Rotating moment measurement and verification device used for steam generator heat transfer tube mechanical plugging tube

A steam generator and torque technology, applied in measuring devices, force/torque/work measuring instrument calibration/testing, torque measurement, etc., can solve the problems of large size, unstable supply, long supply period , to achieve the effect of high measurement accuracy, simple structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

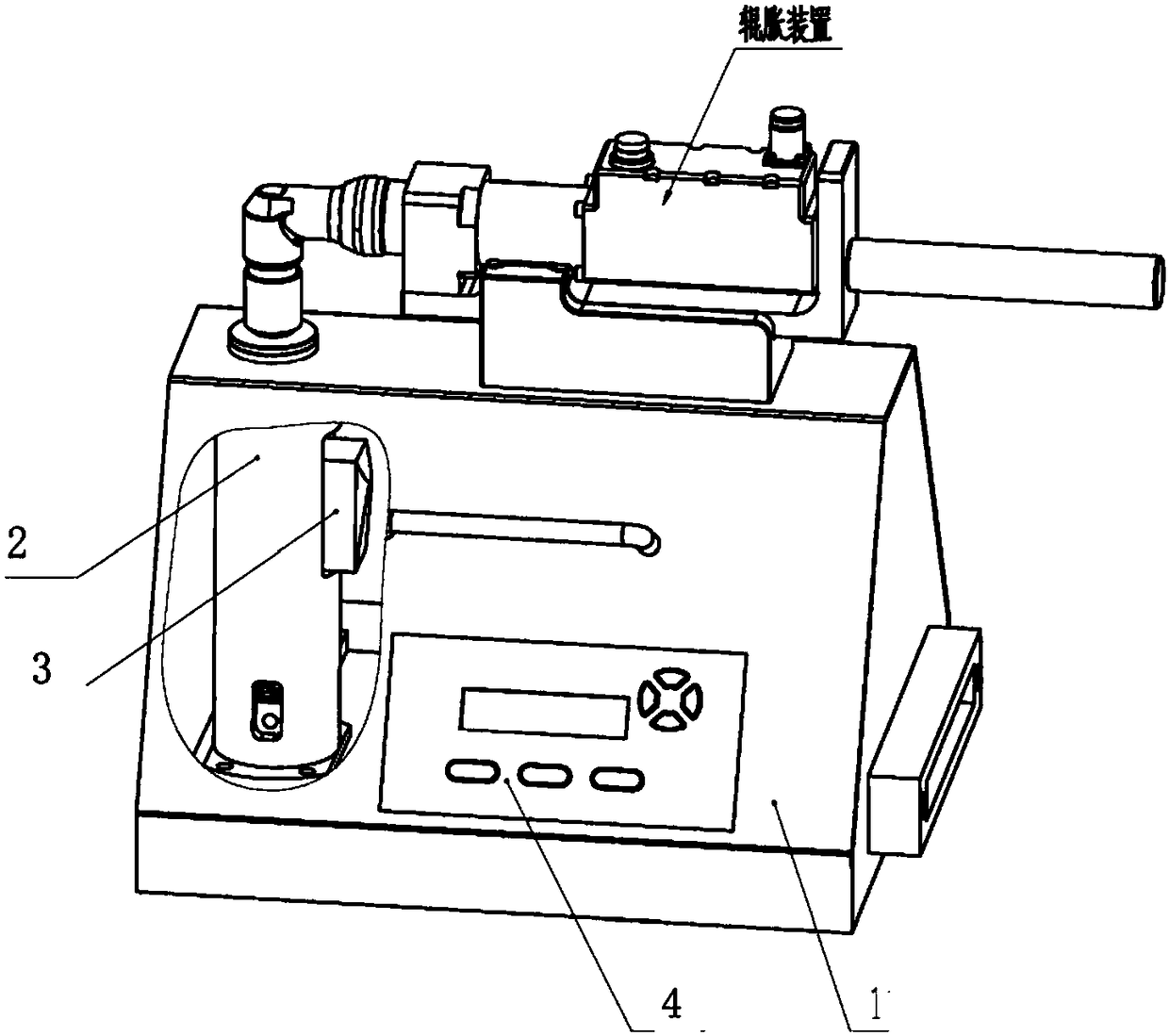

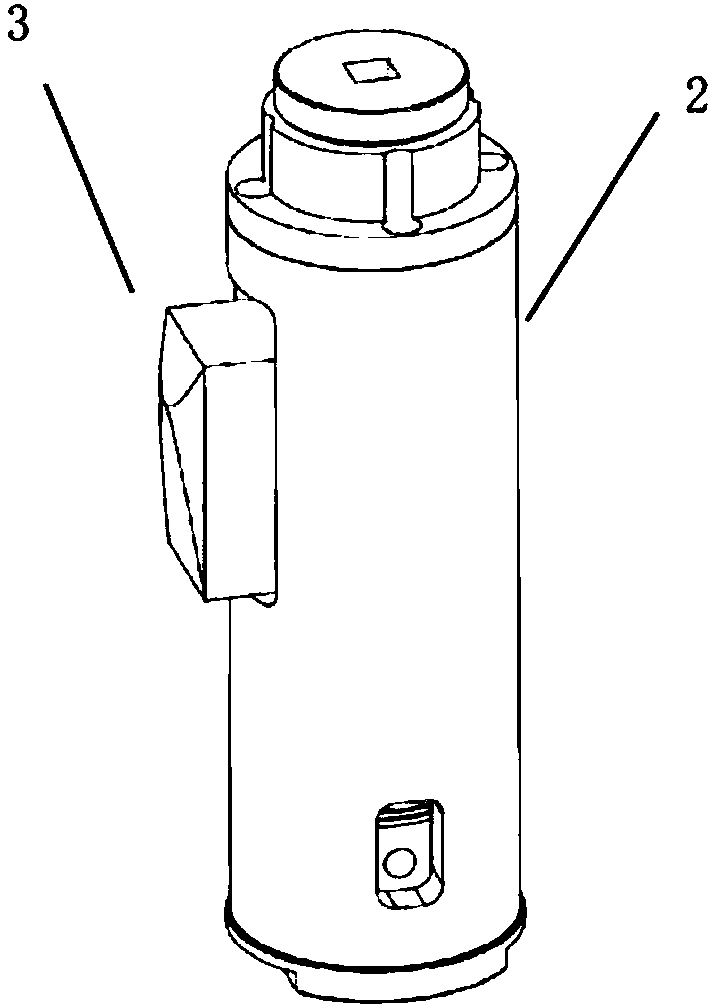

[0023] Such as Figure 1-3 As shown, a rotational torque measurement and verification device for mechanical plugging of steam generator heat transfer tubes includes: mechanical casing 1, analog