Carriage connecting piece and carriage

A technology for connecting parts and carriages, applied in the field of carriages, can solve the problems of reducing structural bearing capacity, environmental pollution, and high welding costs, and achieve the effects of improving production efficiency, reducing production costs, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

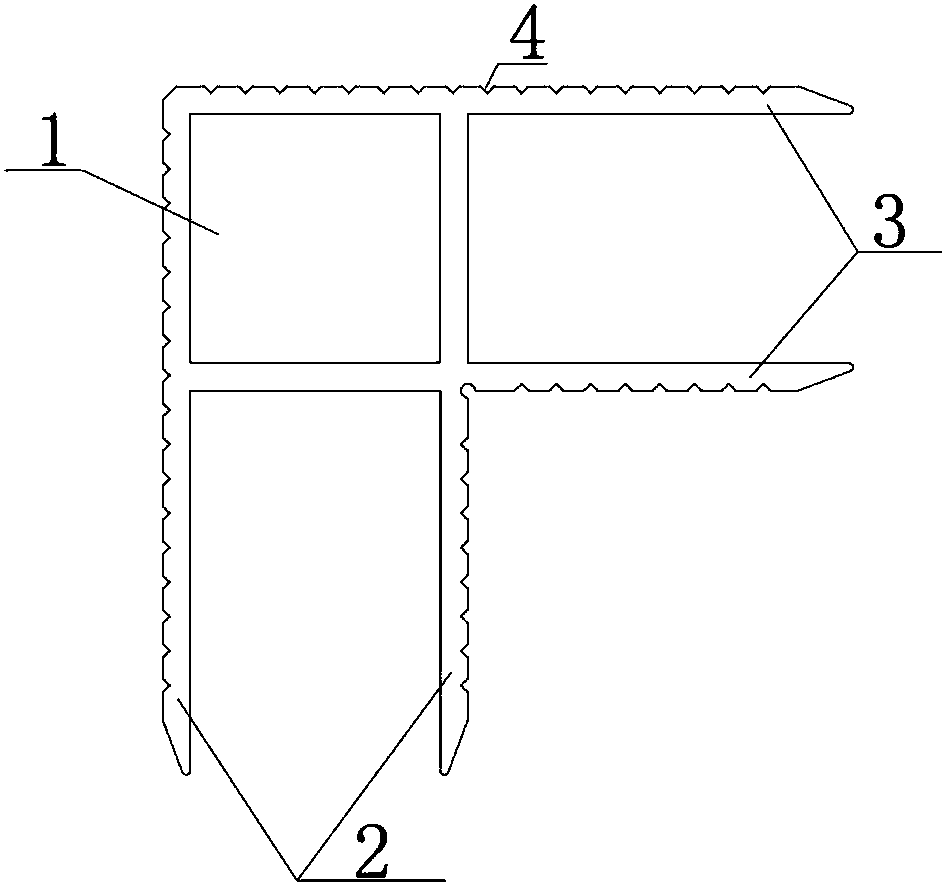

[0040] The invention discloses a compartment connector, such as figure 1 As shown, the compartment connector includes a connecting part 1 and a plug-in part 2, and the connecting part 1 is a tetrahedron. In this embodiment, the connecting part 1 is a cuboid, and its interior is a cavity. Inserting parts 2 are respectively fixed at the same end of the mutually perpendicular sides, and the inserting parts 2 are two parallel inserting boards 3 , and one end of the inserting boards 3 is fixedly connected with the side of the connecting part 1 . Glue grooves 4 are provided on the side of the connecting portion 1 that is not provided with the plug-in portion and the outer surface of the plug-in board 3. By setting the glue groove 4, the sealant can be placed in the glue groove, and the sealant connects the compartment profile with the compartment. The connecting pieces are glued together, realizing the fixed connection between the connecting pieces of the carriage and the profiles o...

