Automatic honeycomb sheet weight and thickness measuring method

An automatic measurement, honeycomb sheet technology, applied in the field of composite materials, can solve the problems of inability to meet the evaluation requirements of aviation honeycomb sheet thickness and density accuracy, poor repeatability, and large influence, to meet inspection requirements, simple operation, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

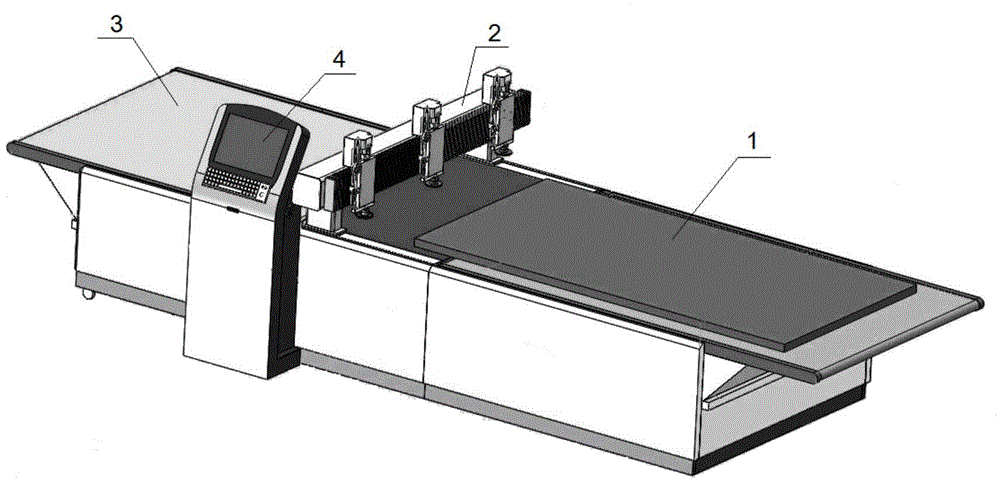

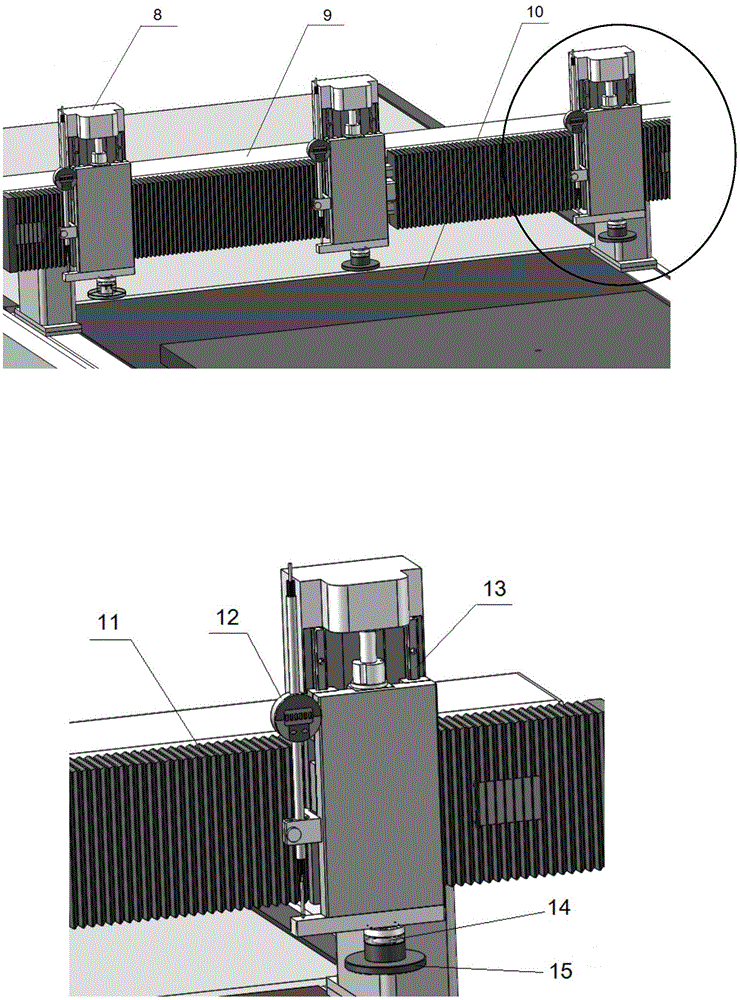

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. refer to figure 1 , figure 2 , image 3 , The automatic method for measuring the weight and thickness of a large honeycomb sheet disclosed in the present invention includes an automatic thickness measurement and weighing instrument composed of a weighing unit 1, a thickness measuring unit 2, a material receiving platform 3, and a control system 4.

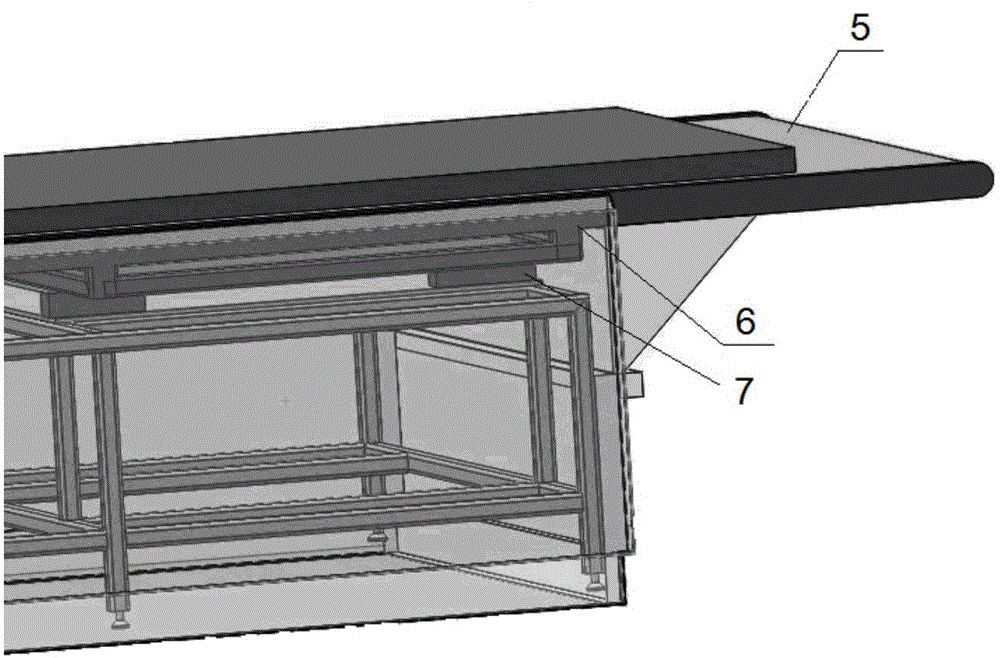

[0028] The weighing unit 1 is used for weighing and measuring the sliced honeycomb sheet, and positioning and conveying the weighed sheet. The weighing unit 1 is composed of a platform 6, a load cell 7, a honeycomb sheet conveying device 5, etc. Composition; the load cell is installed under the table, which is four symmetrical installations. When the honeycomb sheet is placed anywhere on the table, the signal measured by the load cell is fed back to the weighing control system, and the system displays the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com