A processing method for melting tc4 alloy in an electron beam cooling hearth furnace and a processing method for a medium-thick slab

A technology of electron beam cooling hearth furnace and processing method, applied in the field of titanium alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to explain the overall concept of the present application more clearly, the following detailed description will be given by way of examples in combination with the accompanying drawings.

[0025] In order to obtain the processing performance of TC4 alloy smelted in electron beam cooling bed EB furnace, the inventor organized a large number of experiments to verify the difference between TC4 alloy melting in electron beam cooling bed EB furnace and general metals through processing experiments of different deformation modes and deformation amounts. Processing law, for general metals, the process determines the microstructure, and the microstructure determines the mechanical properties. However, the results presented in the deformation processing test of the TC4 alloy prepared by the EB furnace are not exactly the same as the law.

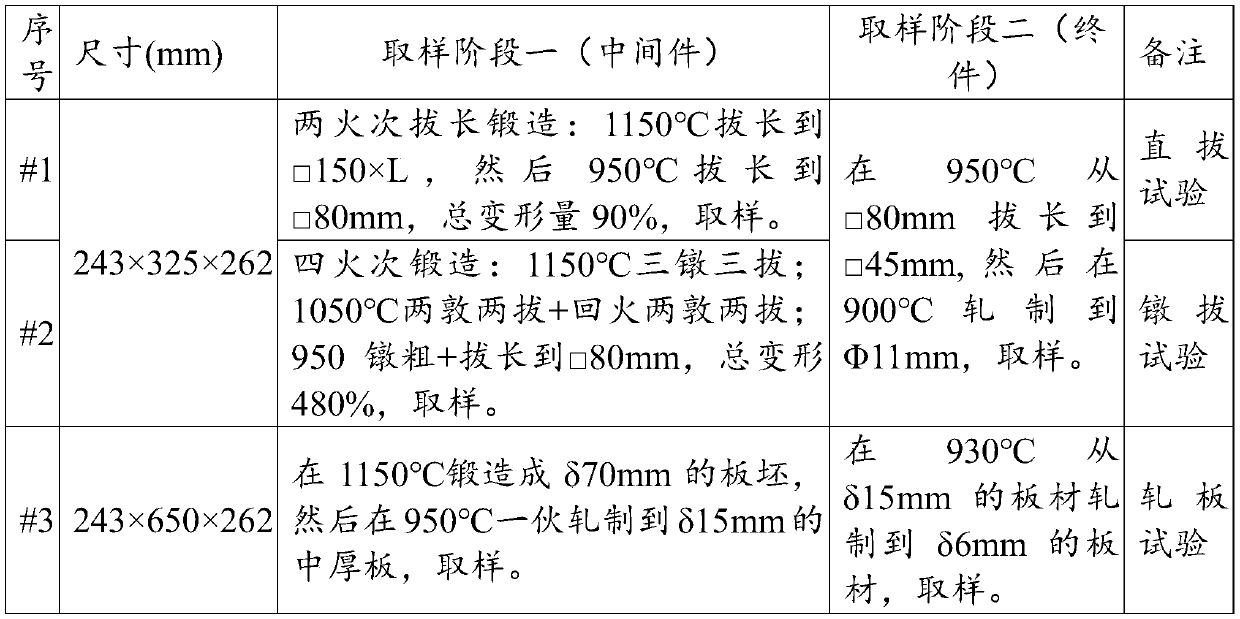

[0026] A detailed discussion will be made below in conjunction with a set of experiments shown in Table 1. The experimental blanks i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com