Flame-retardant material

A technology of flame retardant materials and composite flame retardants, applied in the field of materials, to achieve the effects of enhanced flame retardant effect, convenient use, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

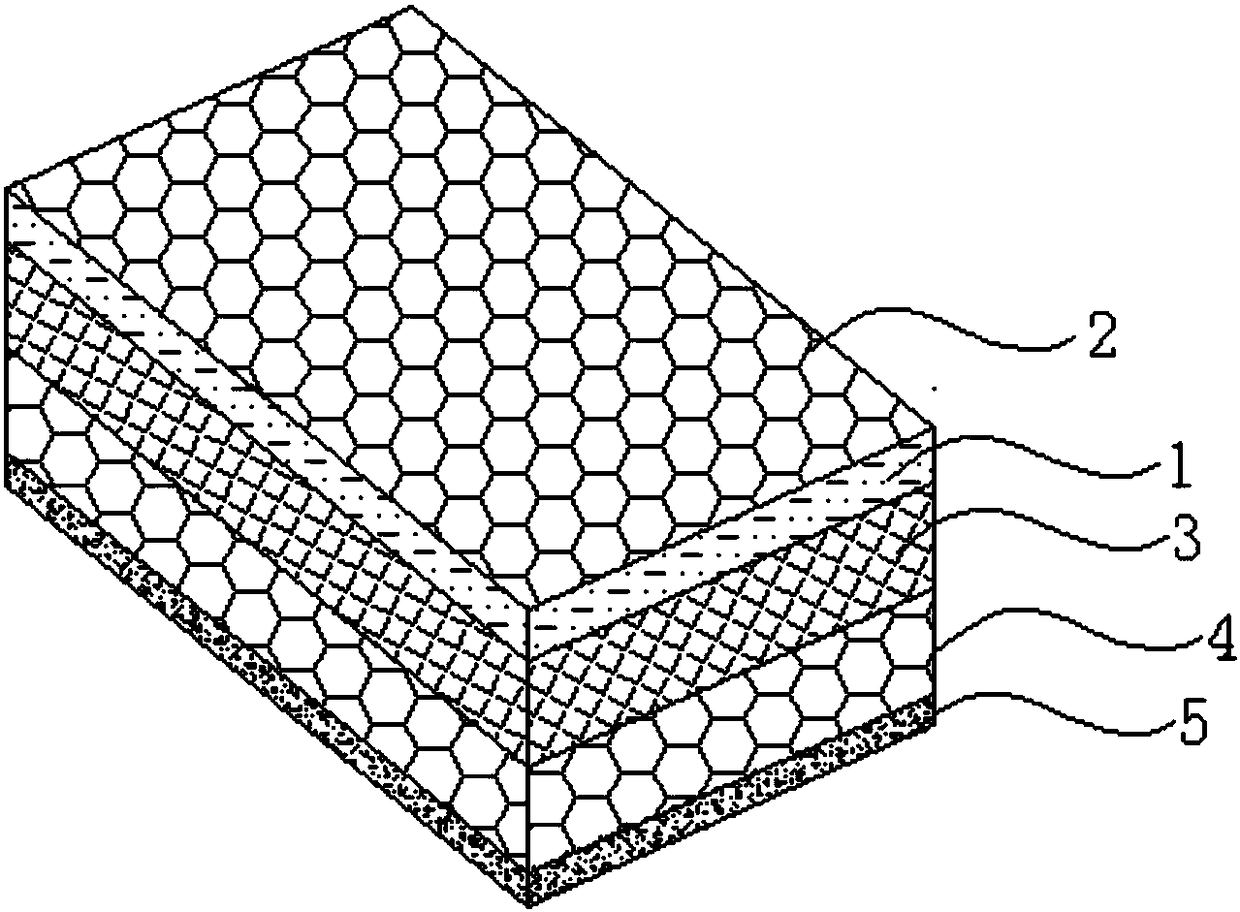

[0021] Such as figure 1 Shown, a kind of flame retardant material of the present invention, comprises the graphite sheet 1 that thickness is 2mm, and graphite sheet 1 upper layer is provided with honeycomb copper mesh 2, and the copper wire diameter in copper mesh 2 is 0.5mm; The lower layer of the sheet 1 is provided with a composite flame retardant layer 3, and the thickness of the composite flame retardant layer 3 is 5mm; Specifically, the hexagon formed by the honeycomb has a side length of 2 cm. Wherein, the fireproof bottom layer 4 is made of rigid polyurethane foam.

