Powder puff and powder puff case as well as preparation method of powder puff

The technology of a powder puff and a box body is applied in the directions of cosmetic powder containers, dressing containers, packaging items, etc., which can solve the problems of uneven makeup application on the powder puff, and achieve the effects of uniform makeup application, prevention of pollution of the powder puff, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

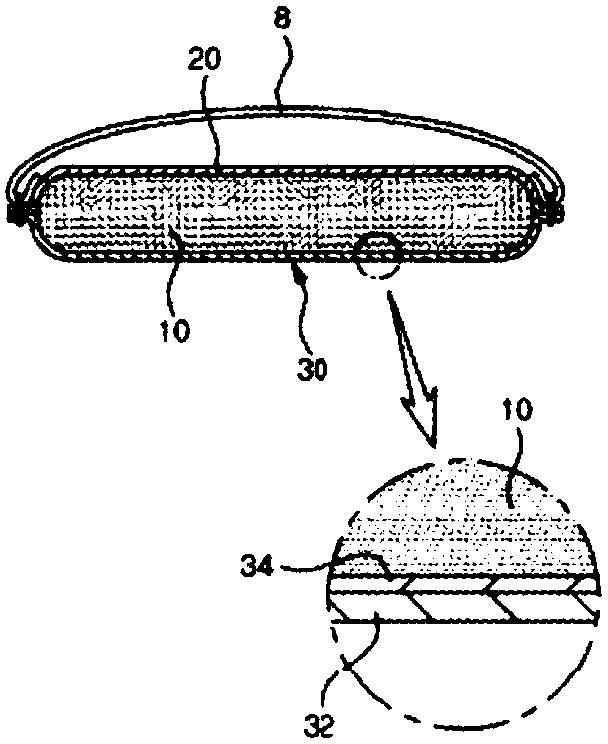

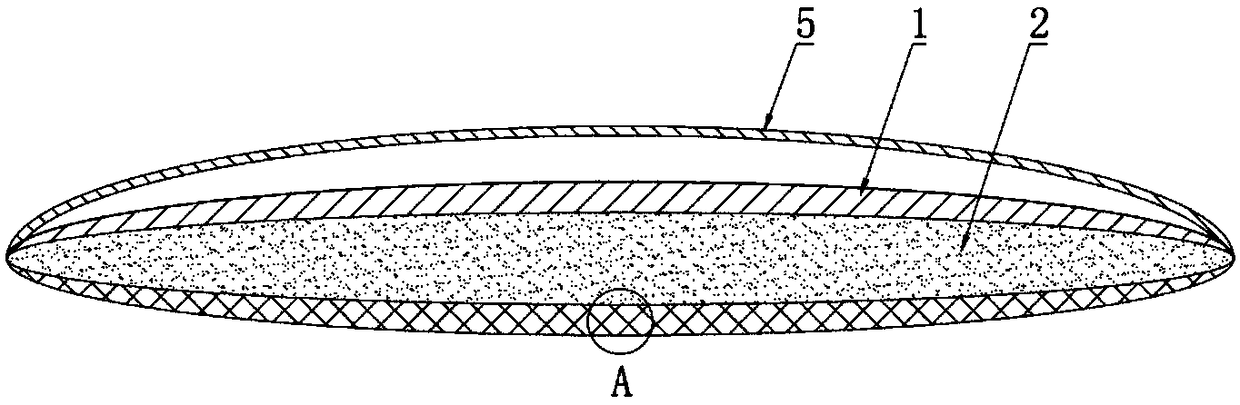

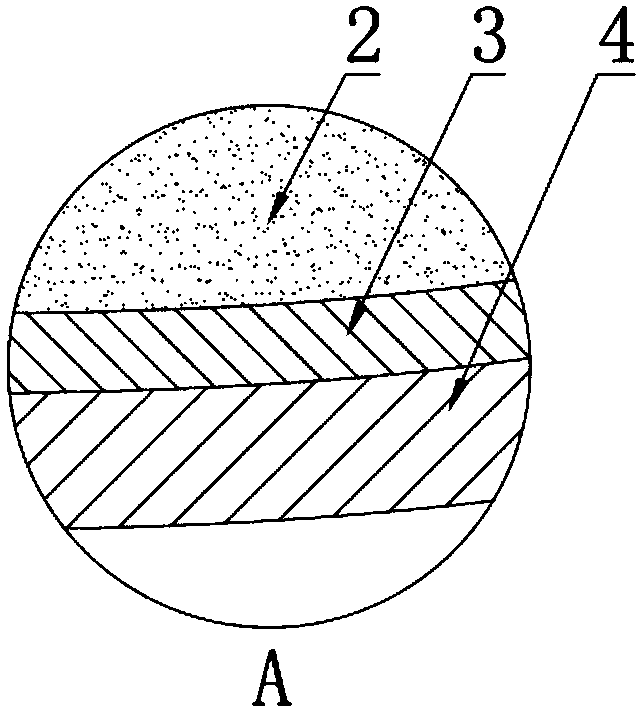

[0038] like figure 2 and image 3 as shown, figure 2 It is a schematic diagram of the state of cutting a cut for the puff of Example 1.

[0039] The powder puff of embodiment 1 is made up of the cover sheet 1 of disc-shaped 1mm, the elastic spacer 2 of disc-shaped 3mm, the puff layer 4 of disc-shaped natural latex film layer 3 and disc-shaped 2mm.

[0040] Specifically, the cover sheet 1 is laid on the lower surface of the elastic gasket 2, the natural latex film layer 3 is coated on the upper surface of the elastic gasket 2, and the puff layer 4 is laid on the natural latex film layer 3. The upper surface of the powder puff layer 4 is the powder upper area.

[0041] Wherein, the cover sheet 1 is leather, the elastic gasket 2 is sponge, and the powder puff layer 4 is polyurethane elastomer.

[0042] The cover sheet 1 is provided with a finger buckle 5, preferably a leather finger buckle.

Embodiment 2

[0044] The powder puff of embodiment 2 is made up of disc-shaped 0.8mm cover sheet 1, disc-shaped elastic gasket 2 of 2.5mm, disc-shaped natural latex film layer 3 and disc-shaped 1.8mm puff layer 4 .

[0045] Specifically, the cover sheet 1 is laid on the lower surface of the elastic gasket 2, the natural latex film layer 3 is coated on the upper surface of the elastic gasket 2, and the puff layer 4 is laid on the natural latex film layer 3. The upper surface of the powder puff layer 4 is the powder upper area.

[0046] Wherein, the cover sheet 1 is a cotton layer, the elastic gasket 2 is a sponge, and the powder puff layer 4 is a silica gel.

[0047] The cover sheet 1 is provided with a finger buckle belt 5, preferably a cotton elastic belt.

Embodiment 3

[0049] The powder puff of embodiment 3 is made up of the puff layer 4 of disc-shaped 1.2mm cover sheet 1, disc-shaped 3.5mm elastic gasket 2, disc-shaped natural latex film layer 3 and disc-shaped 2.2mm .

[0050] Specifically, the cover sheet 1 is laid on the lower surface of the elastic gasket 2, the natural latex film layer 3 is coated on the upper surface of the elastic gasket 2, and the puff layer 4 is laid on the natural latex film layer 3. The upper surface of the powder puff layer 4 is the powder upper area.

[0051] Wherein, the cover sheet 1 is a velvet layer, the elastic gasket 2 is a sponge, and the powder puff layer 4 is a silica gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com