Constant-current source energization machine

A constant current source and energy-enabling technology, applied in the field of capacitors, can solve problems affecting product quality, high labor intensity, and prone to errors, so as to improve the production environment and realize the effect of fully automatic assembly line production layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

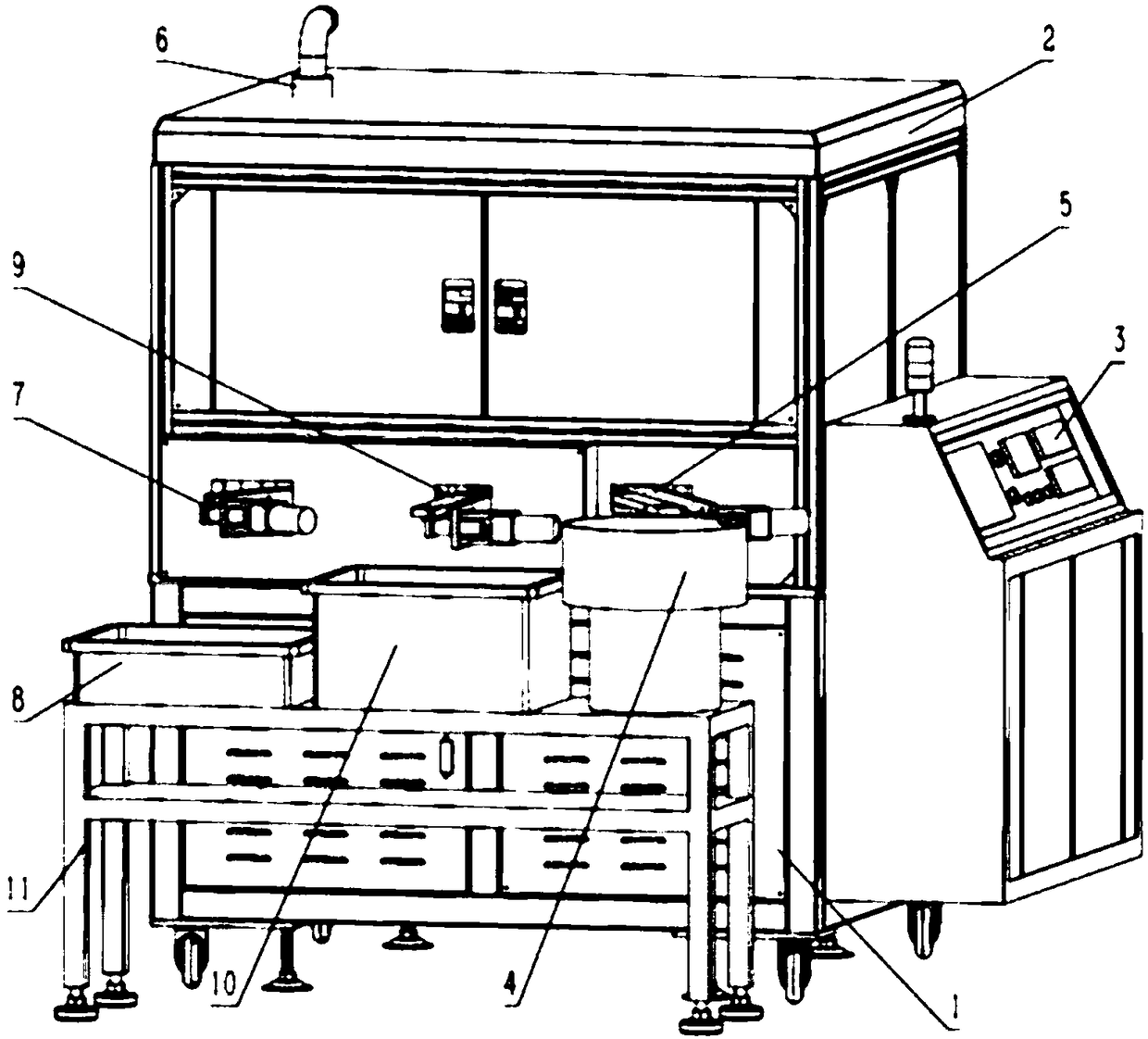

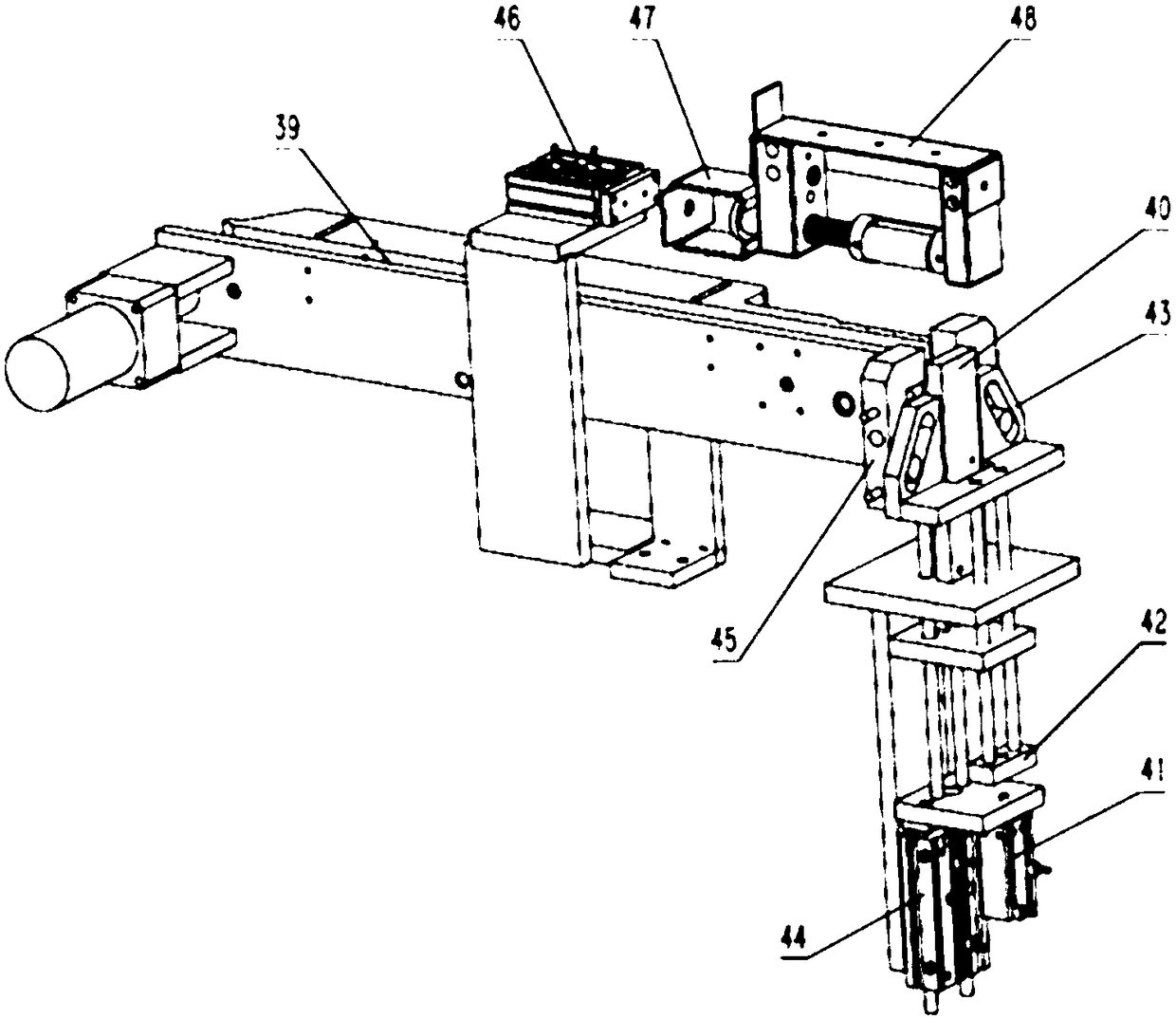

