Forming method of narrow intermittent, twisted, multi-blade densely distributed cascade parts

A multi-blade and part technology, which is applied in the directions of casting mold components, foundry workshops, casting molding equipment, etc., can solve the problems of small forming interval, assembly error, and high requirements on shape and position accuracy, improve production efficiency, and reduce the problem of low accuracy. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

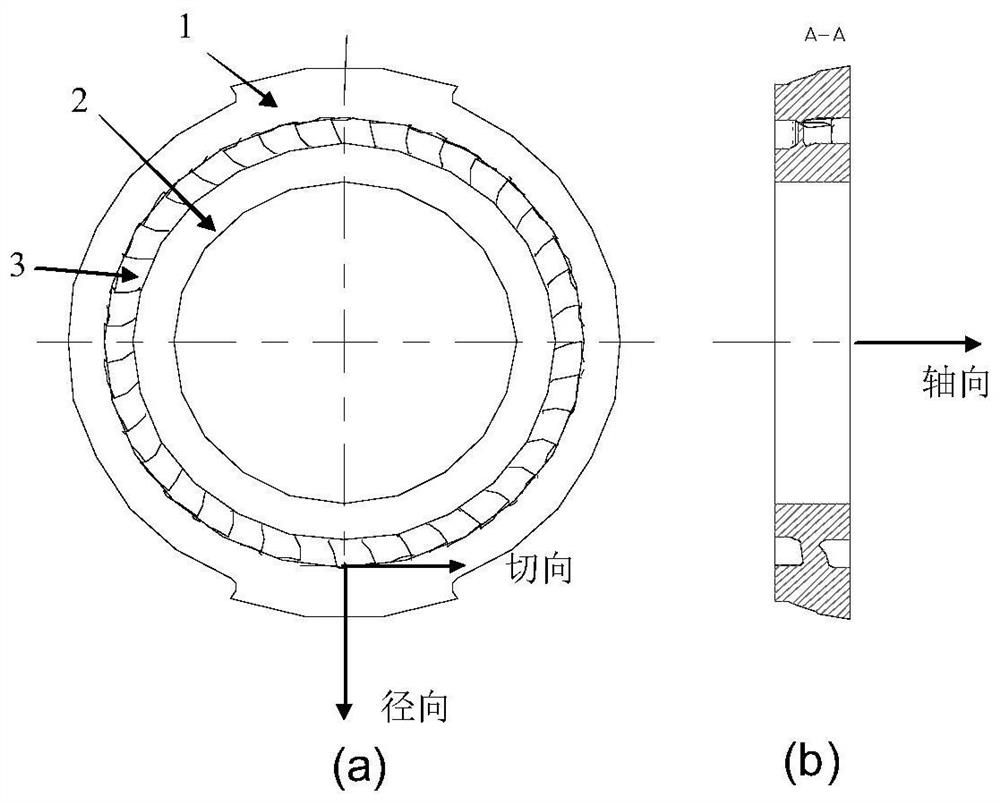

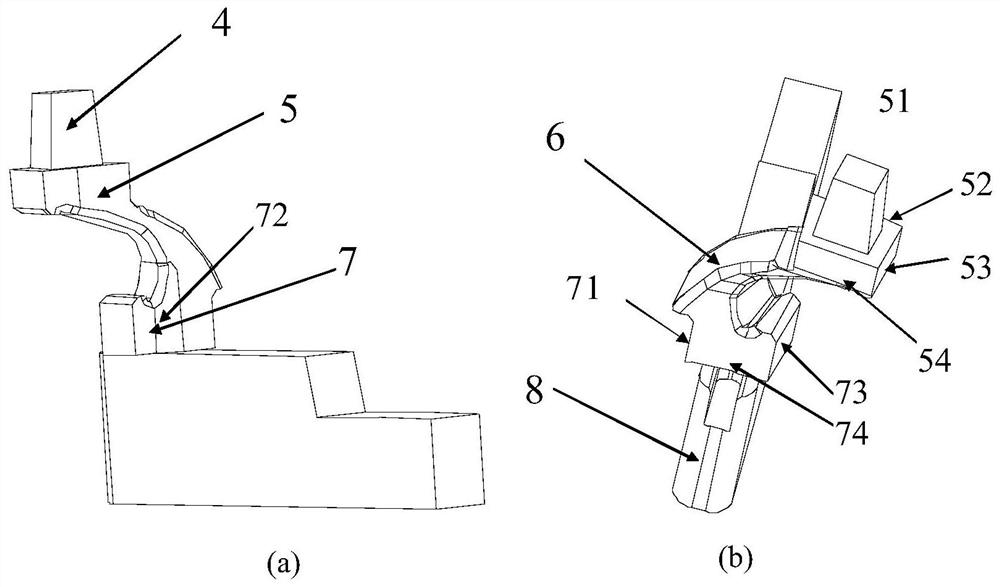

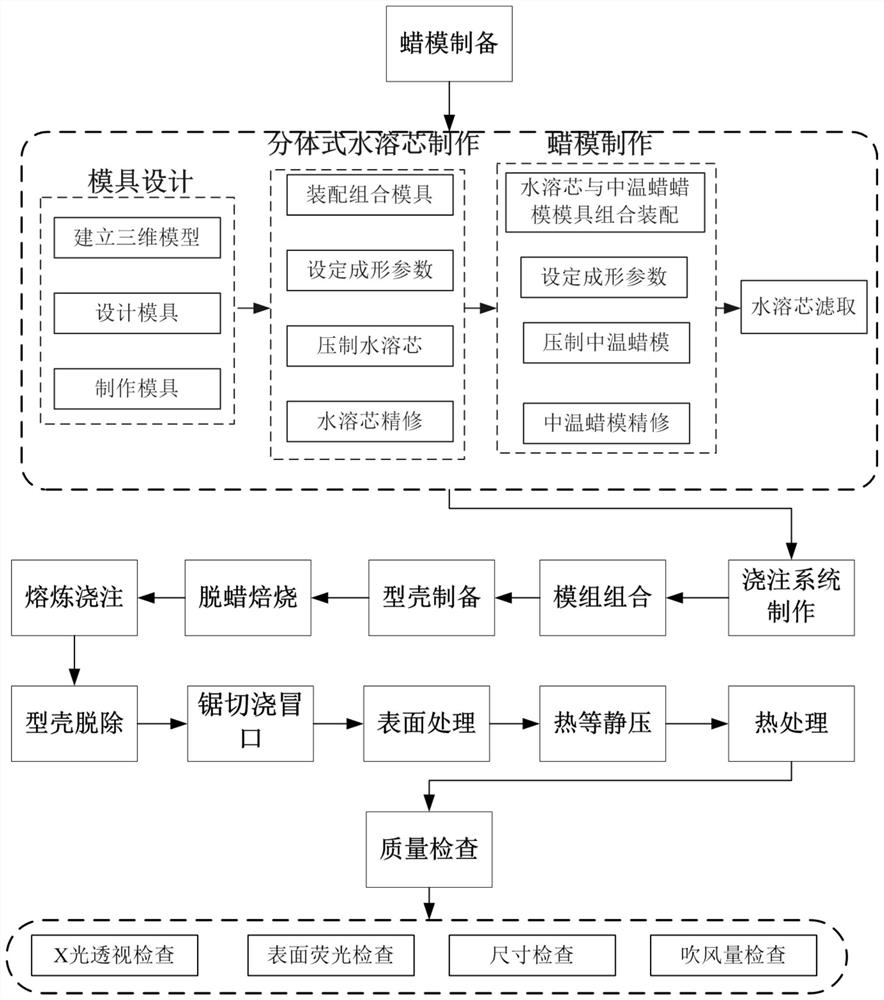

[0093]The invention is further described with reference to the drawings.

[0094]In order to solve the above-mentioned shortcomings of the existing manufacturing techniques, the present invention provides a method of forming a low-cost narrow intermittent, distortion, and multi-blade dense distribution of the leaf grid. The present invention employs the flow channel region between the water-wax-shaped divided shaped blades, and then the accurate combination of each water-core is achieved by the positioning system to ensure the accuracy of the critical flow path region size; the combined water-based core is used as an outer mold. Core ", with completion of wax mold production; use a special solution to filter the water core to obtain a wax mold that is completely consistent with the casting entity. After the casting system, the module combination, the shell preparation, dewaxing, smelt cast, housing removal, sawing, surface treatment, heat, etc., heat treatment, quality inspection, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com