Analysis method of phosphorus content in phosphoric pig iron

A technology of phosphorus content and pig iron, applied in the direction of electrical excitation analysis, thermal excitation analysis, material excitation analysis, etc., can solve the problems of long time-consuming detection method and large error of detection results, shorten detection time, increase strength and avoid loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1~embodiment 3 is the embodiment that makes working curve, and only the size of calibration sample is different in embodiment 1, embodiment 2 and embodiment 3, all the other features are the same;

[0055] Example 1

[0056] Take the pig iron from the previous batch, and select a small block with an analysis surface area of 30mm×30mm and a height of 30 mm on the pig iron as a calibration sample. The analysis surface of the calibration sample has no shrinkage cavity, no inclusions, and no cracks, and then the analysis surface Polish with a 40-grit disc emery cloth;

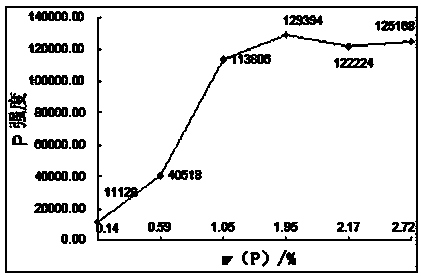

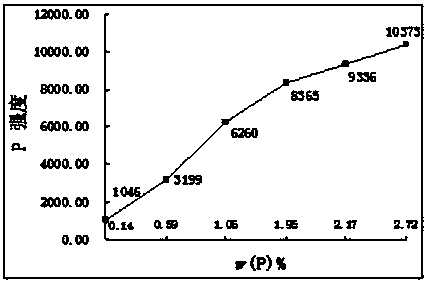

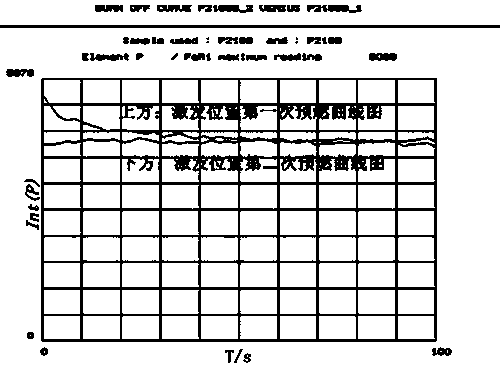

[0057] The standard sample was determined by ICP spectrometry, and then measured by the spark source atomic emission spectrometer according to the above-mentioned working parameters, and the interference of the element on the phosphorus content was corrected according to formula 1, and the correction coefficient KCr=-0.618 was obtained, and after regression Obtain the working curve of phosphoru...

Embodiment 2

[0059] The analytical surface area of the calibration sample in Example 2 is 30 mm×45 mm, and the height is 50 mm; other features are the same as in Example 1.

Embodiment 3

[0061] The analysis surface area of the calibration sample in Example 3 is 50 mm×50 mm, and the height is 10 mm; other features are the same as in Example 1.

[0062] What needs to be explained is that once the working curve is made, it can be used for a long time without requiring a working curve for each detection of the sample to be tested, and it is not necessary to process the calibration sample for each detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com