Cement-based dry-mixed mortar

A foundation and sand mixing technology, applied in the field of building construction, can solve the problems of building plastering mortar cracking, unstable project quality, and insufficient strength to meet the requirements, and achieve low cost, not easy to shrink and crack, and tensile strength big effect

Inactive Publication Date: 2018-07-10

TIANJIN HONGQUAN CONCRETE MIXING

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the influence of the technical proficiency of the construction personnel and the quality of various raw materials such as cement and sand, the mortar used on the construction site, whether it is masonry mortar, plastering mortar, or ground leveling mortar, often has cracking phenomena in building plastering mortar ( Even if the most traditional clay brick walls are plastered with cement mortar, there will be large-scale cracks), resulting in unstable project quality, insufficient strength, and even poor quality, which has become a common problem in construction quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

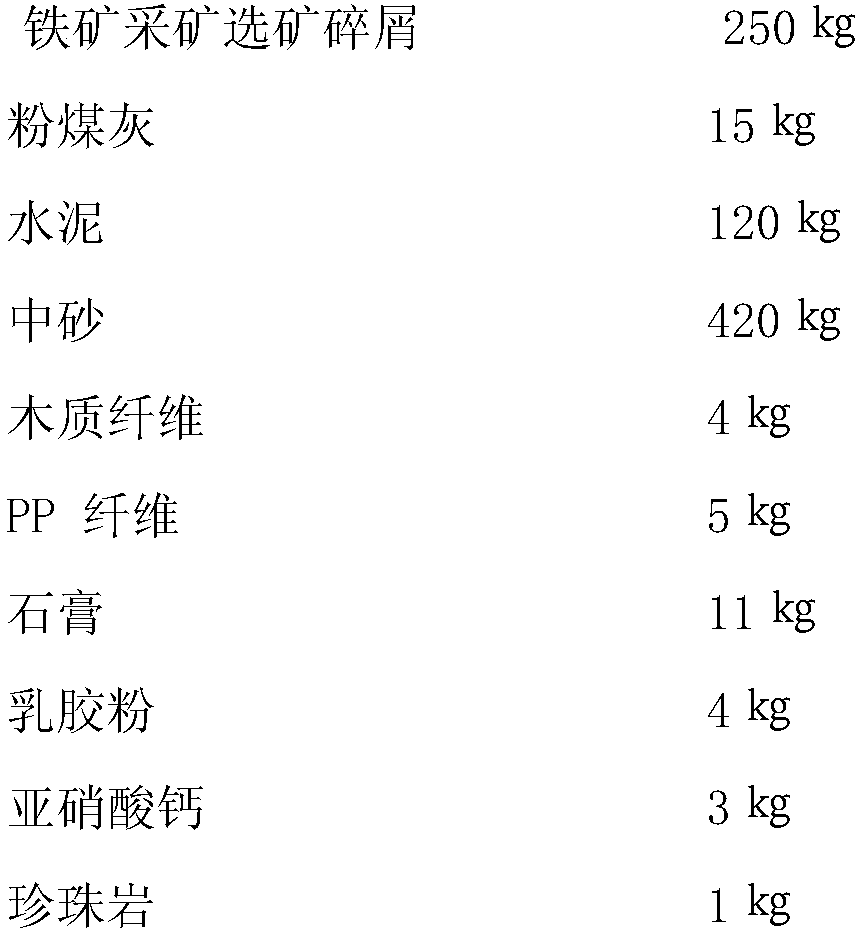

Embodiment 1

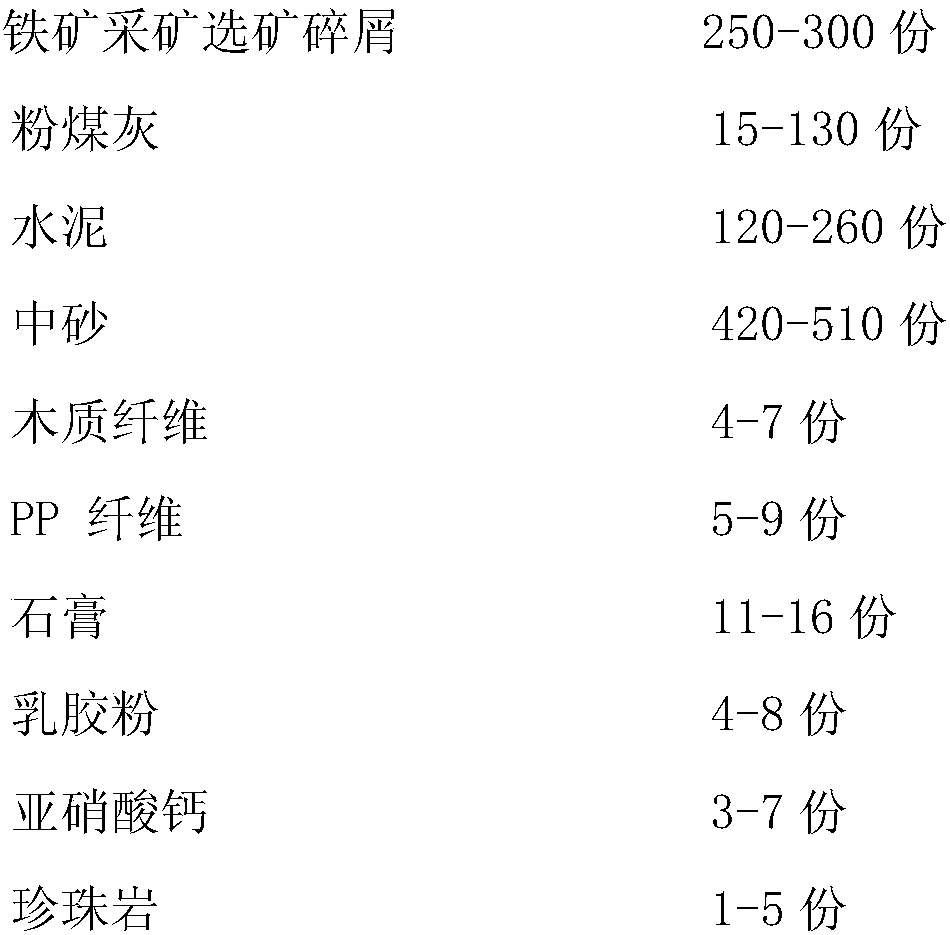

[0013] A kind of cement-based dry-mixed mortar, its component and weight number are:

[0014]

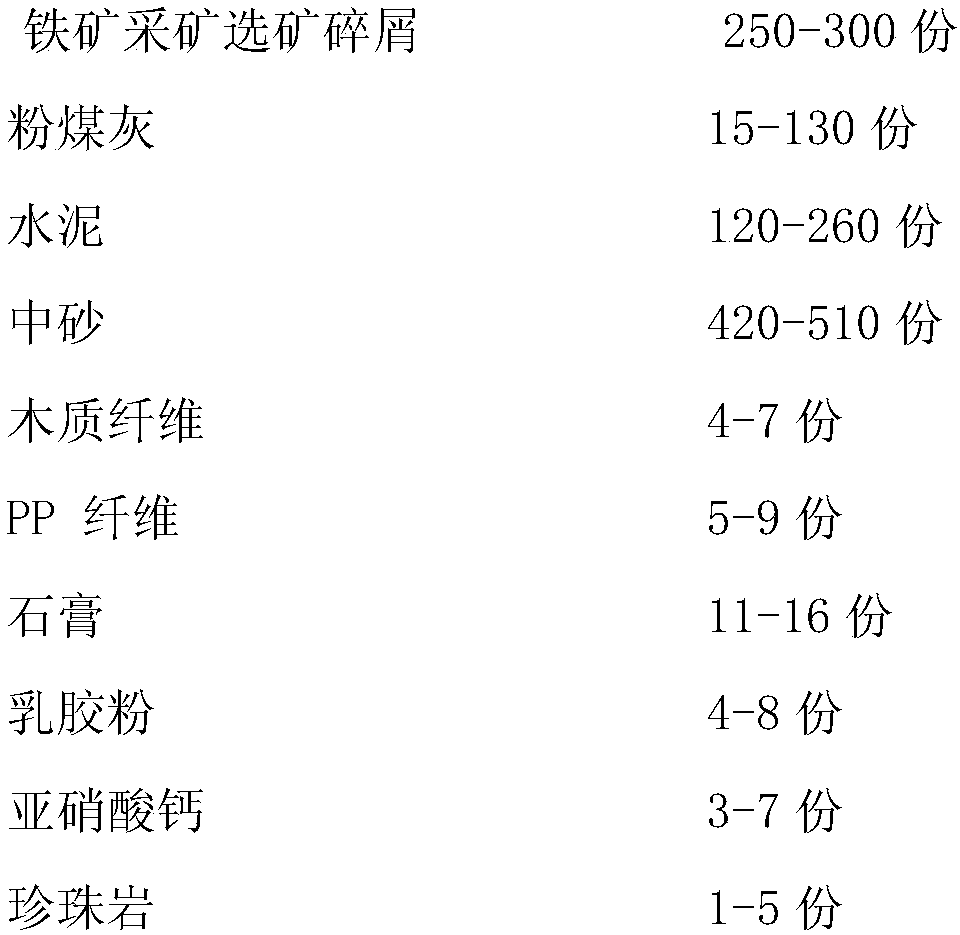

Embodiment 2

[0016] A kind of cement-based dry-mixed mortar, its component and weight number are:

[0017] .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to cement-based dry-mixed mortar. The cement-based dry-mixed mortar is prepared from, by weight, 250-300 parts of iron mine mining and beneficiation scrap, 15-130 parts of coal ash, 120-260 parts of cement, 