Grinding and polishing integrated device for curing circular instrument

A kind of instrument and circular technology, which is applied in the field of integrated grinding and polishing equipment, can solve the problems of low efficiency and uneven effect of polishing and waxing maintenance on the surface of the instrument, achieve efficient maintenance operations, improve maintenance efficiency, and improve maintenance effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

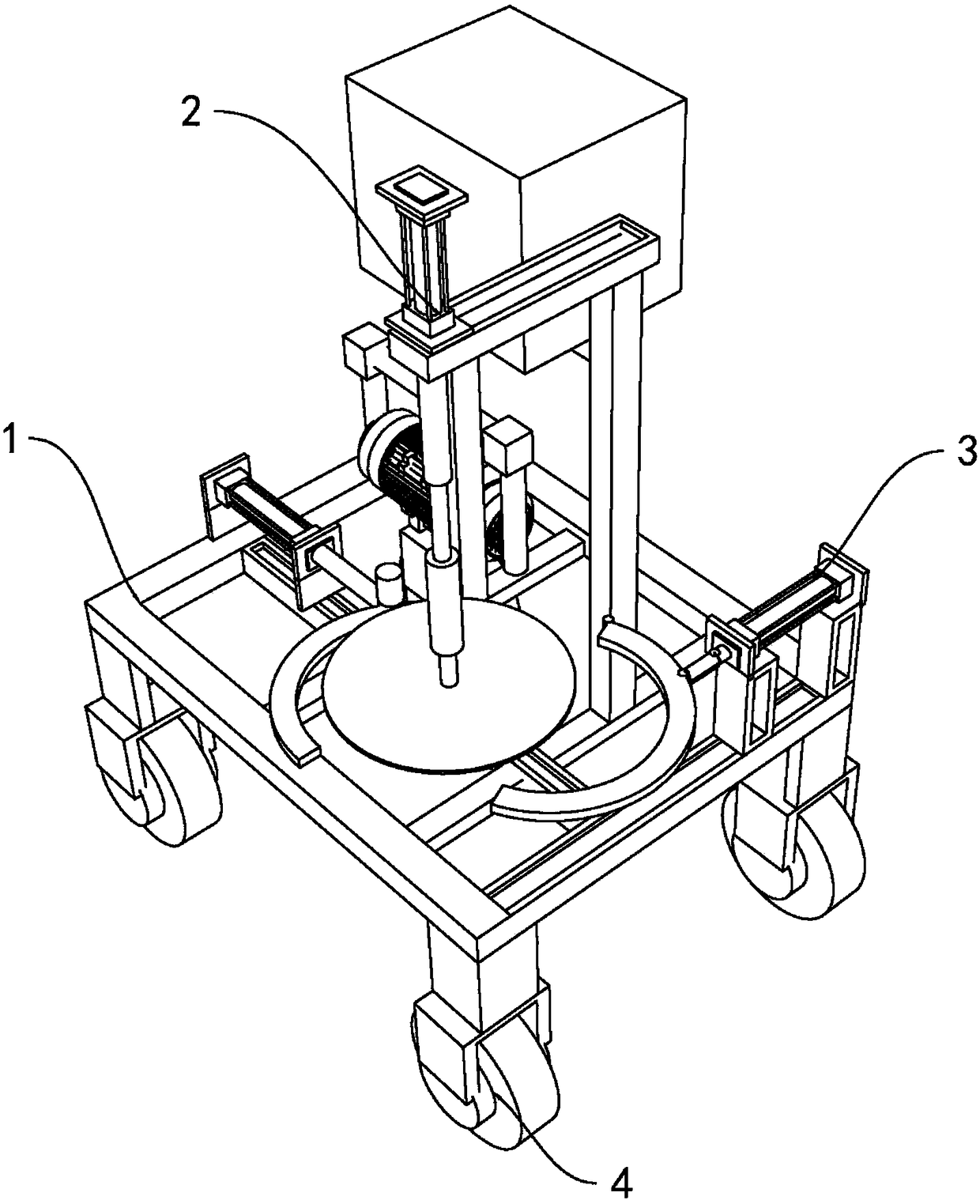

[0025] As shown in the figure, this embodiment provides an integrated grinding and polishing equipment for the maintenance of round instruments, including a counterweight base 1, an integrated grinding and polishing mechanism 2 for grinding and polishing the surface of the instrument, and a clamp for clamping the instrument holding mechanism 3, a folding wheel set 4 for providing displacement, the grinding and polishing integrated mechanism 2 is installed on the counterweight base 1 through a bracket, the clamping mechanism 3 is fixed on the counterweight base 1, and the clamping mechanism 3 Located below the grinding mechanism, the folding wheel set 4 is installed on the four corners of the counterweight base 1;

