Paper-tube surface paper pasting machine

A technology of veneer paper and paper tube, which is applied in the direction of cardboard winding articles, etc., can solve problems such as mechanical instability, misalignment of docking positions, and misalignment, and achieve the effect of improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

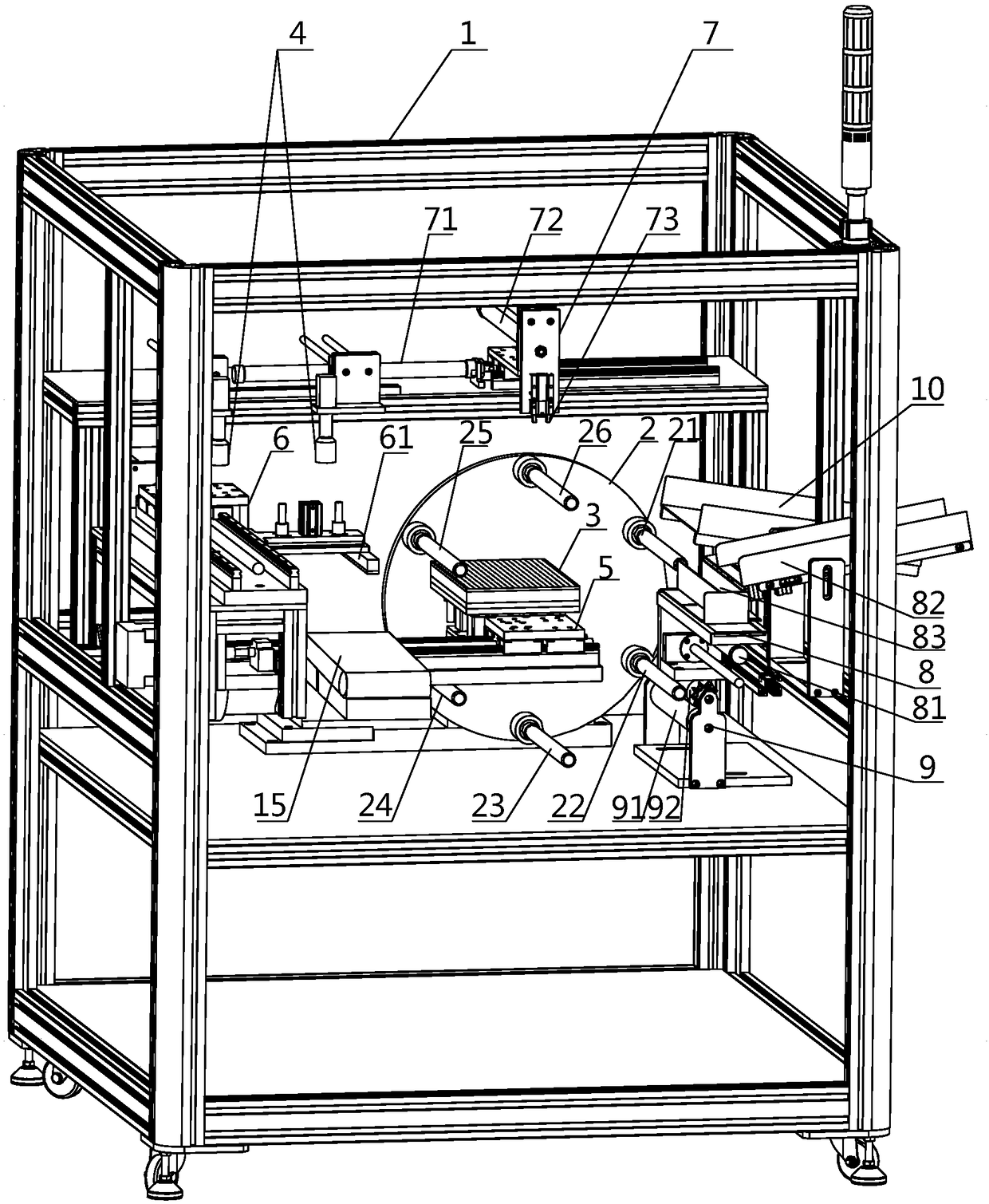

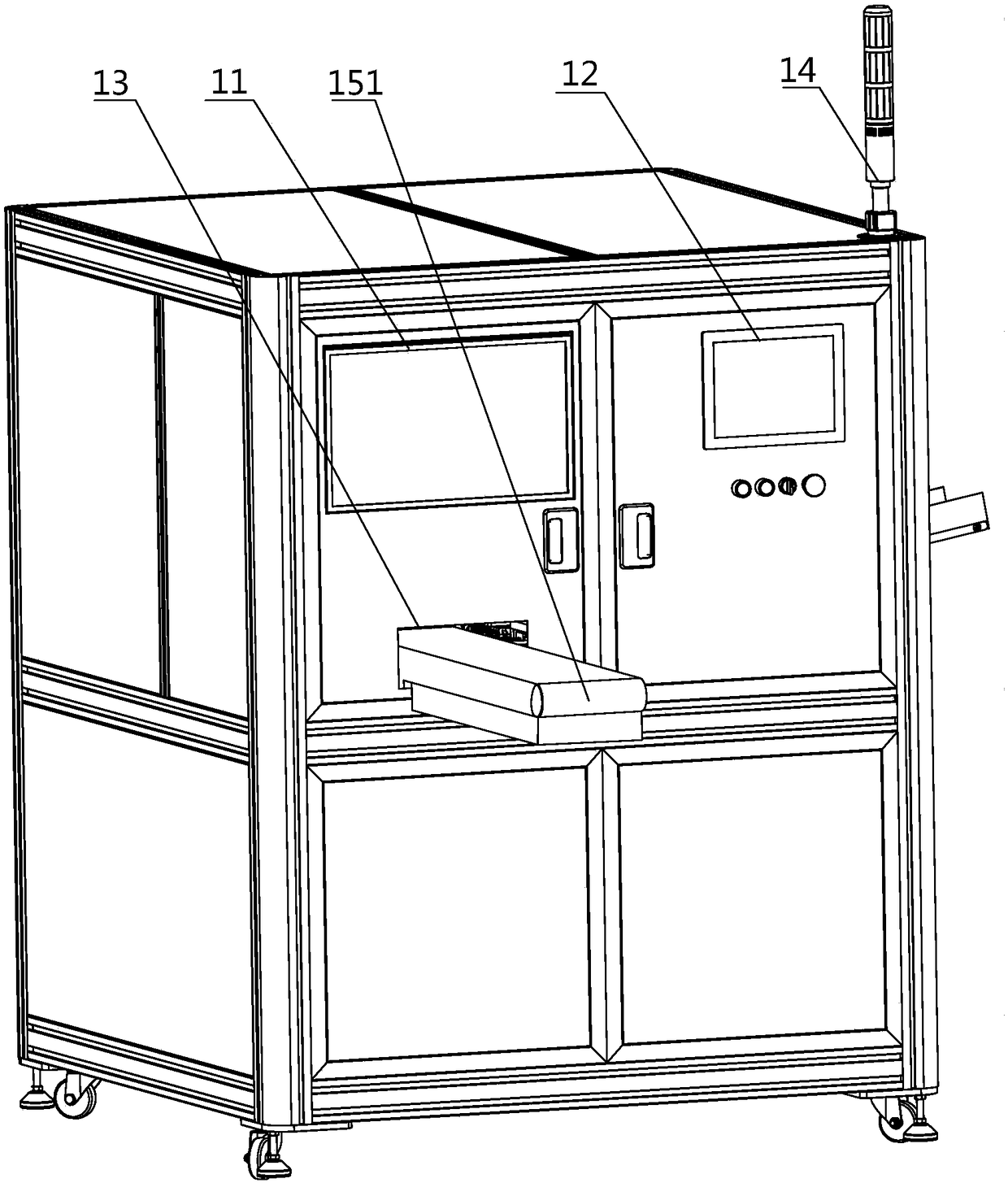

[0047] Such as Figure 1-2 As shown, in the paper tube laminating machine described in Embodiment 1 of the present invention, the purpose of the implemented technical means is to solve the problem that the traditional laminating machine equipment is easy to cause the paper tube part to form overflow glue, paper tube and facial paper. Problems such as low equipment efficiency and poor quality of products produced by equipment due to insufficient matching and easy separation, and inaccurate processing links. The body 1 of the processing mechanism, at the same time, various automation equipment schemes designed in combination with different processing requirements, obviously, a display screen 11 for real-time monitoring and display of equipment status can be configured at an appropriate position on the surface of the body 1, and the operating status of the equipment can be adjusted. Or a touch screen 12 for setting parameters and a warning light 14 for indicating or warning equip...

Embodiment 2

[0070] Such as Figure 1-2 As shown, the paper tube laminating machine described in the second embodiment of the present invention is a deformation based on the technical solution implemented in the first embodiment, and the technical solution after the deformation belongs to the same concept as the first embodiment. In the second embodiment, a six-station turntable with a dial-like structure can be set at the center of the body 1, and the dial-like structure has a number of rotating sticks to match the processing mechanism at the corresponding position;

[0071] According to different processing requirements, a circular tube feeding mechanism 8 as implemented in Embodiment 1 can be set at the two o'clock direction of the dial structure;

[0072]According to different processing requirements, a gluing mechanism 9 as implemented in Embodiment 1 can be set at the four o'clock direction of the dial structure;

[0073] According to different processing requirements, a glue waitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com