DIP16 multichip packaging special lead frame and packaging method thereof

A multi-chip packaging, special-shaped lead technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of single structure and large upper board area, so as to reduce the damage to the device, reduce the area, and improve the working stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

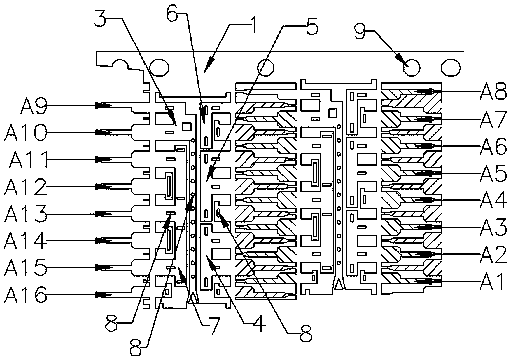

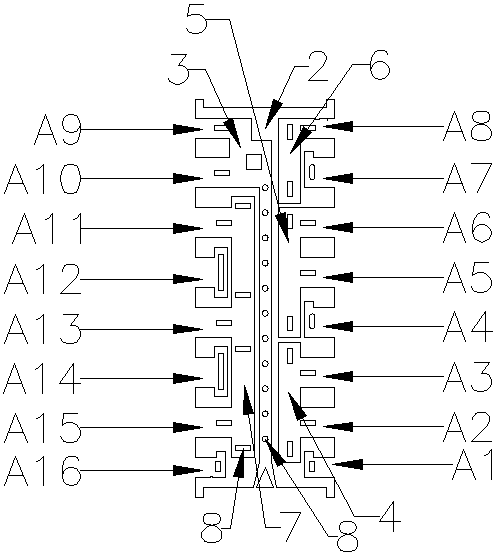

[0032] This embodiment, as a preferred embodiment of the present invention, discloses a DIP16 multi-chip packaging special-shaped lead frame, and its specific structure is as follows: figure 1 As shown, it includes a lead frame body, and a plurality of frame units are arranged in the lead frame body, the first to eighth pins are arranged on one side of the frame unit in turn, and the ninth pins are arranged in turn on the other side of the frame unit. To the sixteenth pin, a long base island is provided in the middle of the frame unit, and a circular locking glue hole is provided on the long base island; one end of the long base island is connected to the ninth and tenth pins; the The first to third base islands are arranged on the side of the long base island close to the first to eighth pins; the first base island is connected to the second and third pins, and the second base island is connected to the fifth and third pins. The six pins are connected, the third base island i...

Embodiment 2

[0035] According to a kind of DIP16 multi-chip packaging special-shaped lead frame described in embodiment 1, the present invention also provides the packaging method of this lead frame, comprises the following steps:

[0036] A. First paste 3 MOS chips numbered a, b, and c with the same structure on the fourth base island, and then paste the chips on the first, second and third base islands in sequence. The chip numbers are f in turn , e, d, after the pasting is completed, send it to the oven for pre-curing baking. The pre-curing baking is at a constant temperature of 170°C, and a protective nitrogen gas is introduced. The nitrogen flow rate is greater than 40L / MIN, and the baking time is 1 hour;

[0037]B. First connect the S poles of chips a, b, and c to the first base island, the second base island, and the third base island respectively through wires; then connect the S poles of chips d, e, and f to the Connect the long base island; then connect the G pole of chip a to th...

Embodiment 3

[0046] According to a kind of DIP16 multi-chip packaging special-shaped lead frame described in embodiment 1, the present invention also provides the packaging method of this lead frame, comprises the following steps:

[0047] A. First paste 3 MOS chips numbered a, b, and c with the same structure on the fourth base island, and then paste the chips on the first, second and third base islands in sequence. The chip numbers are f in turn , e, d, after the paste is completed, send it to the oven for pre-curing baking. The pre-curing baking is at a constant temperature of 175°C, and the protective nitrogen gas is introduced. The nitrogen flow rate is greater than 40L / MIN, and the baking time is 1 hour;

[0048] B. First connect the S poles of chips a, b, and c to the first base island, the second base island, and the third base island respectively through wires; then connect the S poles of chips d, e, and f to the Connect the long base island; then connect the G pole of chip a to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com