Secondary battery charging method

A charging method and secondary battery technology, which are applied in the direction of secondary battery charging/discharging, secondary battery, and secondary battery repair/maintenance, etc. problems, to improve battery performance and user experience, increase charging speed, and slow down temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

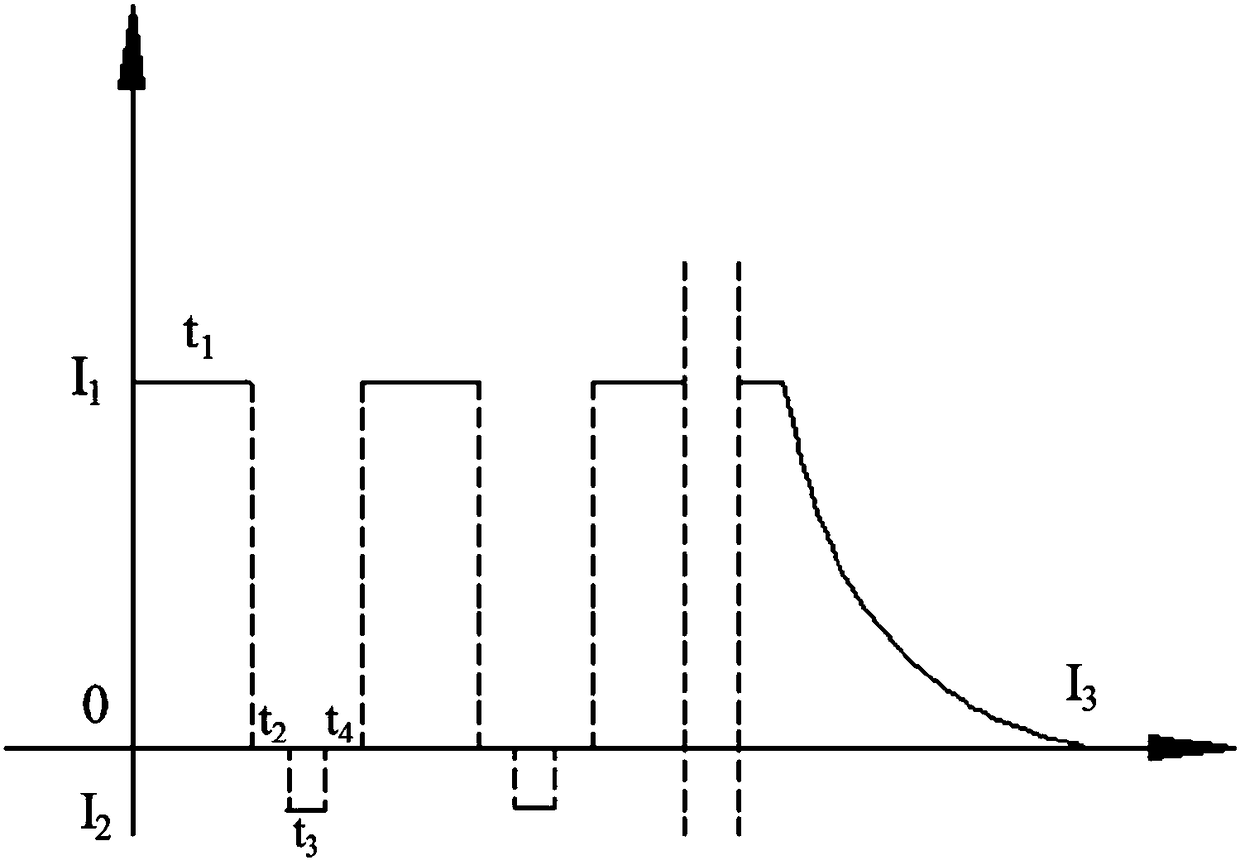

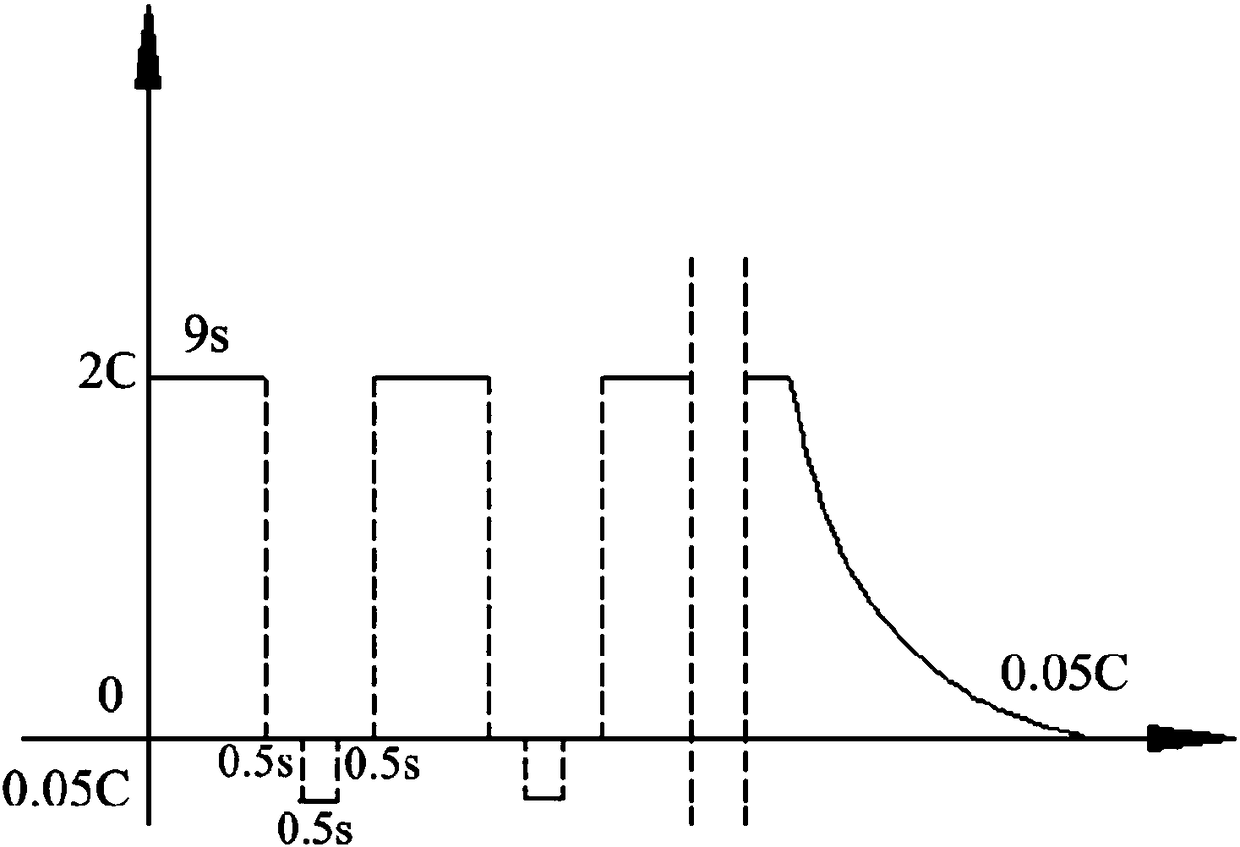

[0046] see figure 2 , in an environment of 25°C, use the secondary battery charging method of the present invention to charge the above-mentioned battery, the specific steps are as follows:

[0047] 1) Charge the battery with a constant current of 2C, and the charging time is 9s;

[0048] 2) Stop charging and let the battery stand still for 0.5s;

[0049] 3) Discharge the battery with a constant current of 0.05C, and the discharge time is 0.5s;

[0050] 4) Stop discharging and let the battery stand for 0.5s;

