Stamping workshop data acquisition system based on embedded Linux

A data acquisition system, stamping workshop technology, applied in transmission systems, general control systems, control/regulation systems, etc., can solve the problems of information islands, difficult on-site extension of business planning processes, and restricting the general application of MES, and achieves the goal of solving bottlenecks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The production process of the stamping workshop is to put a good mold on the stamping machine, drive the flywheel through the motor, and drive the crank linkage mechanism through the clutch and the transmission gear to make the slider move up and down, so that the steel plate is directly subjected to deformation force and deformed in the mold, so as to obtain a certain shape , size and performance of processed parts.

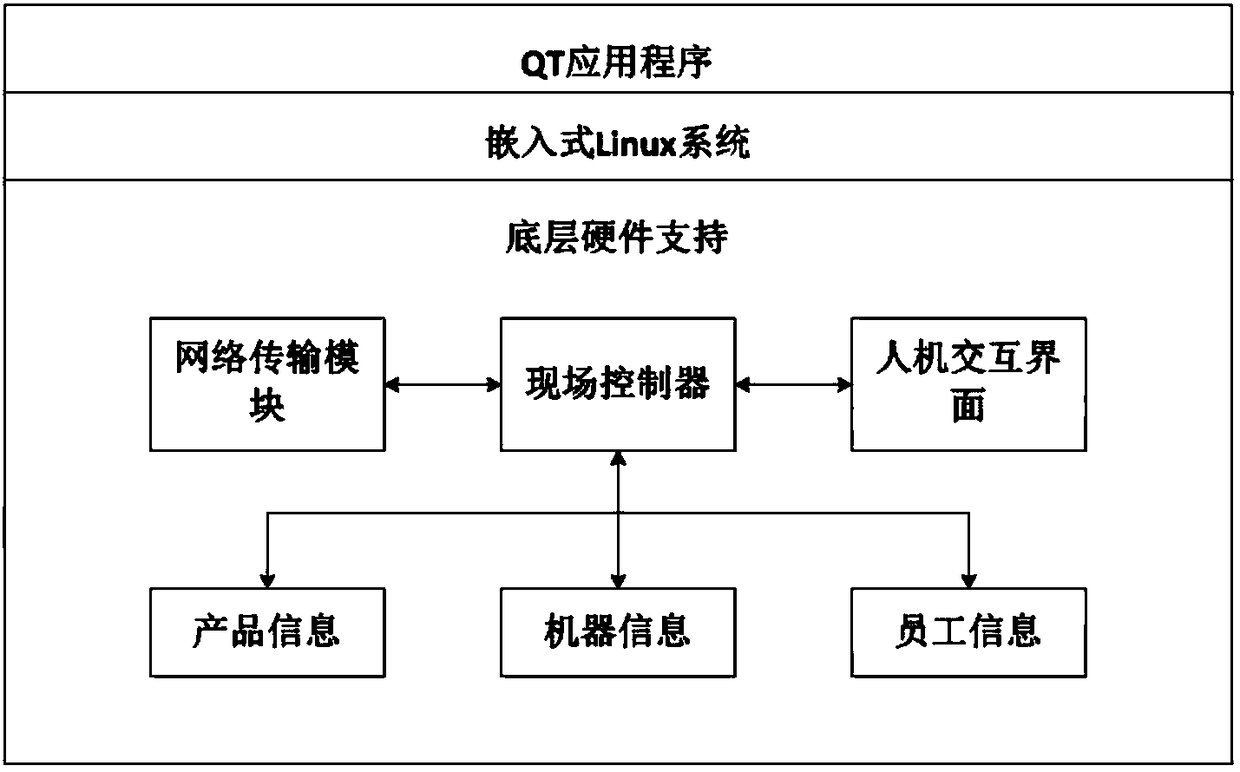

[0016] Such as figure 1 As shown, the production process in the stamping workshop involves all aspects of product production, and whether it is employee information, product information, machine information, product processing progress, or task dispatch, etc., all involve a large amount of data. Faced with such a large amount of production data information, the on-site controller needs to have the function of accurately collecting and uploading production data. The user can clearly and intuitively view the on-site production equipment information through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com