Production device for ethyl alpha-cyanoacrylate

A technology for ethyl cyanoacrylate and a production device, which is applied in the preparation of carboxylic acid nitrile, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of complex production devices and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

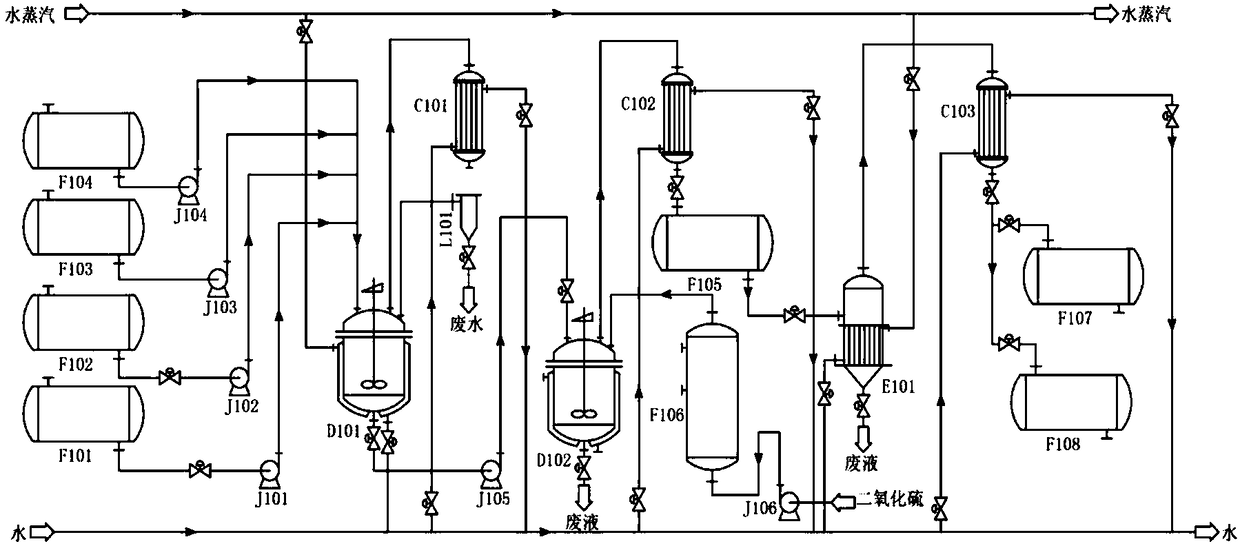

Image

Examples

example 1

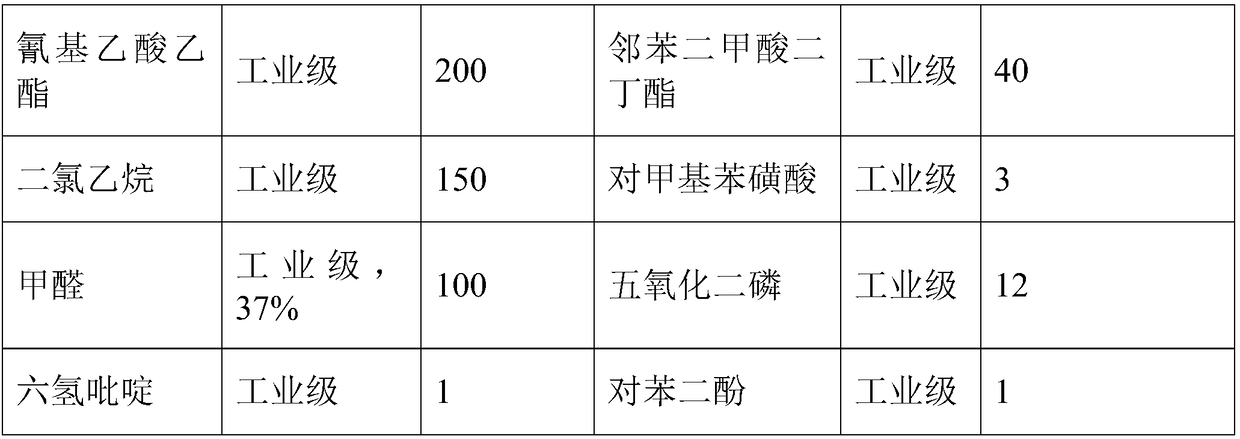

[0008] Production raw materials and dosage

[0009]

