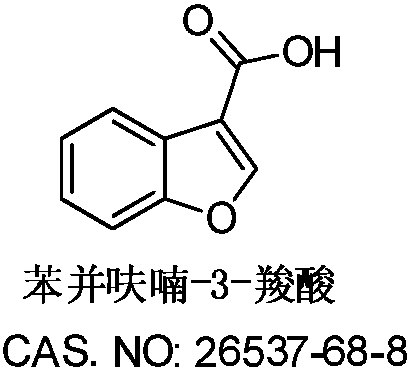

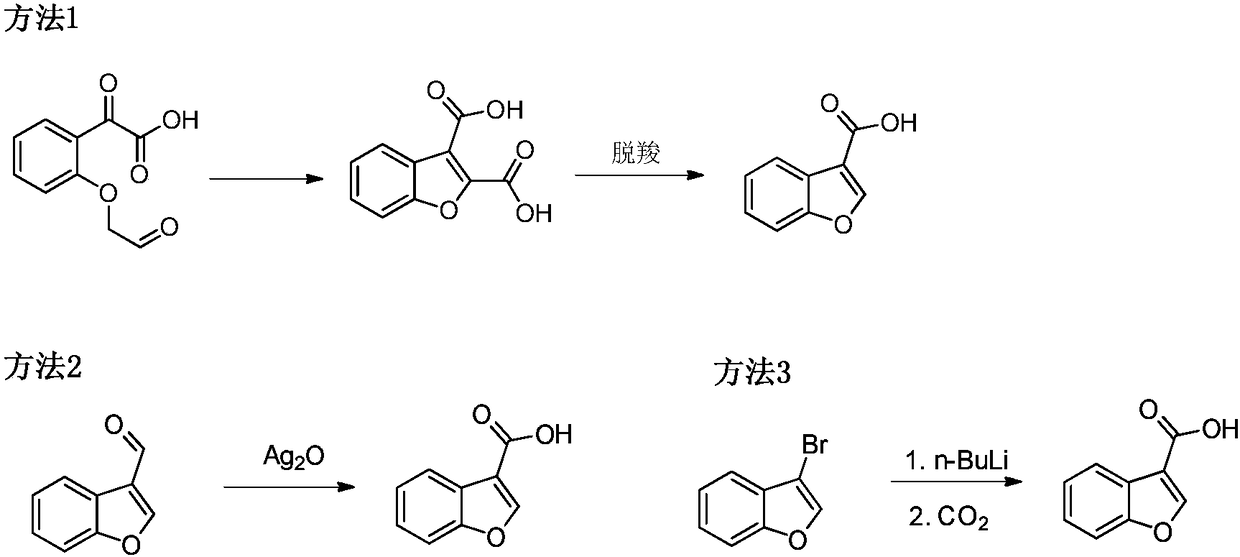

Preparation method of benzofuran-3-carboxylic acid

A technology of benzofuran and carboxylic acid, which is applied in the field of preparation of benzofuran-3-carboxylic acid, can solve the problems of low reaction yield, harsh reaction conditions and high price, and achieves the effects of high yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

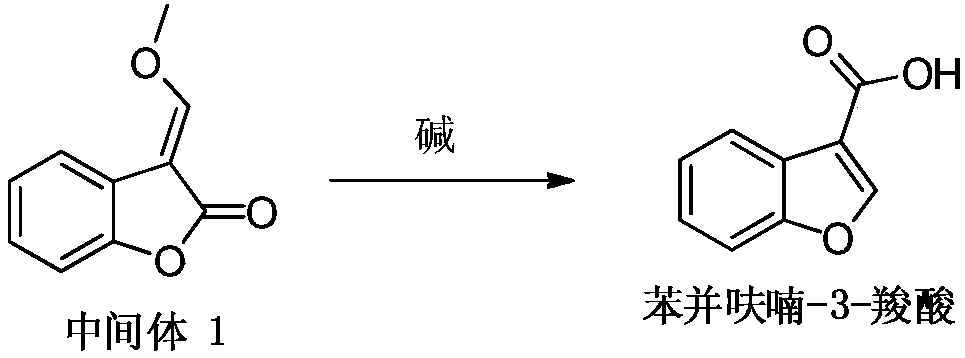

Method used

Image

Examples

example 1

[0016] 152 grams of o-hydroxyphenylacetic acid, 500 grams of acetic anhydride and 250 grams of trimethyl orthoformate were added to the reaction flask, and the temperature was raised to 80-100° C. for 6 hours. The solvent was distilled off under reduced pressure to obtain a yellow solid. After adding 500 g of methanol to the solid and stirring to dissolve, control the temperature at 0-10° C., add dropwise 180 g of 30% sodium hydroxide solution, after the dropping is complete, raise the temperature to 50-60° C., and react for 3-6 hours. Recover methanol under reduced pressure, add 300 grams of drinking water to the residue, control the temperature of the solution below 30°C, add dropwise 160 grams of 30% hydrochloric acid to adjust the pH to 1-2, cool down to 0-10°C, crystallize for 3 hours, filter, and wash the solid with water , dried in vacuo to obtain 158 g of off-white solid with a yield of 97.5%.

example 2

[0018] 152 grams of o-hydroxyphenylacetic acid, 500 grams of acetic anhydride and 250 grams of trimethyl orthoformate were added to the reaction flask, and the temperature was raised to 80-100° C. for 6 hours. The solvent was distilled off under reduced pressure to obtain a yellow solid. Add 300 grams of 95% ethanol to the solid, control the temperature at 10-20°C, add dropwise 500 grams of 20% sodium carbonate solution, after the drop is complete, raise the temperature to 80-100°C, and react for 16 hours. Cool down to below 30°C and add about 230g of 30% hydrochloric acid dropwise to adjust the pH to 3-4, cool down to 10-20°C, crystallize for 3 hours, filter, wash the solid with water, and dry in vacuo to obtain 149g of off-white solid with a yield of 92.0% .

example 3

[0020] 152 grams of o-hydroxyphenylacetic acid, 500 grams of acetic anhydride and 250 grams of trimethyl orthoformate were added to the reaction flask, and the temperature was raised to 80-100° C. for 6 hours. The solvent was distilled off under reduced pressure to obtain a yellow solid. Add 500 grams of anhydrous methanol to the solid, add 300 grams of 20% sodium methoxide solution dropwise at a controlled temperature of -5-0° C., and keep the reaction for 5 hours after dropping. Add 300 grams of drinking water dropwise, continue to stir and react at 30-40°C for 6 hours, recover methanol under reduced pressure, add 500 grams of drinking water to the residue, drop the temperature below 30°C, and add about 140 grams of 30% hydrochloric acid to adjust the pH to 2-3. The temperature was lowered to crystallize, filtered, the solid was washed with water, and dried in vacuo to obtain 156 g of off-white solid with a yield of 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com