Miniature clutch structure and manipulator provided with same

A manipulator and manipulator technology, applied in the field of manipulators, can solve the problems of inability to achieve effective envelope grasping, limited application range of manipulators, lack of under-actuating capability, etc., and achieve the effects of small loss, simple structure and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

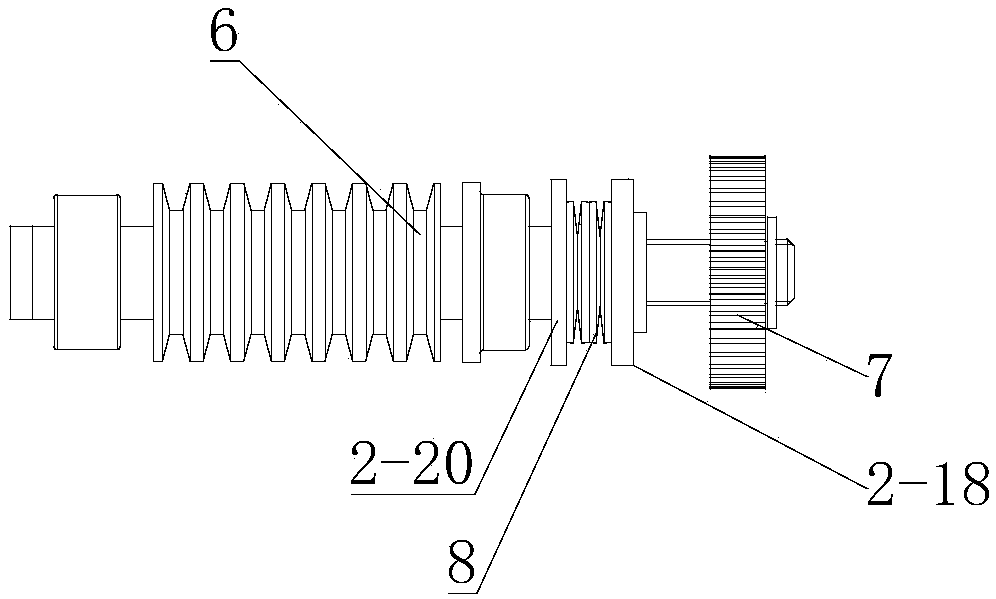

[0064] Such as figure 1 Shown, it is; Wherein, described miniature clutch structure comprises:

[0065] The first threaded connector 6 has external threads;

[0066] The second threaded connector 7 has an internal thread and is in a threaded state with the first threaded connector;

[0067] The spring 8 has one end abutting against the first threaded connection and the other end abutting against the second threaded connection; and the spring is in a compressed state.

[0068] In this way, the spring in the compressed state will give a certain moment to the abutting first threaded connection and the second threaded connection (the first threaded connection and the second threaded connection compress the spring to a certain extent by abutting against it) , so that the first threaded connection and the second threaded connection are difficult to separate by screwing (screwing is essentially the frictional movement of the threaded surfaces in contact with each other, in the firs...

Embodiment 2

[0071] Like the micro-clutch structure described above, the difference in this embodiment is that the first threaded connecting piece is a threaded rod with an abutment portion arranged thereon, the second threaded connecting piece is a threaded cap, and the The spring is sheathed on the threaded rod, with one end abutting against the abutting portion and the other end abutting against the side of the threaded cap.

[0072] In this way, the threaded cap is fixed on the threaded rod by screwing the thread; the threaded rod can be driven to rotate by rotating the threaded cap, and after the threaded rod is subjected to a certain resistance, the driving of the threaded cap is separated; it is simple and convenient; The combination of pair and spring can make it generate a large driving torque. In this way, a clutch structure with a large driving torque can be generated through a micro-thread pair and a spring, thereby increasing the scope of application of the clutch structure. Fo...

Embodiment 3

[0075] Like the micro-clutch structure described above, the difference in this embodiment is that the first threaded connection is a threaded rod, the second threaded connection is a hollow threaded column, and the spring is sleeved on the On the threaded post; the threaded rod is provided with an abutting portion, and the threaded post is provided with an abutting projection, one end of the spring abuts against the abutting portion, and the other end abuts against the abutting projection rise.

[0076] In this way, the threads of the threaded rod and the threaded column have more contact, and their threads are less likely to be damaged, thereby increasing their service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com