Single sand suction device adopting anti-abrasion structure and sand suction method

A one-way, suction port technology, used in parts of pumping devices for elastic fluids, pumps for special fluids, non-variable-capacity pumps, etc., can solve problems such as difficult processing and assembly processes, and reduced head and efficiency. , to achieve the effect of good noise reduction, noise reduction and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

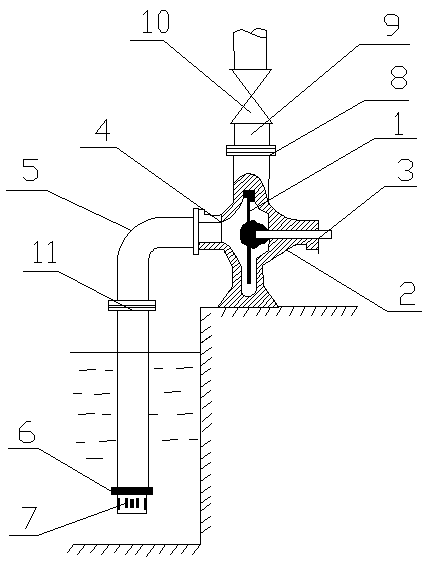

[0017] A single sand suction device adopting an anti-abrasion structure, which consists of: a regulating valve 10, the regulating valve is connected to the discharge pipe 9, the discharge pipe is connected to the discharge port 8, and the discharge port is connected to the discharge port through the pipe The pump casing 2 is connected, the pump casing is connected with the suction pipe 5, the suction pipe is connected with the connection flange 11, and the connection flange is connected with the one-way bottom valve 6 through the pipe.

Embodiment 2

[0019] According to the single sand suction device with an anti-abrasion structure described in Embodiment 1, the impeller 1 and the pump shaft 3 are installed inside the pump casing, the impeller is connected to the pump shaft, and the pump casing is connected to the suction Port 4 is connected.

Embodiment 3

[0021] According to the single sand suction device with an anti-abrasion structure described in Embodiment 1 or 2, the one-way base valve is connected to the filter screen 7, and a group of strip holes are evenly processed around the filter screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com