[0051] 5) Repeat steps 1) to 4) until the battery voltage reaches 4.35V;

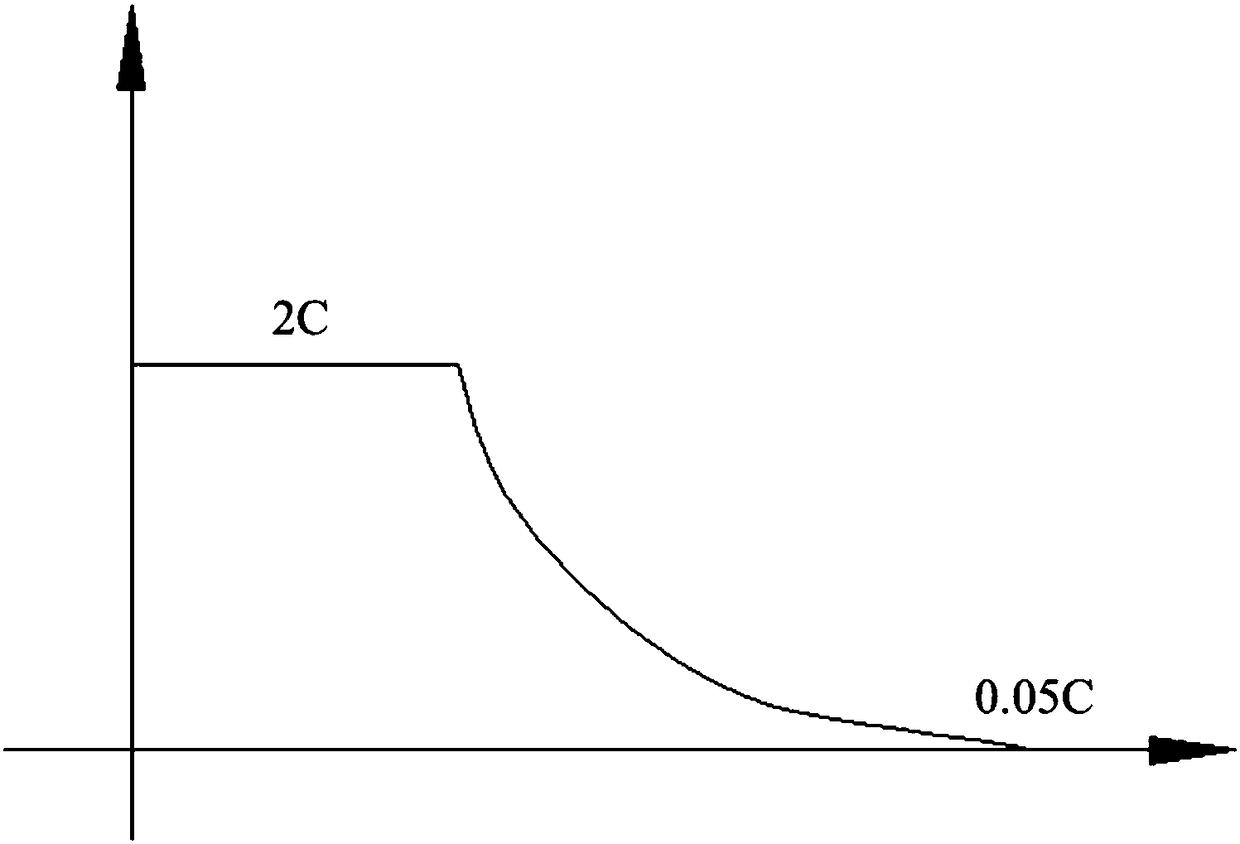

[0052] 6) Charge the battery with a constant voltage of 4.35V until the battery current reaches 0.05C.

[0053] The steps of Examples 2-11 are basically the same as those of Example 1, the only difference is the relevant parameters, and the specific parameters of each example are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com