Energization control method and system of battery cabinet

A battery cabinet and electrical control technology, applied in the field of lithium-ion batteries, can solve the problems of long power-on time, increased maintenance costs, and low power-on efficiency, and achieve the goals of shortening power-on time, increasing hardware costs, and improving power-on efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

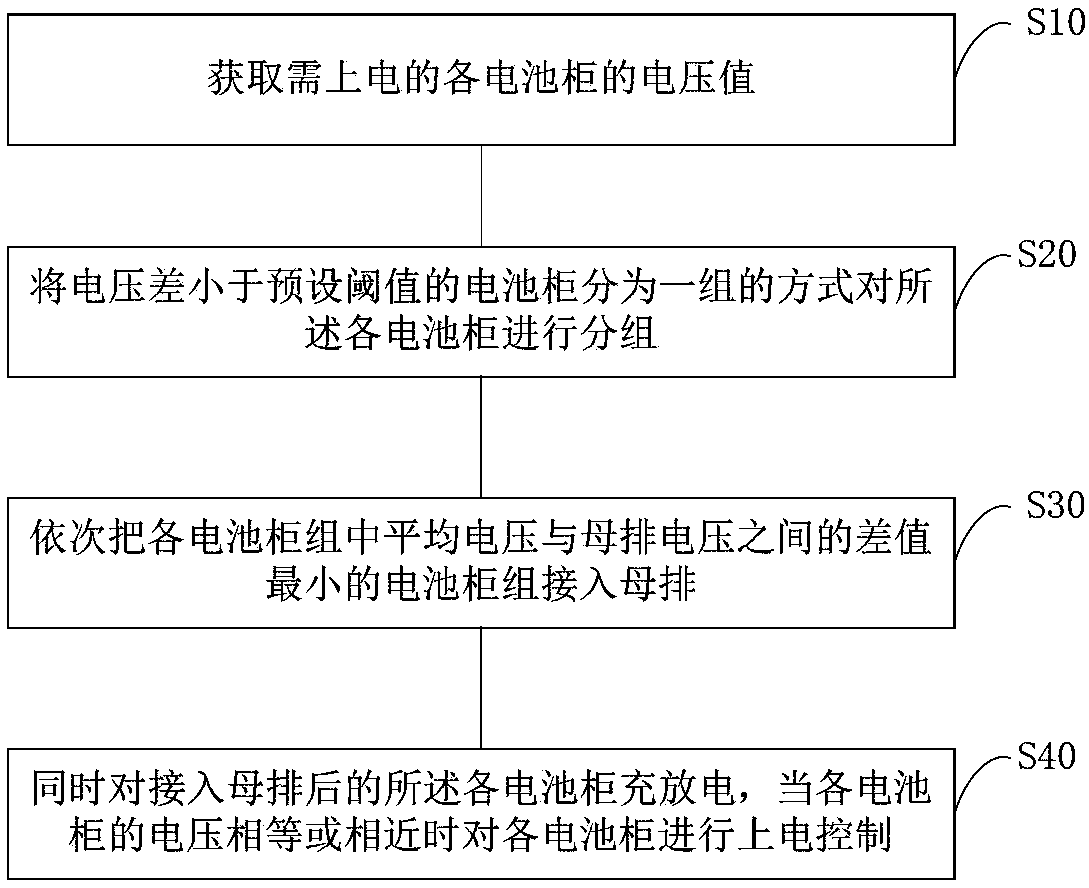

[0038] Specific embodiment 1, please refer to Figure 5 The power-on control method of the battery cabinet provided in this embodiment includes the following steps.

[0039] S11. Sort the average voltage value of each battery cabinet group that is not connected to the busbar from low to high;

[0040] S21. According to the sorting result, connect the battery cabinet group with the lowest average voltage value to the busbar for charging;

[0041] S31. When the voltage value of the busbar rises to the average voltage value of the second-lowest battery cabinet group, connect the second-highest battery cabinet group to the busbar for charging;

[0042] S41, and so on, until all battery cabinets are connected to the busbar for charging.