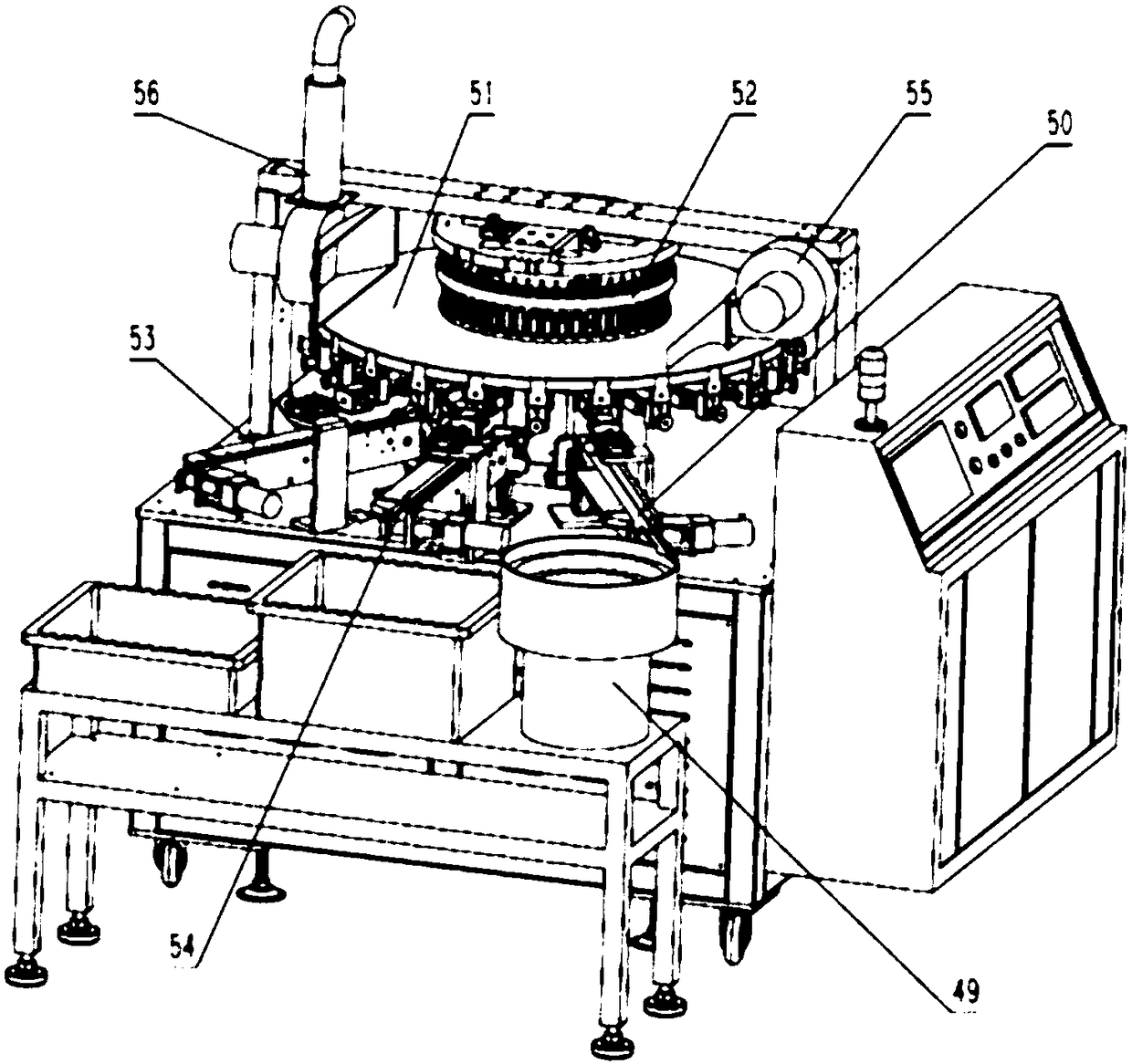

[0010] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach image 3 , a constant current source energizing machine described in this embodiment, which includes an organic base 1, a dustproof shield 2, a control box 3, a vibrating plate 4, a dust exhaust pipe 6, a defective product output port 7, and a good product output port 9. The container support 11, the core turntable mechanism is installed on the top of the machine base 1, the dustproof shield 2 is installed on the machine base 1 outside the core turntable mechanism, the container support 11 is installed on the lower part of the front side of the machine base 1, and the dust protection The middle part of the front side of the cover 2 is provided with a good product output port 9, and the qualified product is installed on the base 1 in the good product output port 9. The conveyor belt 54 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com