Rectangular steel bar machining and grinding device

A rectangular, steel bar technology, applied in the direction of grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc., can solve the problems of inability to achieve grinding effects, poor grinding operations, and increased labor costs, etc., to achieve improved Grinding effect, improving sealing effect and improving safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

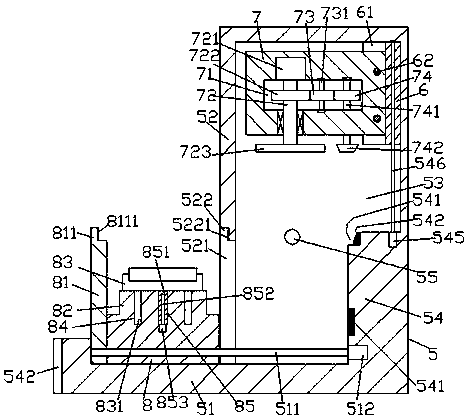

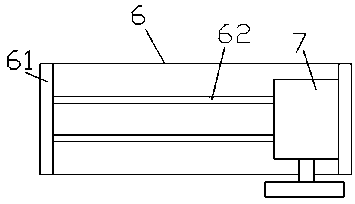

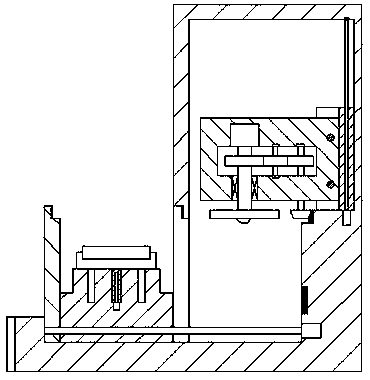

[0024] like Figure 1-Figure 5As shown, a processing and grinding device for a rectangular steel bar of the present invention includes a grinding frame 5 composed of a base 51 and a supporting frame 52. The supporting frame 52 is provided with a grinding cavity 53, and the supporting frame 52 is left A through groove 521 is formed on the side of the side end surface close to the base 51 , a protrusion 54 is fixed on the inner wall of the right side of the grinding cavity 53 opposite to the right side of the through groove 521 , and the top of the left side of the protrusion 54 is fixed. The edge is provided with an opening slot 541 extending front and rear, the right inner wall of the opening slot 541 is fixed with a conical toothed bar 542 extending along the front and rear extension direction of the opening slot 541, and the protruding portion 54 is far away from all the A first threaded rod 546 extending upward is provided on the top end face of one side of the opening groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com