Embodiment 2

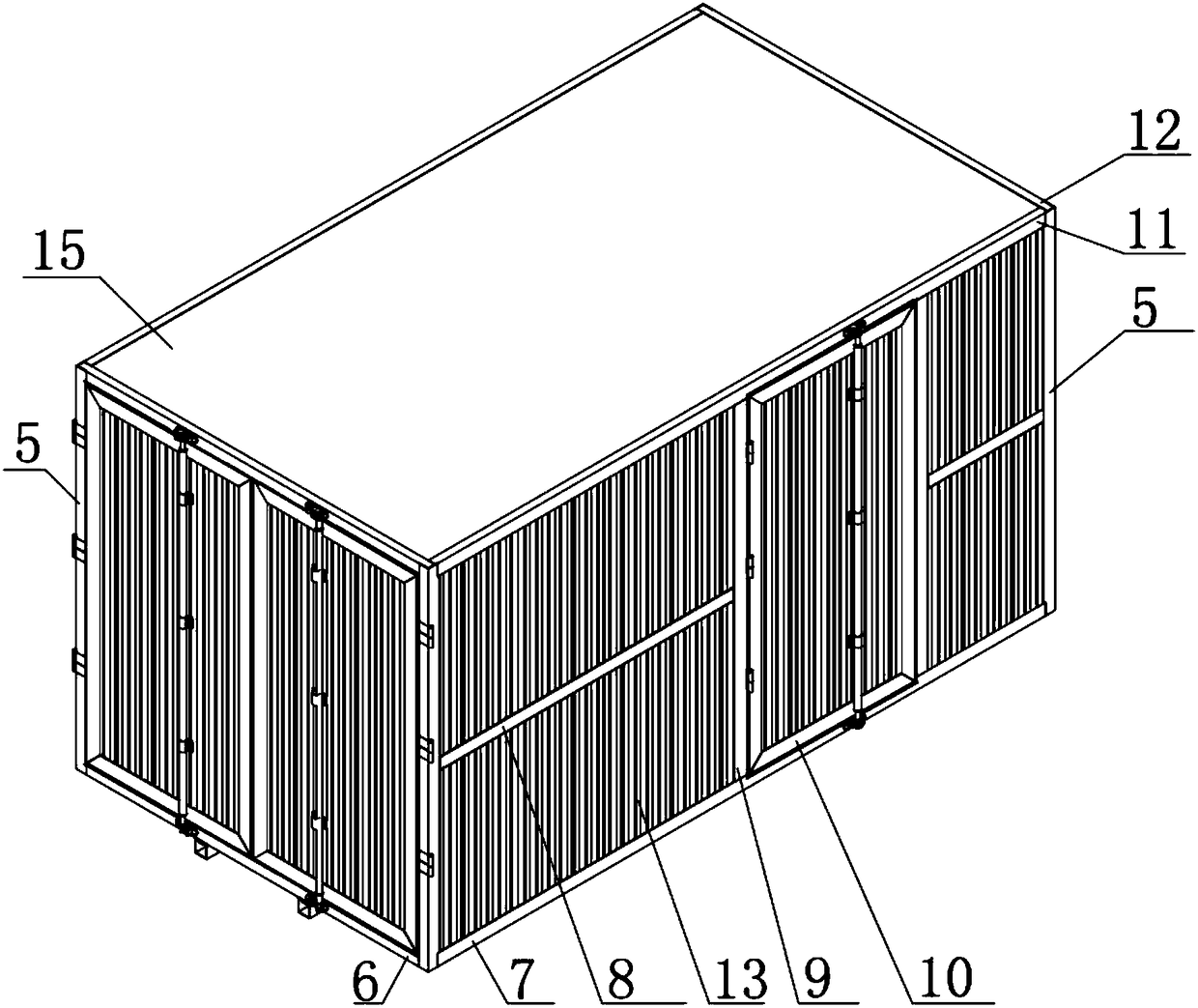

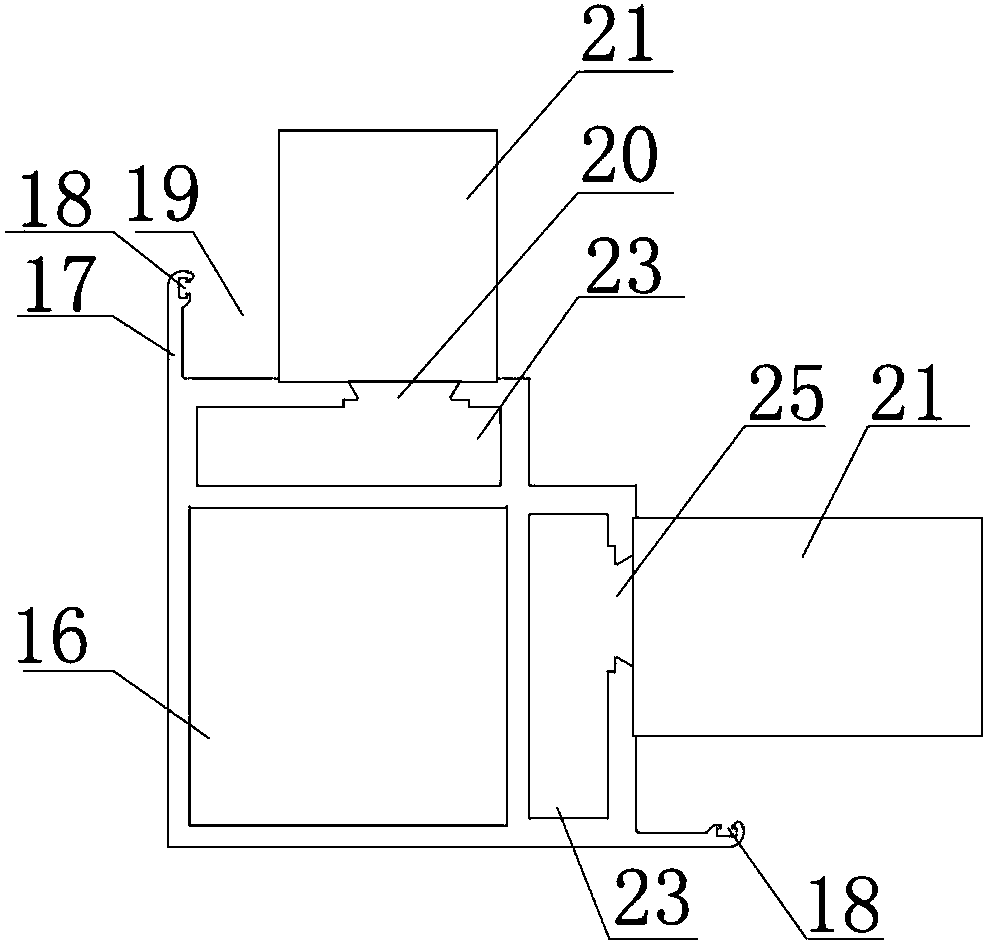

[0044] The invention also discloses a compartment comprising the above-mentioned compartment connector, such as figure 2 As shown, the compartment includes a compartment profile, a cladding plate 13, a compartment roof 15 and a pressure plate 21, and the compartment profile includes a compartment column 5, a compartment bottom longitudinal beam 6, a compartment bottom beam 7, a compartment top beam 11, a compartment top longitudinal beam 12, a compartment The middle vertical beam 8, the carriage middle column 9 and the carriage door frame 10. Wherein, the compartment column 5 and its adjacent compartment bottom longitudinal beam 6 and compartment bottom beam 7 are fixedly connected by a tee connector and a pressing plate 21, and the compartment column 5 and its adjacent compartment top beam 11 and compartment top longitudinal beam 12 are fixedly connected to each other. The space is fixedly connected by a three-way connector and a pressing plate 21. The three-way connector i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com