Online density measurement instrument for constant-temperature duel-pressure vibration tube type drilling fluid and measurement method

A technology of drilling fluid density and dual pressure, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of unfavorable pressure management drilling construction and low accuracy, and achieve the effect of eliminating measurement errors and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

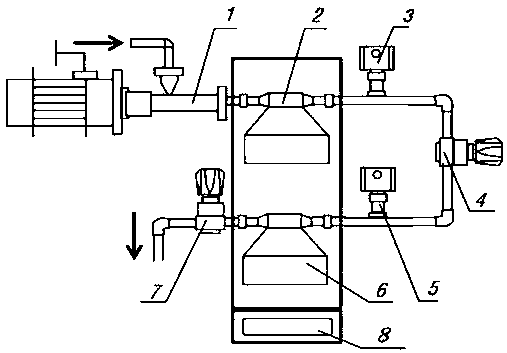

[0023] Embodiment 1. With reference to attached figure 1 , connect the inlet pipe of screw pump 1 to the drilling fluid container, screw pump 1 is connected in series with Coriolis mass flowmeter I2, back pressure valve I4, Coriolis mass flow meter II6, and back pressure valve II7 through pipelines, and the pressure The sensor I3 and the pressure sensor II5 are respectively connected in parallel on the upstream and downstream pipelines of the back pressure valve I4, and the Coriolis mass flowmeter I2 and the Coriolis mass flowmeter II6 are installed in the semiconductor constant temperature container 8, forming the The constant temperature dual pressure vibrating tube drilling fluid density online measuring instrument.

[0024] The present invention adopts the measuring method steps of the constant-temperature dual-pressure vibrating tube drilling fluid density on-line measuring instrument: ①The drilling fluid is pumped into the pipeline by the screw pump, and flows through th...

Embodiment 2

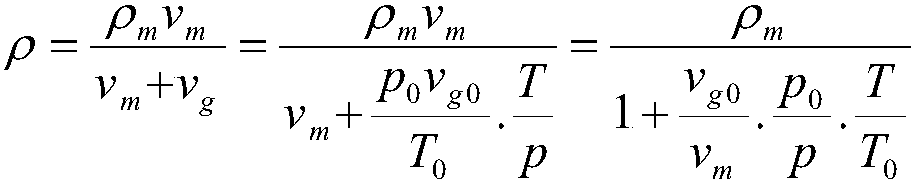

[0050] Embodiment 2. Adjust the temperature of the semiconductor constant temperature container to the temperature of the measured drilling fluid, continuously circulate the drilling fluid in the container at a certain flow rate, adjust the back pressure valve I4 and the back pressure valve II7, and make the two vibrating tube densitometers 2 and 6 pressures are P 1 and P 2 , measure the density value ρ of two vibrating tube densitometers 2 and 6 1 and ρ 2 ;according to P 1 ,P 2 , ρ 1 , ρ 2 and the instantaneous value of drilling fluid temperature T to calculate the solid-liquid phase density ρ of drilling fluid m The instantaneous value of :

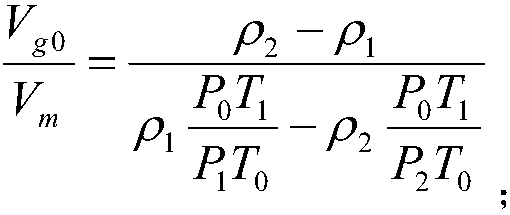

[0051] And the gas-liquid volume ratio under the standard state:

[0052] Continuous determination of these P 1 ,P 2 , ρ 1 , ρ 2 Instantaneous value of T and T, real-time measurement and continuous recording of drilling fluid solid-liquid phase density and gas-liquid volume ratio change process under standard conditions,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com