Micro-nano structured optical element and its preparation method and application

A micro-nano structure and optical element technology, applied in optical elements, optics, nanotechnology, etc., can solve problems such as increasing the transmission of blue-violet light, and achieve the effects of excellent mechanical strength, weather resistance, and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

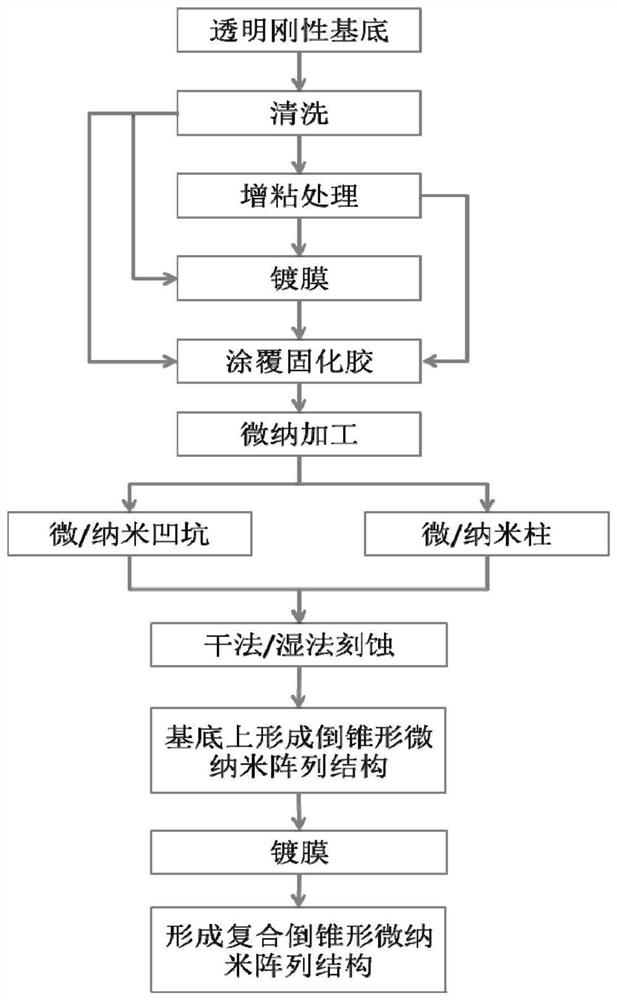

[0062] A specific process of the preparation method of the micro-nano structured optical element of the present invention is as follows: figure 1 As shown, the present invention provides a kind of preparation method of micro-nano structure optical element, comprises steps:

[0063] Step 1), providing a transparent rigid substrate.

[0064] As an example, step 1) further includes the steps of performing a cleaning process and an adhesion-increasing process on the transparent rigid substrate.

[0065] Preferably, the cleaning process includes one or a combination of two or more of a liquid phase cleaning process, a gas phase cleaning process and an ultraviolet light cleaning process.

[0066] Further, the gas phase cleaning process includes one of gas plasma cleaning and ozone cleaning, and the surface of the transparent rigid substrate is activated while cleaning, so as to improve the bonding force between the transparent rigid substrate and the subsequent process film.

[00...

Embodiment 1

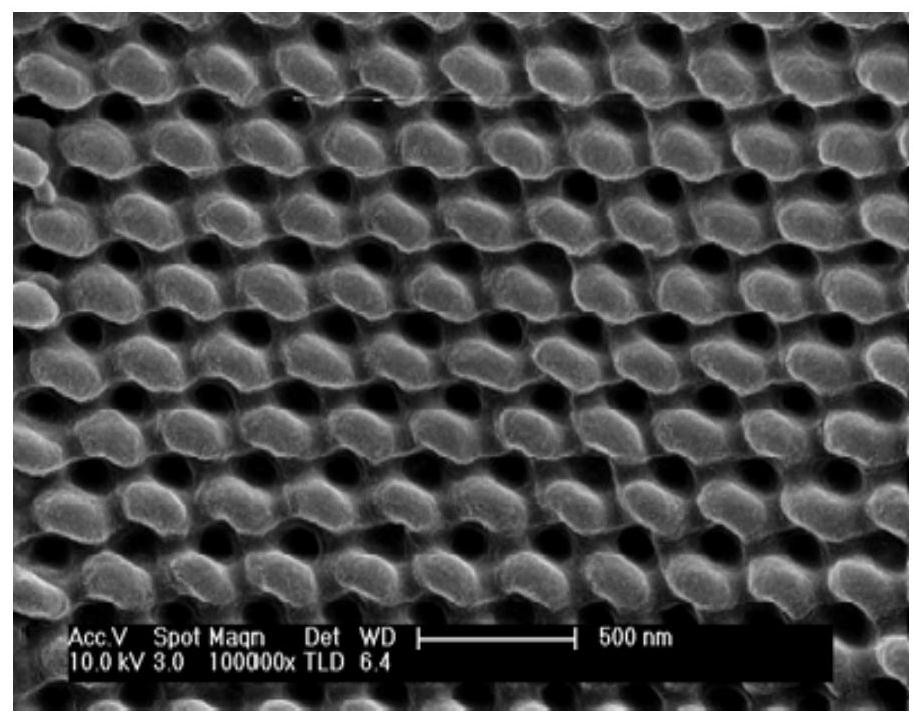

[0084] This embodiment provides a nanoimprinting method to prepare an inverted tapered micro-nano structure array on a sapphire cover plate, such as Figure 2a As shown, 21 is an array of inverted conical micro-nano structures, and 22 is a sapphire cover plate. This structure can achieve broad-spectrum anti-reflection and anti-reflection effects, and also has good mechanical strength and anti-wear performance. It has application prospects in lighting, display, showcase and other fields.

[0085] The following describes this embodiment in detail. The preparation method of the micro-nano structured optical element of this embodiment includes steps:

[0086] The first step: cleaning and surface treatment of the sapphire cover. Take a sapphire cover plate, put it into a mixed solution of concentrated sulfuric acid and hydrogen peroxide at a ratio of 3:1 at a temperature of 125 degrees Celsius, and clean it for 10 minutes. Subsequently, it was baked in an oven at 120 degrees Cel...

Embodiment 2

[0092] In this embodiment, the inverted conical micro-nano structure array is combined with the coating to form a composite inverted conical micro-nano structure array on the sapphire cover plate, such as Figure 3a shown, where 31 is SiO 2 The coating layer has an array of inverted conical micro-nano structures, and 32 is a sapphire cover plate. The structure can achieve broad-spectrum anti-reflection and anti-reflection effects, and at the same time has a certain inhibitory effect on the transmission of blue-violet light, and has application prospects in lighting, display and other fields.

[0093] The following describes this embodiment in detail. The preparation method of the micro-nano structured optical element of this embodiment includes steps:

[0094] The first step: cleaning and surface treatment of the sapphire cover. Take a sapphire cover plate, put it into a mixed solution of concentrated sulfuric acid and hydrogen peroxide at a ratio of 3:1 at a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com