[0022] More specifically, the composite flame retardant layer 4 contains the following powders uniformly mixed by mass fraction: 65% potassium nitrate, 4% basic magnesium carbonate, 3% potassium perchlorate, 19.5% phenolic resin, 8% nitrocellulose , 0.5% stearate. Wherein, the particle size of the powder is 10 μm.

Embodiment 2

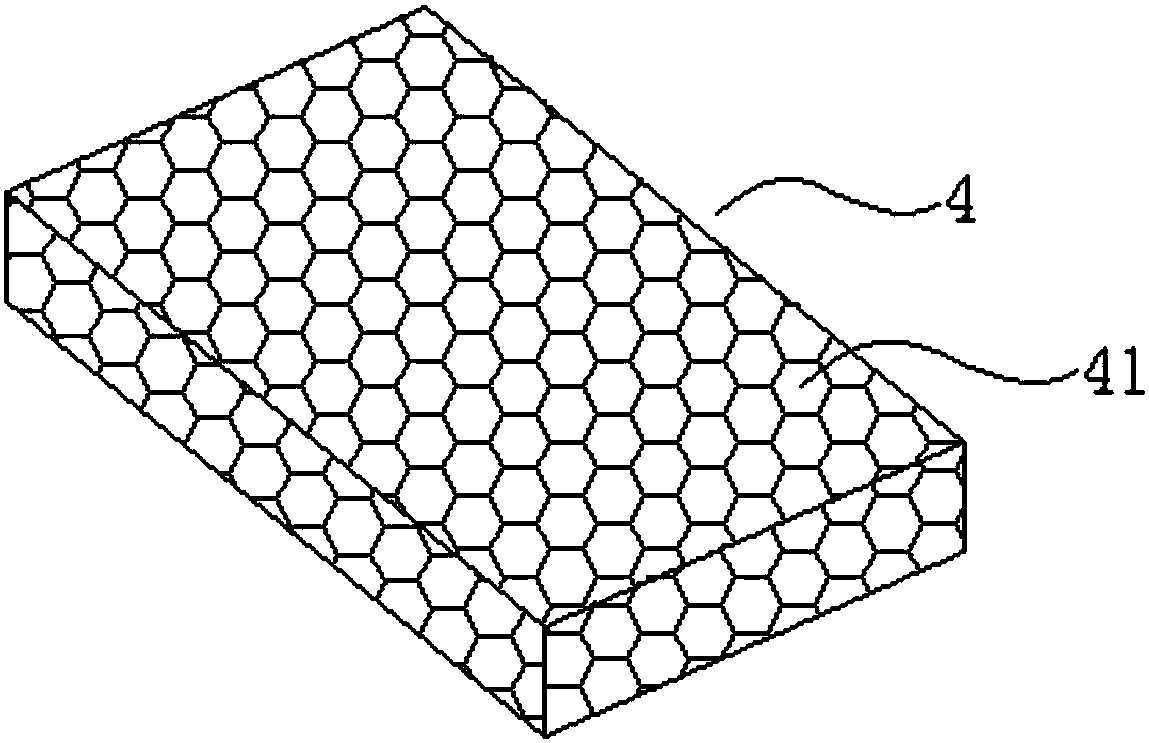

[0024] A kind of flame-retardant material of the present invention, its graphite sheet 1, copper mesh 2, adhesive layer 5 are arranged identically with embodiment 1. The difference is that if figure 2 As shown, the fireproof base layer 4 is provided with a honeycomb grid consistent with the shape of the copper mesh 2, and an accommodation chamber 41 is formed between the grids, and the accommodation chamber 41 is used to accommodate powdery composite flame retardants. The accommodation cavity 41 forms the composite flame retardant layer 3 . Wherein, the composite flame retardant is configured in the same manner as in Example 1.

[0025] The working principle of the flame retardant material of the present invention is as follows: the flame retardant material of the present invention can be directly used as a flame retardant board, or the flame retardant material of the present invention can be adhered to an existing board to realize flame retardancy of the existing board per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com