[0010] The production equipment of ethyl α-cyanoacrylate mainly includes: storage tank (F101), storage tank (F102), storage tank (F103), storage tank (F104), raw material pump (J101), raw material pump (J102), Raw material pump (J103), raw material pump (J104), reactor (D101), delivery pump (J105), water separator (L101), condenser (C101), condenser (C102), condenser (C103), pyrolysis Kettle (D102), storage tank (F105), buffer tank (F106), vacuum pump (J106), rectification tower (E101), non-boiling range product receiving tank (F107), finished product receiving tank (F108), among which, storage tank (F101) is used to store ethyl cyanoacetate, storage tank (F102) is used to store dichloroethane, storage tank (F103) is used to store formaldehyde, and storage tank (F104) is used to store dibutyl phthalate , The storage tank (F105) is used to store crude products, wherein the height of the cone bottom of the storage tank (F...

example 2

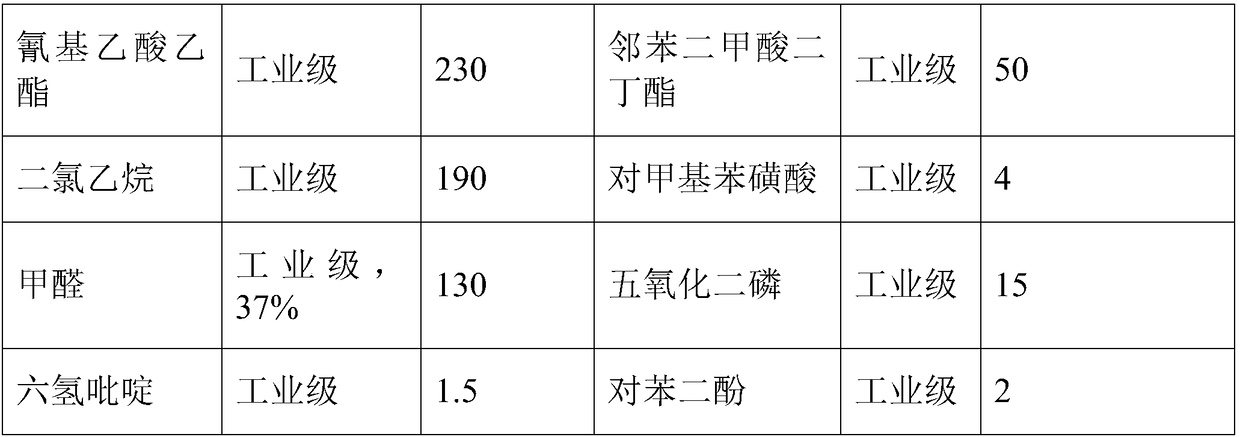

[0015] Production raw materials and dosage

[0016]

[0017] The production equipment of ethyl α-cyanoacrylate mainly includes: storage tank (F101), storage tank (F102), storage tank (F103), storage tank (F104), raw material pump (J101), raw material pump (J102), Raw material pump (J103), raw material pump (J104), reactor (D101), delivery pump (J105), water separator (L101), condenser (C101), condenser (C102), condenser (C103), pyrolysis Kettle (D102), storage tank (F105), buffer tank (F106), vacuum pump (J106), rectification tower (E101), non-boiling range product receiving tank (F107), finished product receiving tank (F108), among which, storage tank (F101) is used to store ethyl cyanoacetate, storage tank (F102) is used to store dichloroethane, storage tank (F103) is used to store formaldehyde, and storage tank (F104) is used to store dibutyl phthalate , The storage tank (F105) is used to store crude products, wherein the height of the cone bottom of the storage tank (F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com