Reinforced rotational-flow sand setting tank

A cyclone sand settling and tank body technology, applied in chemical instruments and methods, water pollutants, centrifugal separation of water/sewage treatment, etc. Enhance the effect of swirl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

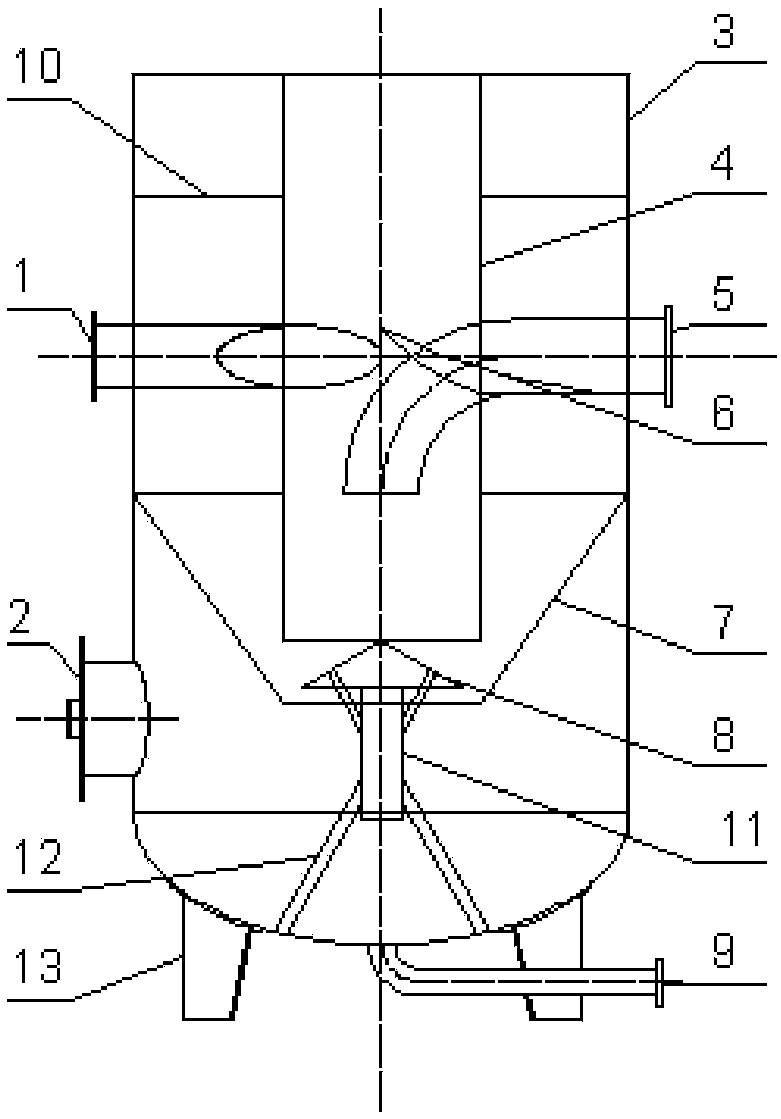

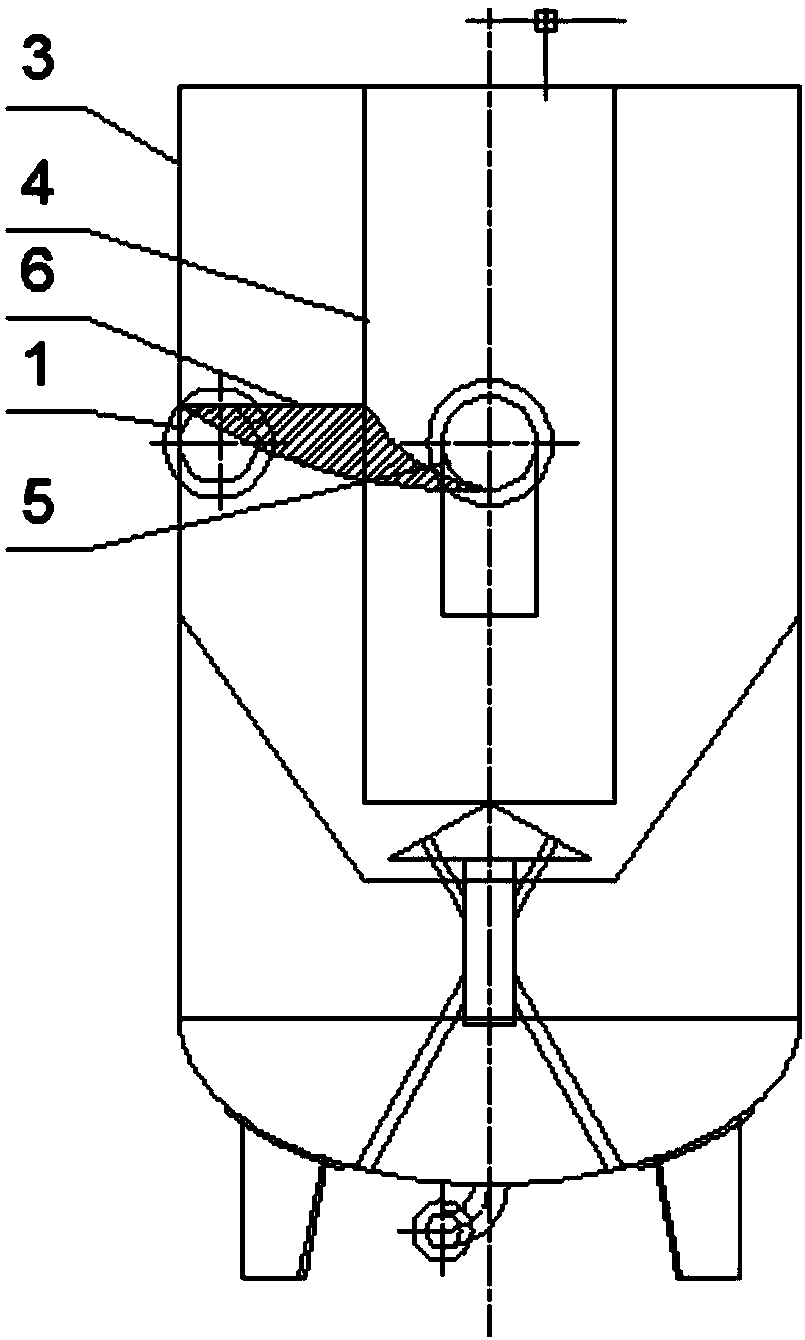

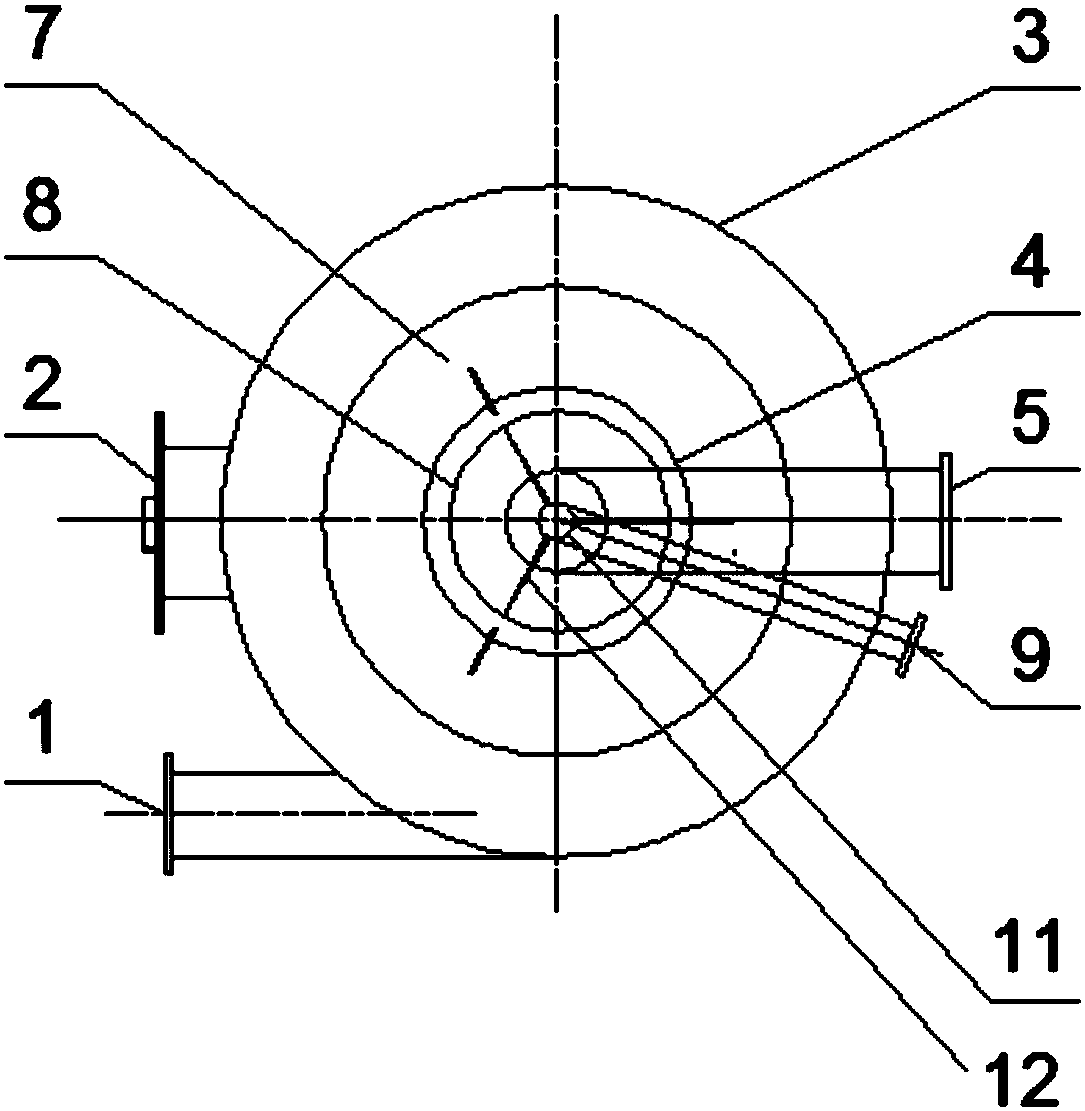

[0032] see Figure 1-7 As shown, the enhanced cyclone grit chamber of the present invention includes a tank body 3, the upper part of the tank body 3 is provided with a water inlet pipe 1 and a water outlet pipe 5, and the connection between the water inlet pipe 1 and the water outlet pipe 5 and the tank body 3 is a water inlet respectively. (not marked) and the water outlet (not marked), the outlet pipe 4 continues to pass through the inner cylinder 4 to extend to its inside, the bottom of the tank body 3 is provided with a manhole 2, and the bottom of the tank body 3 is provided with a sand discharge pipe 9, the tank body The inside of 3 is provided with inner cylinder 4, annular inclined plate 7 and deflector cap 8 from top to bottom, and deflector 6 is arranged between inner cylinder 4 and tank body 3, and deflector 6 is helical (similar to helical blade ), one end of the deflector 6 is located above the water inlet, the other end is close to the lower side of the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com