Electromagnetic pulse welding device and working method of metal rubber damping sandwich tube

An electromagnetic pulse, welding metal technology, applied in the field of new metal material welding, can solve problems such as inconvenient processing of base pipe performance, achieve better vibration reduction and impact resistance, good vibration isolation effect, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

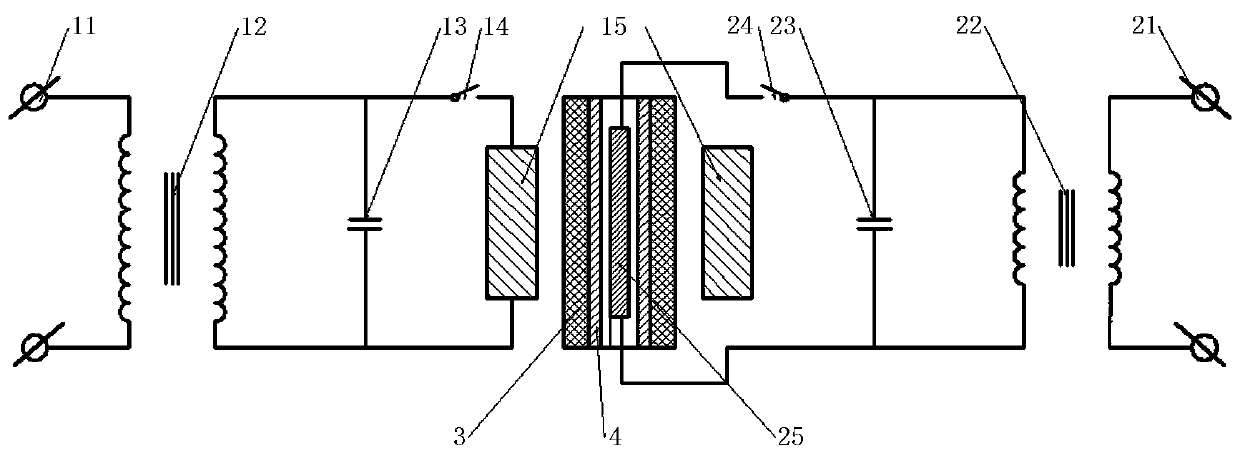

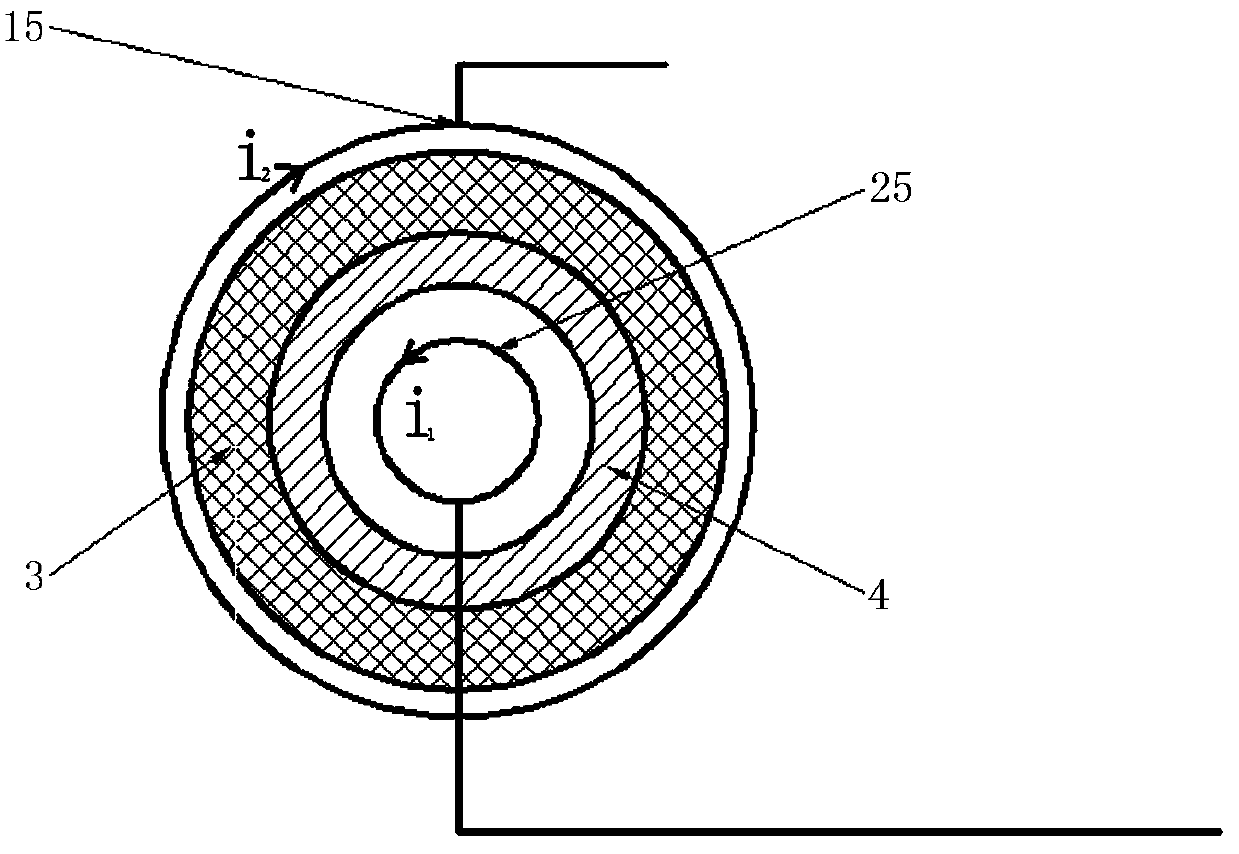

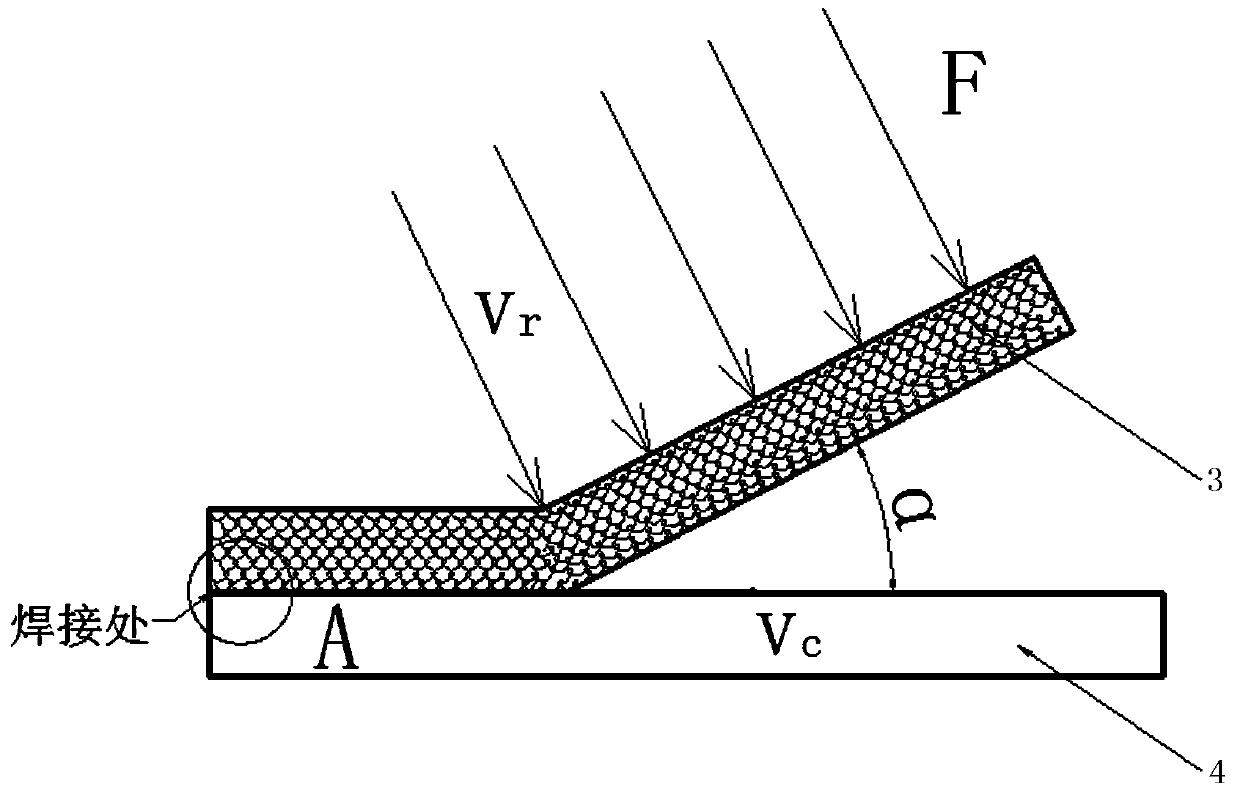

[0029] Such as figure 1 As shown, a device for electromagnetic pulse welding metal rubber damping sandwich tube includes a first electromagnetic pulse module and a second electromagnetic pulse module, the first electromagnetic pulse module includes a first AC power supply 11, a first transformer 12, a first capacitor bank 13. The first high-voltage switch 14 and the first toroidal coil 15. The input end of the first AC power supply 11 is connected to the primary winding input end of the first transformer 12. The first high-voltage switch 14 and the first toroidal coil 15 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com