420-510 parts of medium sand, 4-7 parts of wood fibers, 5-9 parts of PP fibers, 11-16 parts of gypsum, 4-8 parts of latex powder, 3-7 parts of calcium nitrite and 1-5 parts of perlite. The cement-based dry-mixed mortar is high in tensile strength and adhesion stress, less prone to shrinkage cracking and low in cost, and product cost reduction and waste recycling can berealized by application of a great quantity of industrial wastes.

Description

technical field [0001] The invention relates to the technical field of building construction, in particular to a cement-based dry-mixed mortar. Background technique [0002] With the improvement of people's living standards, the requirements for building quality are getting higher and higher. Due to the influence of the technical proficiency of the construction personnel and the quality of various raw materials such as cement and sand, the mortar used on the construction site, whether it is masonry mortar, plastering mortar, or ground leveling mortar, often has cracking phenomena in building plastering mortar ( Even if the most traditional clay brick wall is plastered with cement mortar, there will be large-scale cracking), resulting in unstable project quality, insufficient strength, and even poor quality, which has become a common problem in construction quality. Contents of the invention [0003] The object of the present invention is to overcome the disadvantages of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/00

CPCC04B28/00C04B18/08C04B18/12C04B14/06C04B16/02C04B16/0633C04B22/143C04B2103/0068C04B22/085C04B14/18

Inventor 王生

Owner TIANJIN HONGQUAN CONCRETE MIXING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com