An analysis and testing method based on forced lithium battery internal short circuit

An internal short-circuit, analysis and testing technology, applied in short-circuit testing, measuring electricity, measuring devices, etc., can solve problems such as personal and property damage, fire and explosion, inability to present internal short-circuit relationships, etc., to improve test accuracy and efficiency, and prolong life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

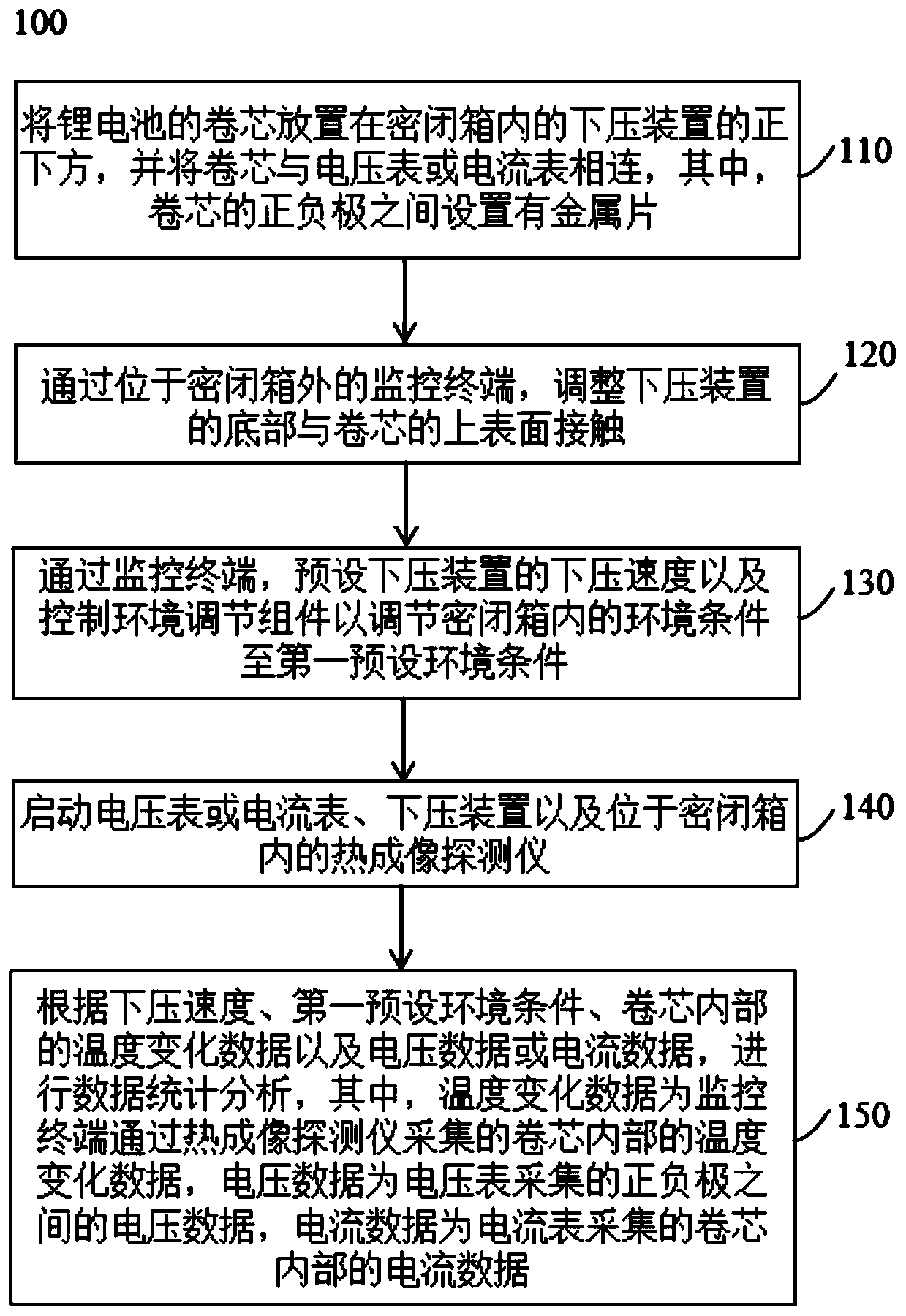

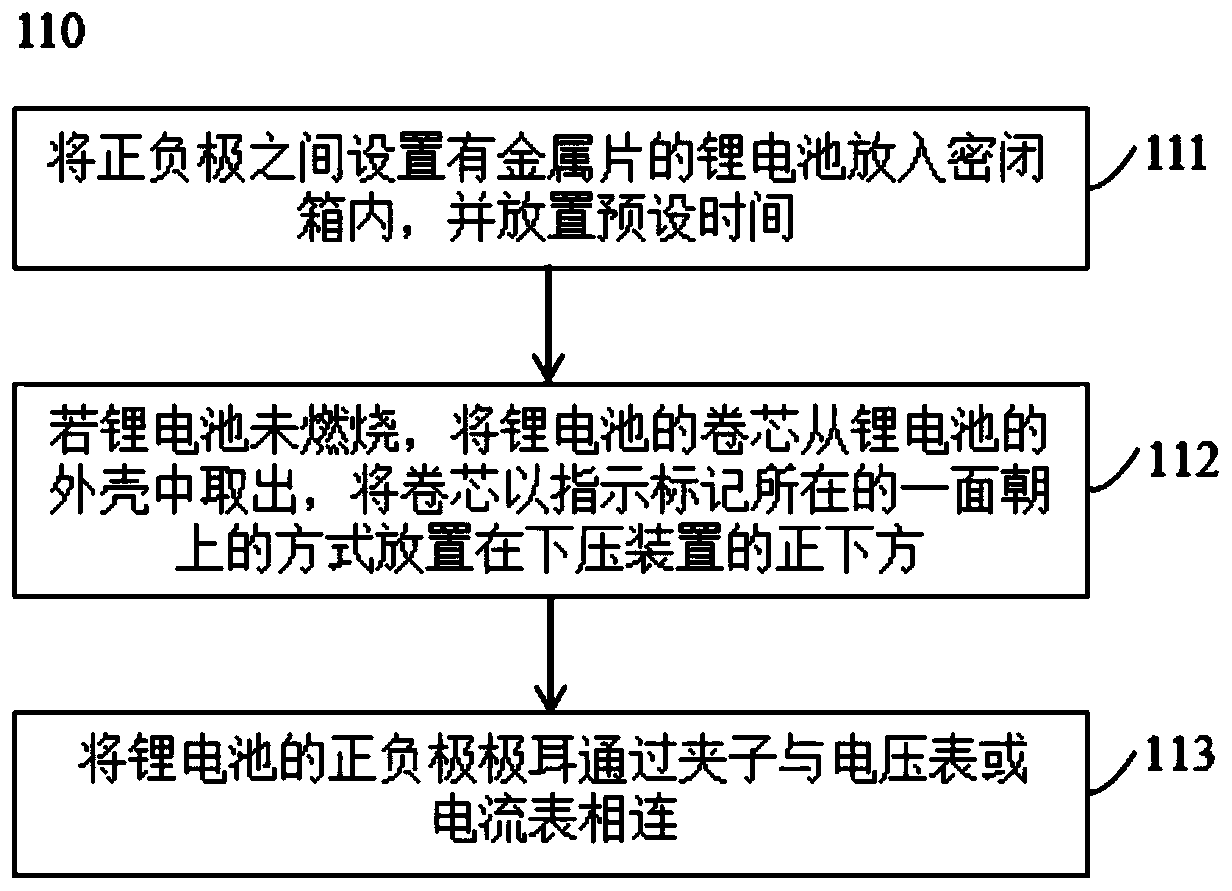

[0046] A kind of analytical test method 100 based on forced lithium battery internal short circuit, such as figure 1 shown, including:

[0047] Step 110, place the winding core of the lithium battery directly under the pressing device in the airtight box, and connect the winding core to a voltmeter or an ammeter, wherein a metal sheet is arranged between the positive and negative electrodes of the winding core.

[0048] Step 120, through the monitoring terminal located outside the airtight box, adjust the bottom of the pressing device to be in contact with the upper surface of the winding core.

[0049] Step 130, through the monitoring terminal, preset the pressing speed of the pressing device and control the environment adjustment component to adjust the environment condition in the airtight box to the first preset environment condition.

[0050] Step 140, start the voltmeter or ammeter, the pressing device and the thermal imaging detector located in the airtight box.

[00...