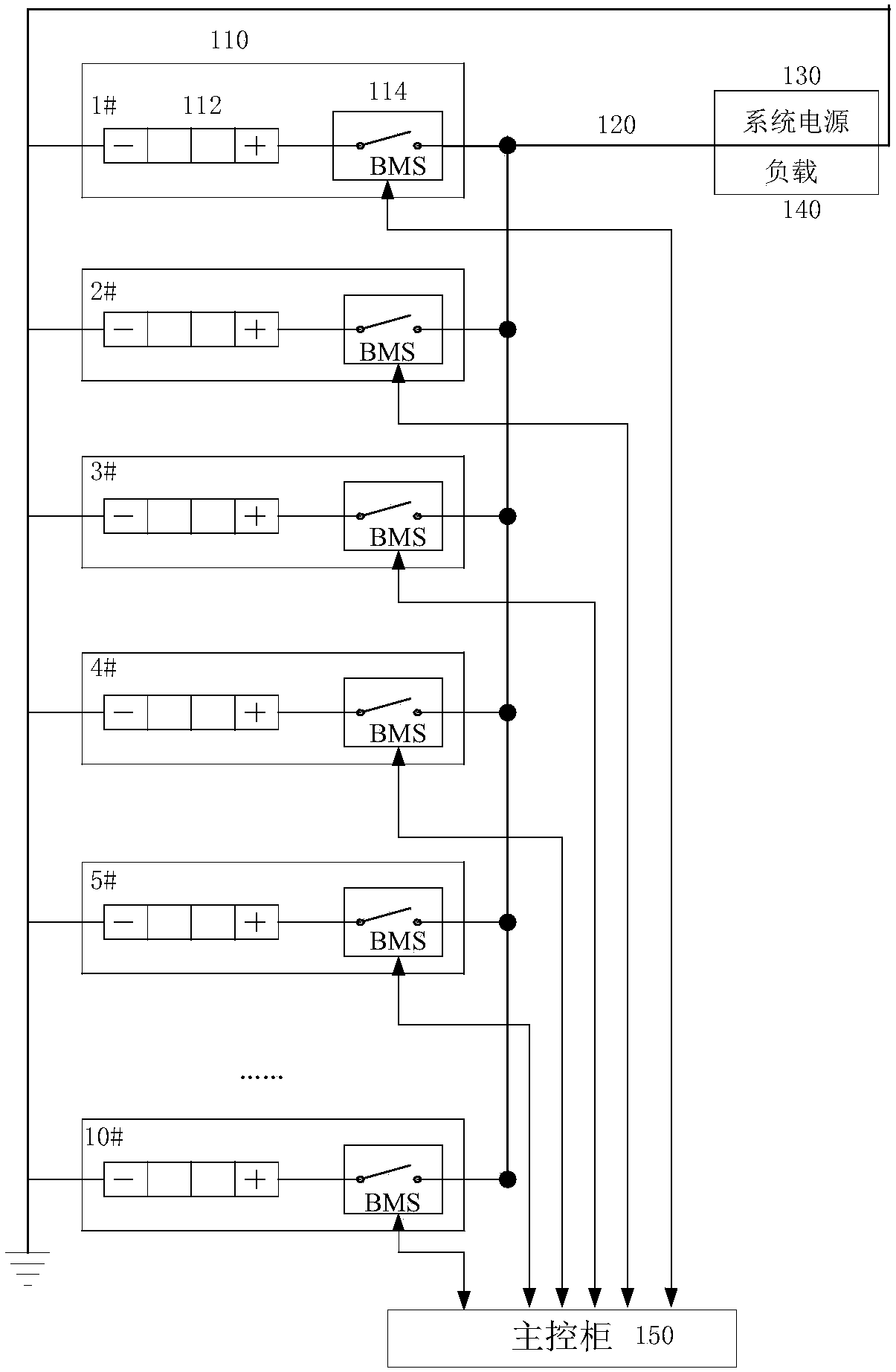

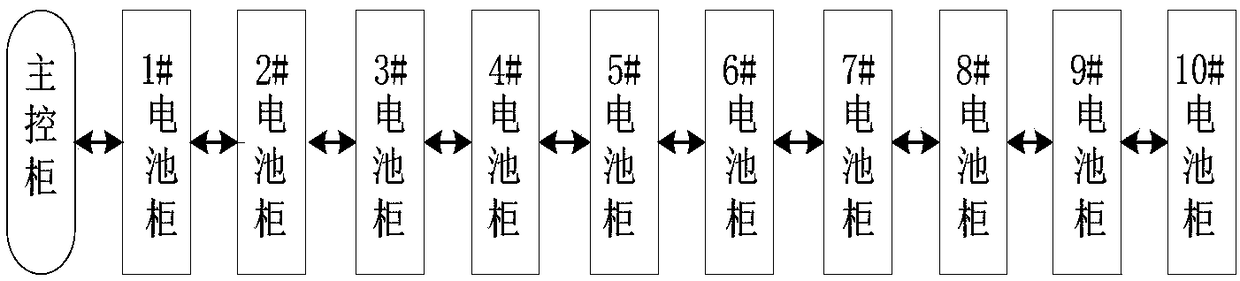

[0043] Combine Figure 2 to 4 The system structure shown is explained. When the system is initially powered on, the system power supply 130 works, and all the relays 116 of the battery cabinet 110 are disconnected, so that the battery cabinet 110 and the b...

specific Embodiment 2

[0047] Specific embodiment 2, please refer to Image 6 The power-on control method of the battery cabinet provided in this embodiment includes the following steps.

[0048] S12. Sort the average voltage value of each battery cabinet group not connected to the busbar from low to high into the first, second to nth battery cabinet group, where n is an integer greater than 2;

[0049] S22. Send a power-on command to the battery cabinet controllers of each battery cabinet in the first battery cabinet group, and each battery cabinet controller closes the corresponding relay after receiving the power-on command to complete the connection of the first battery cabinet group. Charging into the busbar;

[0050] S32. Send a conditional power-on command to the battery cabinet controller of each battery cabinet in the second battery cabinet group. After receiving the power-on command, the battery cabinet controller determines the second battery cabinet according to the conditional power-on command...

specific Embodiment 3

[0053] Specific Example 3, please refer to Figure 7 The power-on control method of the battery cabinet provided in this embodiment includes the following steps.

[0054] S13. Sort the average voltage value of each battery cabinet group that is not connected to the busbar from high to low;

[0055] S23. According to the sorting result, connect the battery cabinet group with the highest average voltage to the busbar for discharge;

[0056] S33. When the voltage value of the busbar drops to the average voltage value of the second highest battery cabinet group, connect the second highest battery cabinet group to the busbar for discharge;

[0057] S43, and so on, until all battery cabinets are connected to the busbar.

[0058] The discharging and voltage equalization and parallel connection mode of this embodiment is basically the same as the charging and voltage equalization and parallel mode of the specific embodiment 1. Combine Figure 2 to 4 The system structure shown is explained. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com