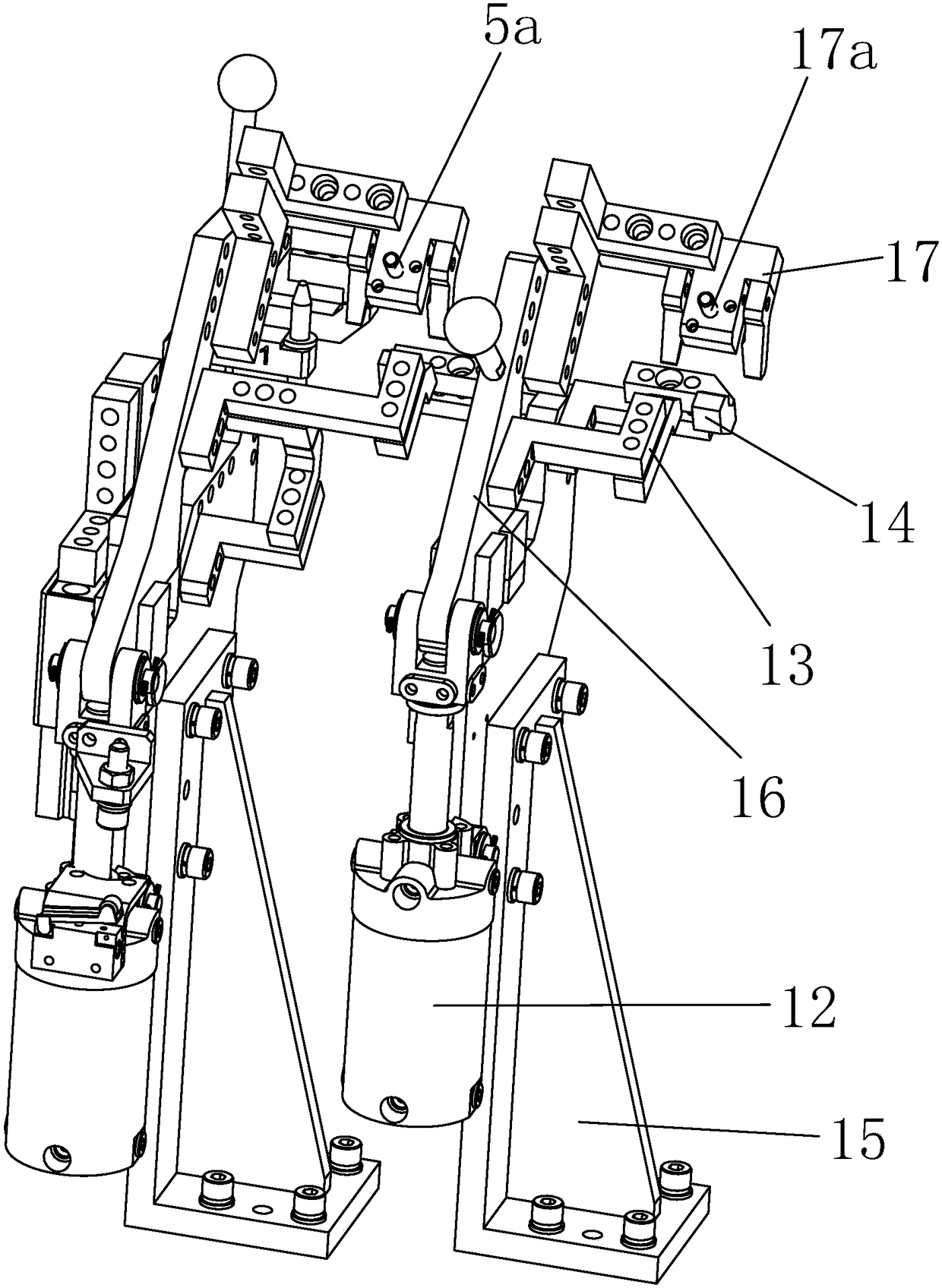

[0020] Such as Figure 1 to Figure 4 As shown, a left positioning and clamping tool for the front assembly of the left and right side panels of the automobile, including the left automatic positioning clamp, distributed on the right side of the left automatic positioning clamp and cooperated with the left automatic positioning clamp Position the clamped left auxiliary clamp. The invention has a reasonable structural design, uses a set of clamps to realize the positioning and clamping of all parts of the left part of the left and right side panel front assembly 20 of the entire automobile, and solves the traditional multi-process, multi-position, and multiple clamping The positioning method has the problems of complex operation, low precision and low efficiency, which ensures the moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com