bolts 2, torque sensor 3 and display 4; mechanical casing 1 is made of stainless steel plate, The upper part is fixed with a special groove, which is used to place the mechanical roller expansion and plugging device. The mechanical housing 1 is fixed with an analog bolt 2 and a display 4. The torque sensor 3 is arranged inside the analog bolt 2, and the torque on the analog bolt 2 The technical parameters are displayed on the display 4 through the torque sensor 3 .

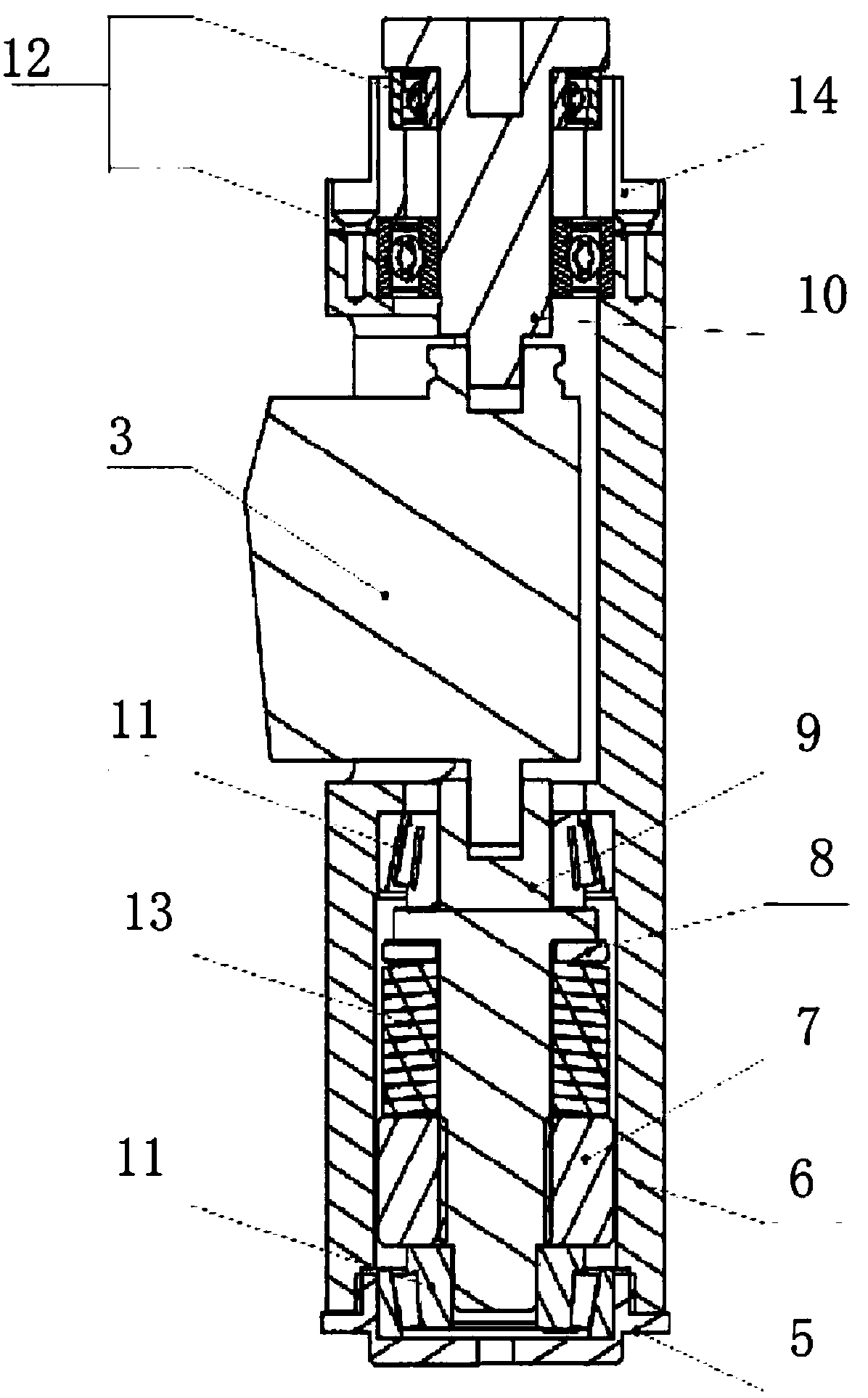

[0024] The simulation bolt 2 has a cylindrical structure as a whole, including: simulation bolt base 5, outer cover 6, nut 7, gasket 8, bolt main shaft 9, output shaft 10, tapered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com