Embodiment 2

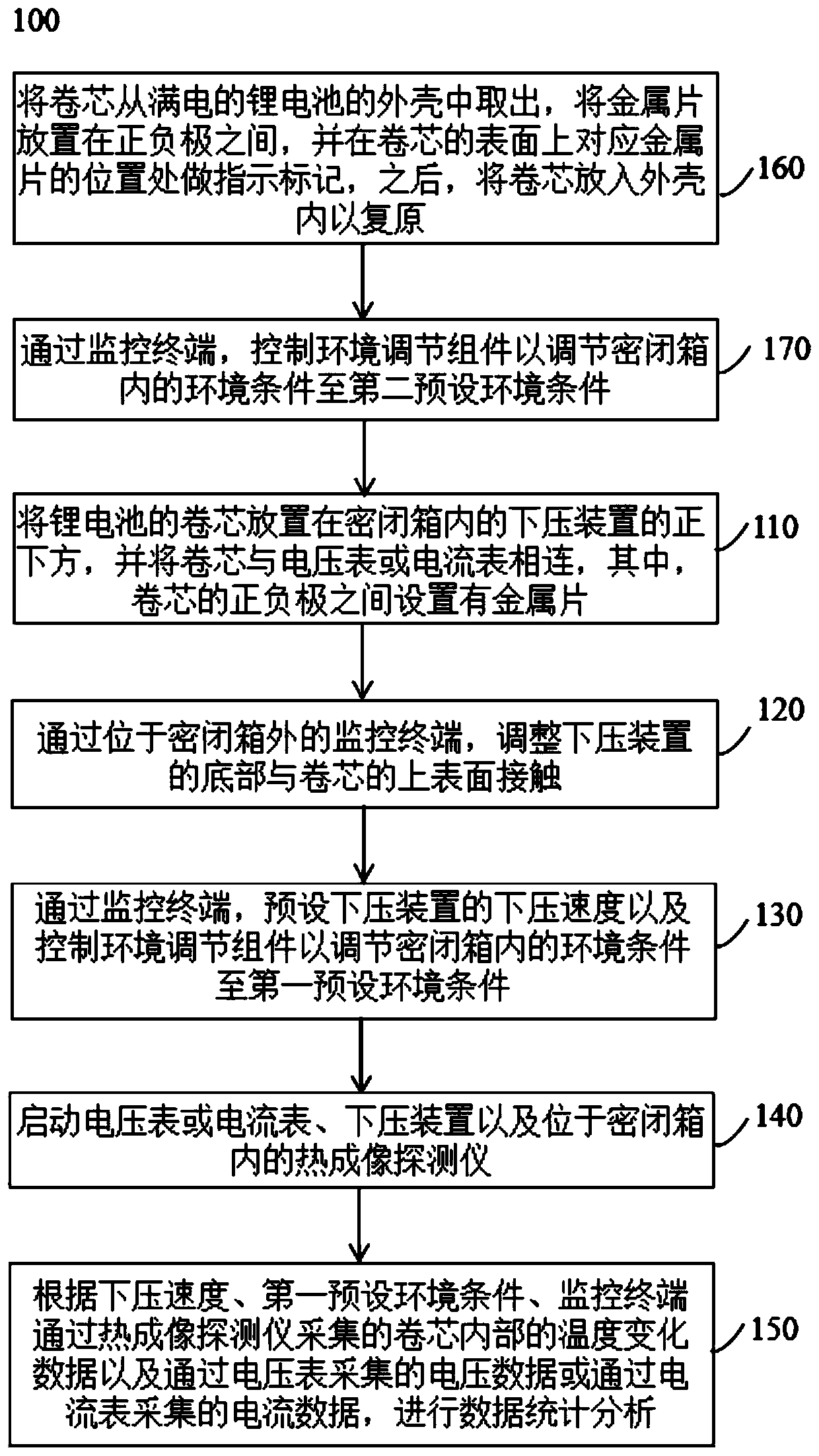

[0054] On the basis of Example 1, as figure 2 As shown, before step 110, method 100 also includes:

[0055] Step 160, take out the winding core from the shell of the fully charged lithium battery, place the metal sheet between the positive and negative electrodes, and mark the corresponding position of the metal sheet on the surface of the winding core, and then place the winding core Place inside case to restore.

[0056] Step 170, through the monitoring terminal, control the environment adjustment component to adjust the environment condition in the airtight box to the second preset environment condition.

[0057] Mark the surface of the winding core, and put the lithium battery into the airtight box. It is not easy for people to remember which side the metal sheet is placed on because the lithium battery is turned over, so before putting the lithium battery into the airtight box, check the The battery is marked to facilitate subsequent operation in the airtight box.

[...

Embodiment 3

[0060] On the basis of Embodiment 1 or Embodiment 2, the second preset environmental conditions include: the temperature is 20±5°C, and the dew point is not greater than -25°C.

[0061] Setting a suitable environment for the battery first will help to prolong the life of the battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com