Method for increasing magnesite flotation recovery rate

A flotation recovery rate and magnesite technology, applied in flotation, solid separation and other directions, can solve the problems of difficulty in high efficiency and stability, low concentrate rate, etc., and achieve the effects of ensuring product quality, improving MgO recovery rate, and efficient removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

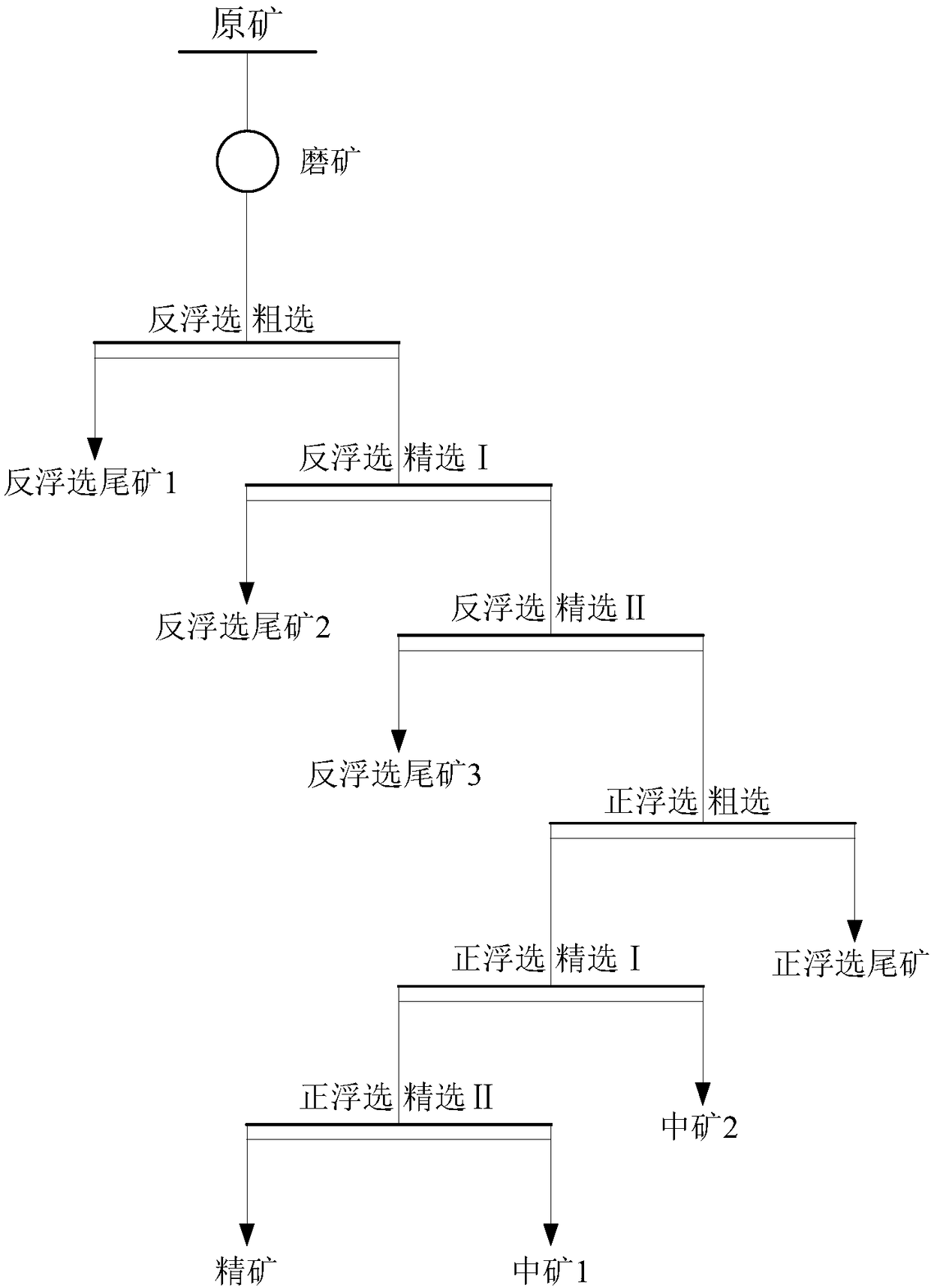

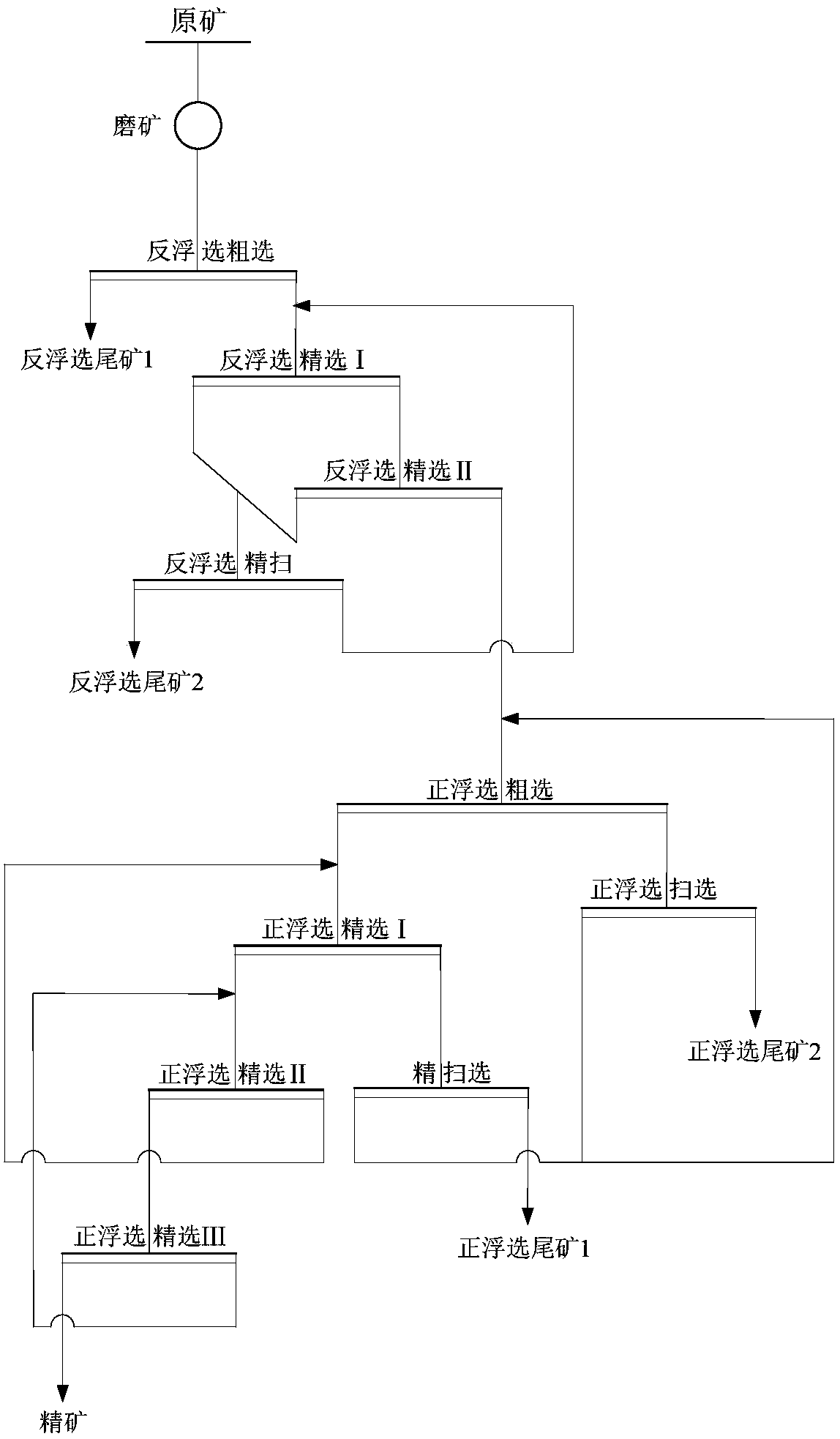

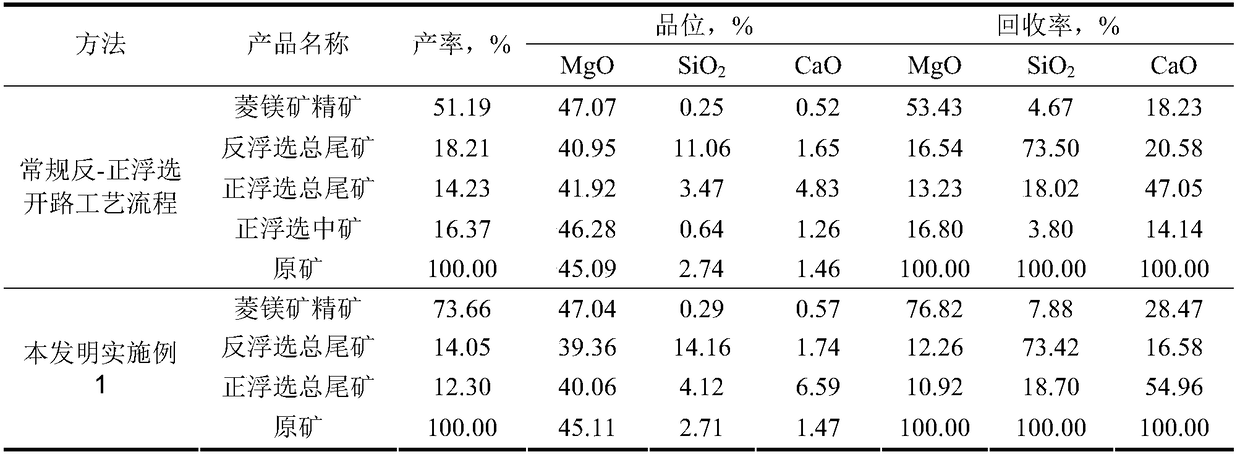

[0030] Such as figure 2 Shown, a kind of method that improves magnesite flotation recovery, may comprise the steps:

[0031] Step a. Grinding the raw magnesite ore until it is basically dissociated, so as to obtain the raw ore slurry whose grinding fineness is less than 0.074 mm and the mass accounts for 60-90 wt%.

[0032]Step b, adding reverse flotation reagents to the raw ore pulp, and performing reverse flotation desiliconization operations; the reverse flotation desiliconization operations include first performing a reverse flotation roughing, and the foam in the reverse flotation roughing directly forms a reverse flotation Flotation tailings 1, and then carry out two reverse flotation concentration (ie reverse flotation concentration Ⅰ and reverse flotation concentration Ⅱ) on the underflow of reverse flotation roughing, and then all or part of the reverse flotation concentration The foams are combined together for a reverse flotation fine sweep, and the underflow of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com