Oil product sequence conveying system and method

A technology for conveying systems and oil products, applied in pipeline systems, chemical instruments and methods, cleaning methods and appliances, etc., can solve problems such as oil product mixing, achieve the effects of reducing mixing, avoiding mixing, and reducing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

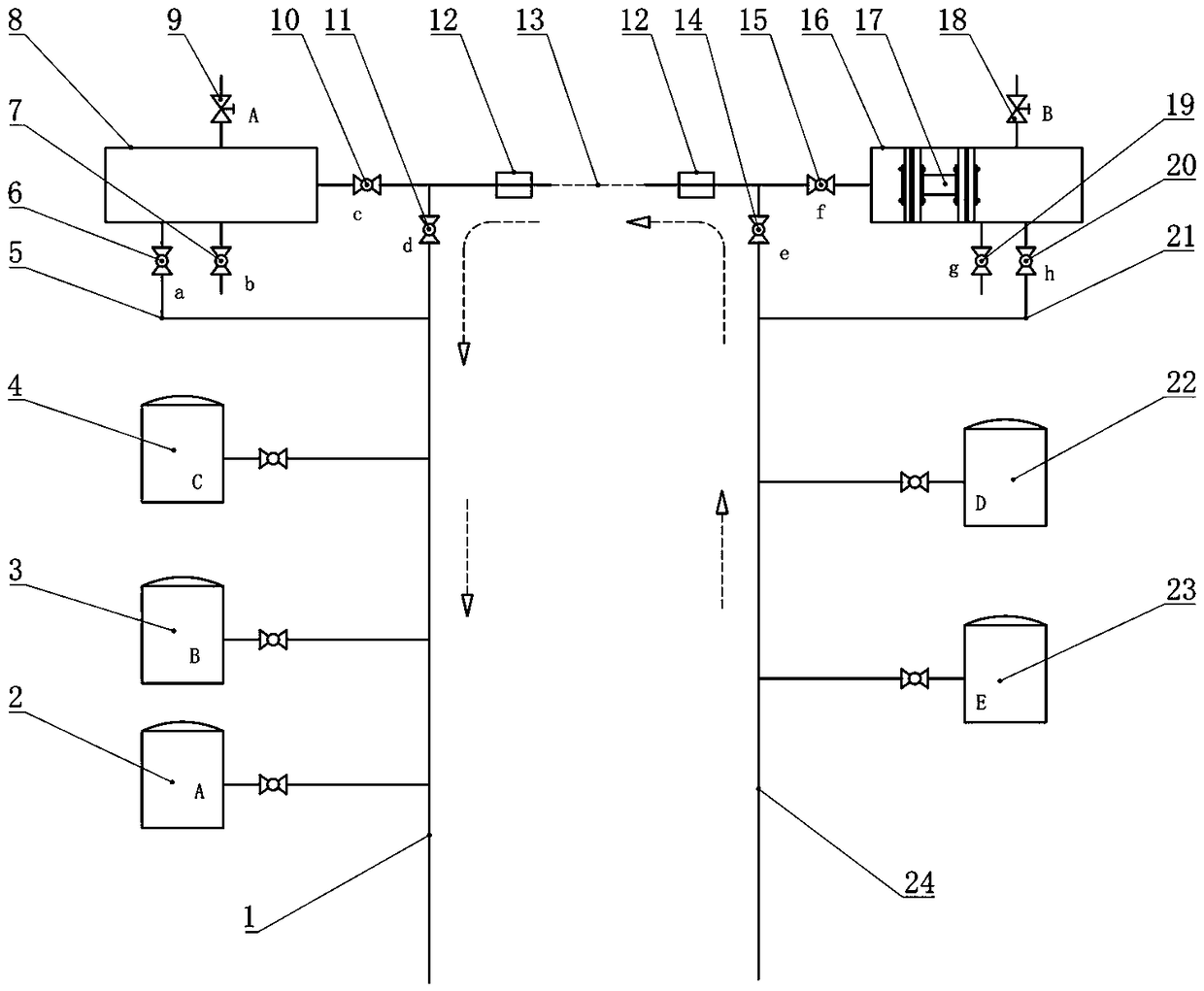

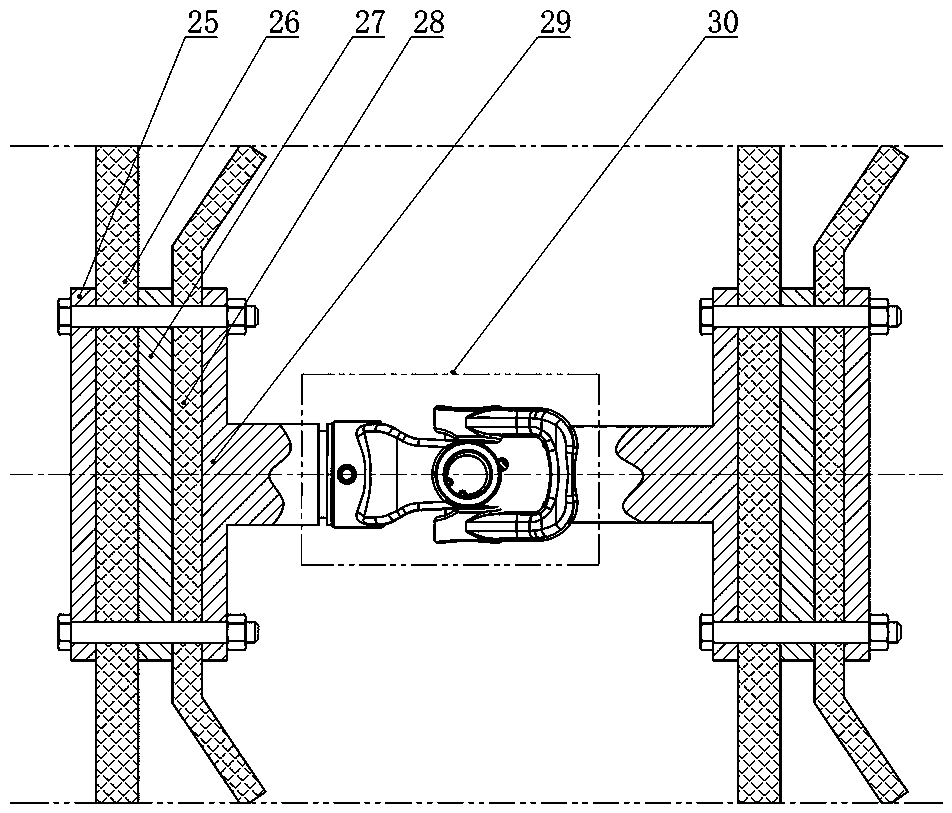

[0036] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 and figure 2 The present invention is described below. The positional relationship of up, down, left and right is based on the attached figure 1 determined by the layout direction.

[0037] An oil sequential delivery system mainly includes a ball receiving barrel 8, a ball sending barrel 16, a main pipeline 13, an oil outlet pipeline 24, an oil return pipeline 1 and a pig 17.

[0038] The oil outlet pipeline 24 is connected to the main pipeline 13 , and the oil outlet pipeline 24 is provided with a ball valve e 14 near the main pipeline 13 . The storage tank D22 and the storage tank E 23 are connected to the oil outlet pipeline 24 , and the oil outlet pipeline 24 can also be connected to other pipelines or storage tanks for deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com