Switched reluctance motor with low ripple torque

A technology of pulsating torque and switched reluctance, which is applied in the field of motors, can solve the problems of large torque pulsation and restrictions on promotion and use, and achieve the effects of reducing torque pulsation, low dependence, and reducing pulsating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

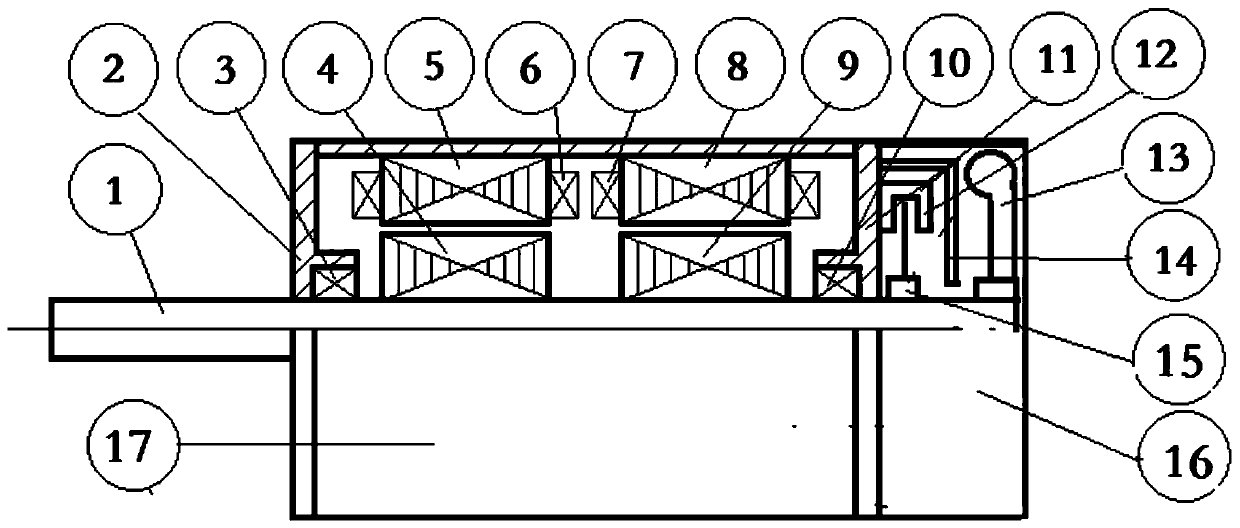

Embodiment 1

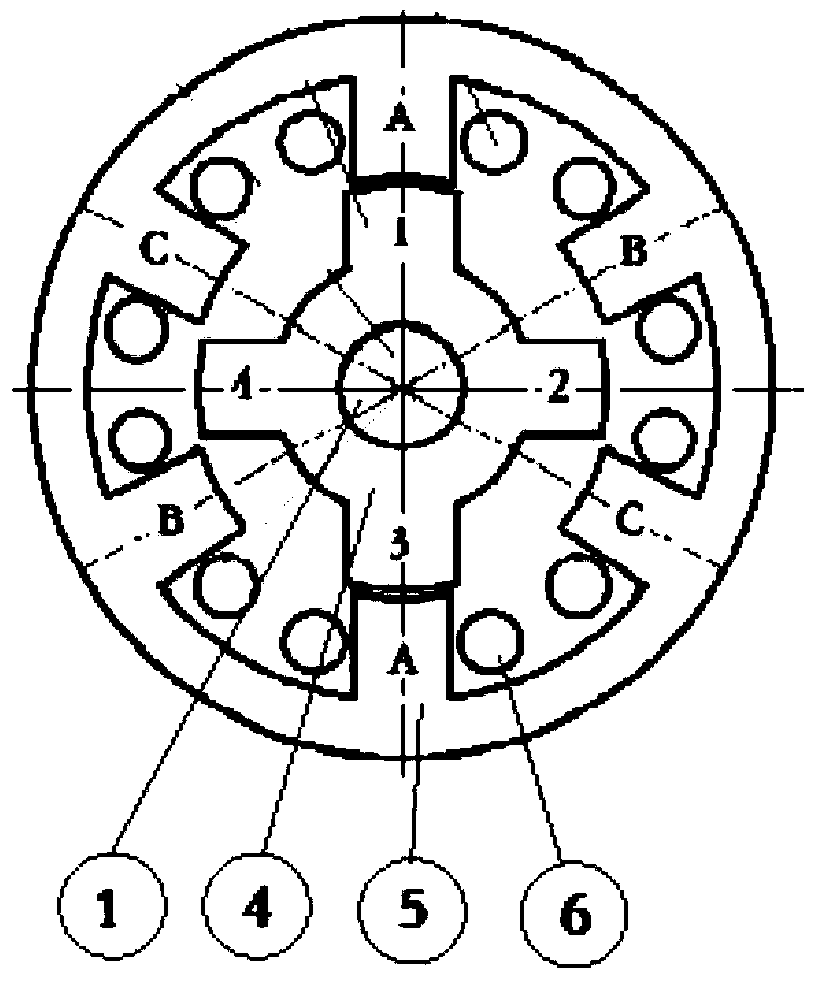

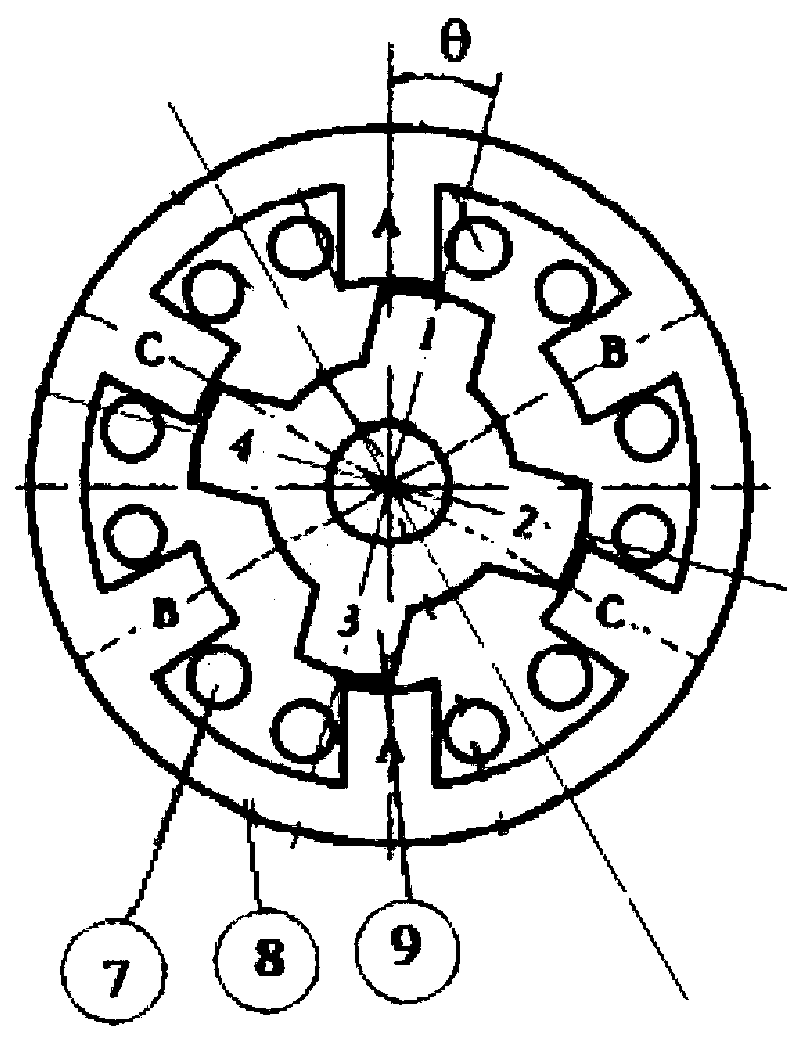

[0032] Projections of the first stator core 5 and the second stator core 8 on a plane perpendicular to the axis of the rotating shaft 1 completely coincide. The first rotor core 4 and the second rotor core 9 are arranged at an angle θ staggered along the circumferential direction of the rotating shaft 1 .

[0033]

[0034] The reason why the first rotor core 4 and the second rotor core 9 are staggered by the angle θ along the circumferential direction of the rotating shaft 1 is as follows:

[0035] The pulsating torque wave generated by the switched reluctance motor is similar to a sine wave, and every time the switched reluctance motor rotates a step angle, a period of pulsating torque wave will be generated at the same time. That is, the cycle of the pulsating torque of the switched reluctance motor is equal to the time period for the switched reluctance motor to rotate a step angle. The control period of the switched reluctance motor with the number of rotor iron core t...

Embodiment 2

[0038] The projections of the first rotor core 4 and the second rotor core 9 on a plane perpendicular to the axis of the rotating shaft 1 completely coincide. The first stator core 5 and the second stator core 8 are arranged at an angle θ staggered along the circumferential direction of the rotating shaft 1 .

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com