Dry-mixed mortar production line

A technology of dry powder mortar and production line, which is applied in the direction of batching weighing instrument, mixing plant, and sales of raw material supply devices, etc. It can solve the problems of uneven heating of dry powder mortar performance, large production line area, no energy saving and environmental protection, etc., and achieve airtightness Good, reduce floor area, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

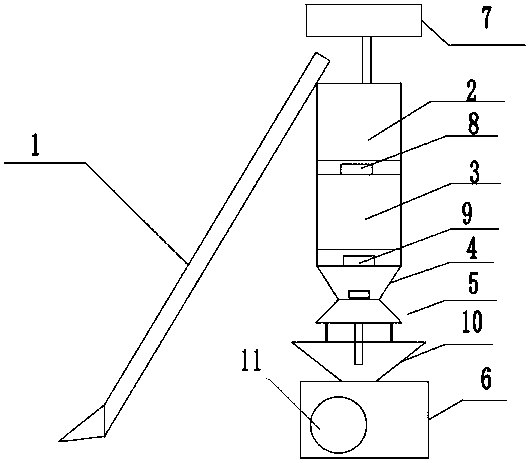

[0015] Example 1, such as figure 1 , a dry powder mortar production line, including a lifting conveyor 1, a crusher 2, a drying device 3, a batching weighing system 4, a premixing device 5, a secondary mixing conveying device 6, and a dust removal device 7, and the lifting conveyor 1 is a spiral Type vertical conveyor, the lifting conveyor 1 sends the material to the entrance of the top of the crusher 2, the dust removal device 7 is set on the top of the crusher 2, the bottom of the crusher 1 is connected with the drying device 3, and the bottom of the drying device 3 is weighed with the ingredients The system 4 is connected, the ingredient weighing system 4 is connected to the premixing device 5, the premixing device 5 is connected to the secondary mixing conveying device 6; the dust removal device 7, the crusher 2, the drying device 3, the ingredient weighing system 4, the premixing The device 5 and the secondary stirring and conveying device 6 are installed sequentially fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com