Perfluoropolyether silane dendritic compound as well as preparation method thereof and film containing dendritic compound

A perfluoropolyether silane and dendritic technology, applied in polyether coatings, biocide-containing paints, coatings, etc., can solve problems such as poor adhesion and peeling, and achieve pollution prevention, firm attachment, and strong adhesion Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

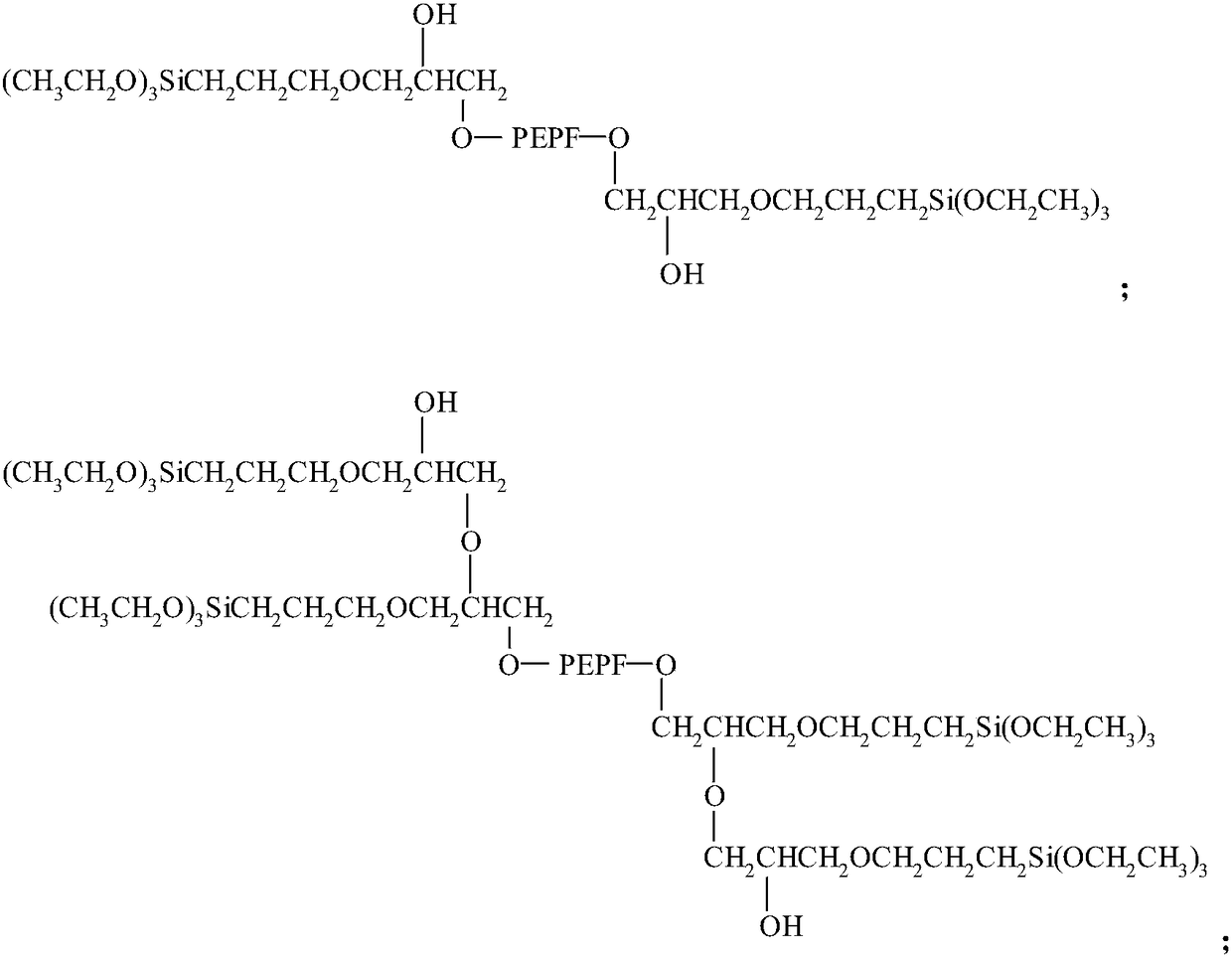

[0040] This embodiment provides a perfluoropolyether silane dendritic compound, the chemical formula of the perfluoropolyether silane dendritic compound is:

[0041] The subscripts m and n in the formula are each independently a natural number 1, 2 or 3, wherein,

[0042] PFPE stands for perfluoropolyether group;

[0043] R is a bridging group;

[0044] X is a hydrolyzable group.

[0045] Apparently, the perfluoropolyether silane dendrimers contain perfluoropolyether groups (PFPE) and thus have good hydrophobicity and oleophobicity, and at the same time, the silane dendrimers group The silicon-oxygen-silicon chemical bond can be directly formed with the glass so as to stably improve the direct binding force between the perfluoropolyether silane dendritic compound and the glass. Therefore, the perfluoropolyether silane dendritic compound can be used to form a film that can not only prevent the surface of the glass panel from being polluted by external dirt and user's fin...

