Hydraulic support oil cylinder stainless steel connector base welding method

A technology of hydraulic support and welding method, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of insufficient research on stainless steel weldability, and achieve the effect of solving many welding defects, improving welding seam forming, and large penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The welding method of the stainless steel joint seat of the hydraulic support cylinder of the present invention includes the following specific steps:

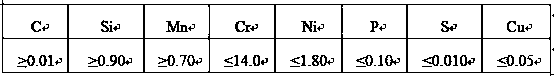

[0020] The first step is to use MAG welding, choose 80%Ar+20%CO 2 The mixed gas is used as the shielding gas, and low-alloy high-strength steel welding wire is selected. The chemical composition of the welding wire is (unit: mass fraction, %): C≤0.10%, Si: 0.40-0.82%, Mn: 1.00-1.30%, Ni: 0.20 -0.80%, Cu≤0.20%, S≤0.001%, P≤0.010%;

[0021] The second step is to preheat the stainless steel joint seat to be welded to 250°C, control the welding current to 200A, the welding voltage to 22V, and the welding speed to perform bottom welding;

[0022] The third step is to maintain the temperature between the weld passes at 250°C, control the welding current 230A, the welding voltage 24V, and the welding speed 500mm / min for filling welding.

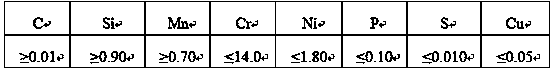

[0023] After testing, the physical and chemical indexes of the welded joint are:

[0024]

[0025]...

Embodiment 2

[0027] The welding method of the stainless steel joint seat of the hydraulic support cylinder of the present invention includes the following specific steps:

[0028] The first step is to use MAG welding, choose 80%Ar+20%CO 2 The mixed gas is used as a shielding gas, and a low-alloy high-strength steel welding wire is used. The chemical composition of the welding wire is (unit: mass fraction, %): C≤0.10%, Si: 0.40-0.82%, Mn: 1.00-1.30%, Ni: 0.20 -0.80%, Cu≤0.20%, S≤0.001%, P≤0.010%;

[0029] The second step is to preheat the stainless steel joint base to be welded to 300°C, control the welding current to 220A, the welding voltage to be 24V, and the welding speed to be 450mm / min for bottom welding;

[0030] The third step is to maintain the temperature between the weld passes at 400°C, control the welding current 250A, the welding voltage 26V, and the welding speed 700mm / min for filling welding.

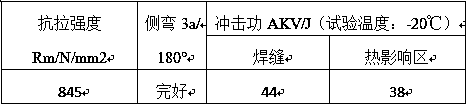

[0031] After testing, the physical and chemical indexes of the welded joint are:

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com