Embodiment 2

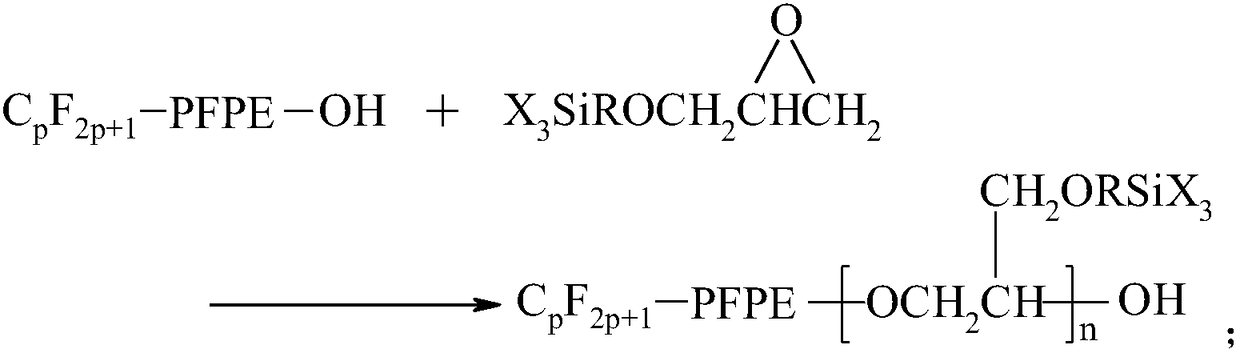

[0054] This embodiment provides a perfluoropolyether silane dendritic compound, the chemical formula of the perfluoropolyether silane dendritic compound is:

[0055] The subscripts p and n in the formula are each independently a natural number 1, 2 or 3, wherein,

[0056] PFPE stands for perfluoropolyether group;

[0057] R is a bridging group;

[0058] X is a hydrolyzable group.

[0059]In this embodiment, the perfluoropolyether group is a perfluorinated group (that is, substantially all C-H bonds are replaced by C-F bonds), which may include straight chain, branched chain and / or cyclic structures, and may be saturated or unsaturated. Specific examples of the perfluoropolyether group are disclosed in Chinese patent CN200780030231.5, so details will not be repeated here.

[0060] The hydrolyzable groups are usually chlorine groups, alkoxy groups, acyloxy groups, etc., and when these groups are hydrolyzed, silanol (Si(OH) 3 ), and combine with inorganic substances to for...

Embodiment 3

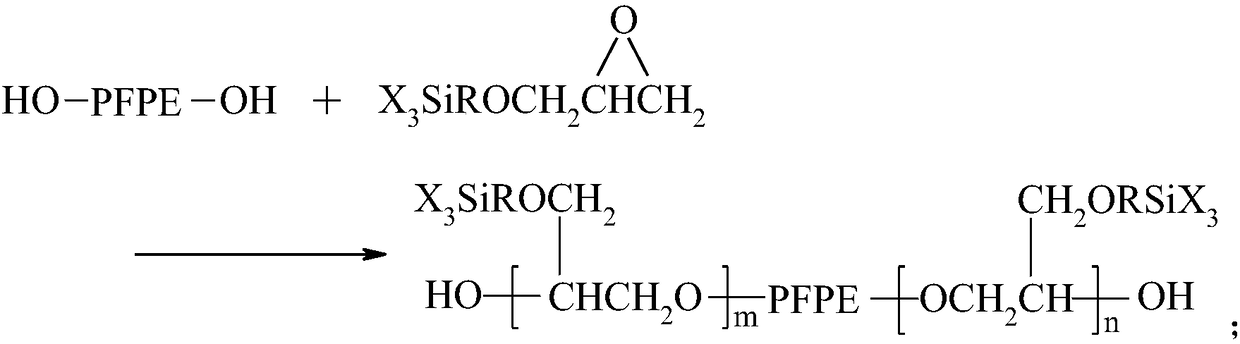

[0067] This embodiment provides a method for preparing the perfluoropolyether silane dendrimers described in Embodiment 1, the preparation method includes chemical reaction I:

[0068]

[0069] In the formula,

[0070] PFPE stands for perfluoropolyether group;

[0071] R is a bridging group;

[0072] X is a hydrolyzable group;

[0073] The subscripts m and n are each independently a natural number 1, 2 or 3.

[0074] In this example, trifluoromethanesulfonic acid was added as a catalyst during the chemical reaction I to accelerate the reaction process. The principle of the chemical reaction I is: the hydroxyl group (-OH) in the reactant HO-PFPE-OH is in trifluoromethanesulfonic acid (CF 3 SO 3 Under the catalytic action of H), the reactant is attacked epoxy bond in . Preferably, the chemical reaction I is carried out under nitrogen protection at a temperature of 60-120°C.

[0075] In this embodiment, the perfluoropolyether group is a perfluorinated group (that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com