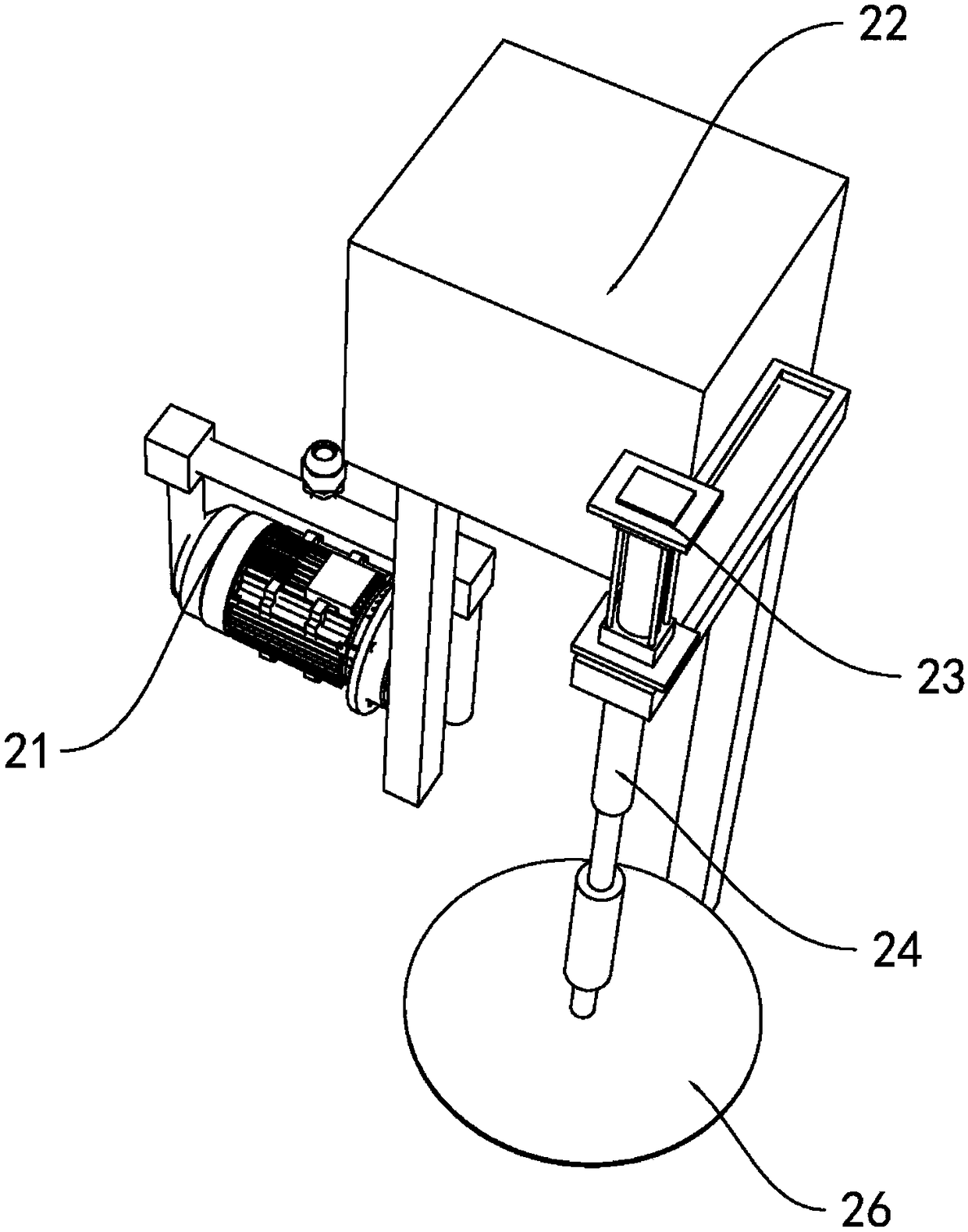

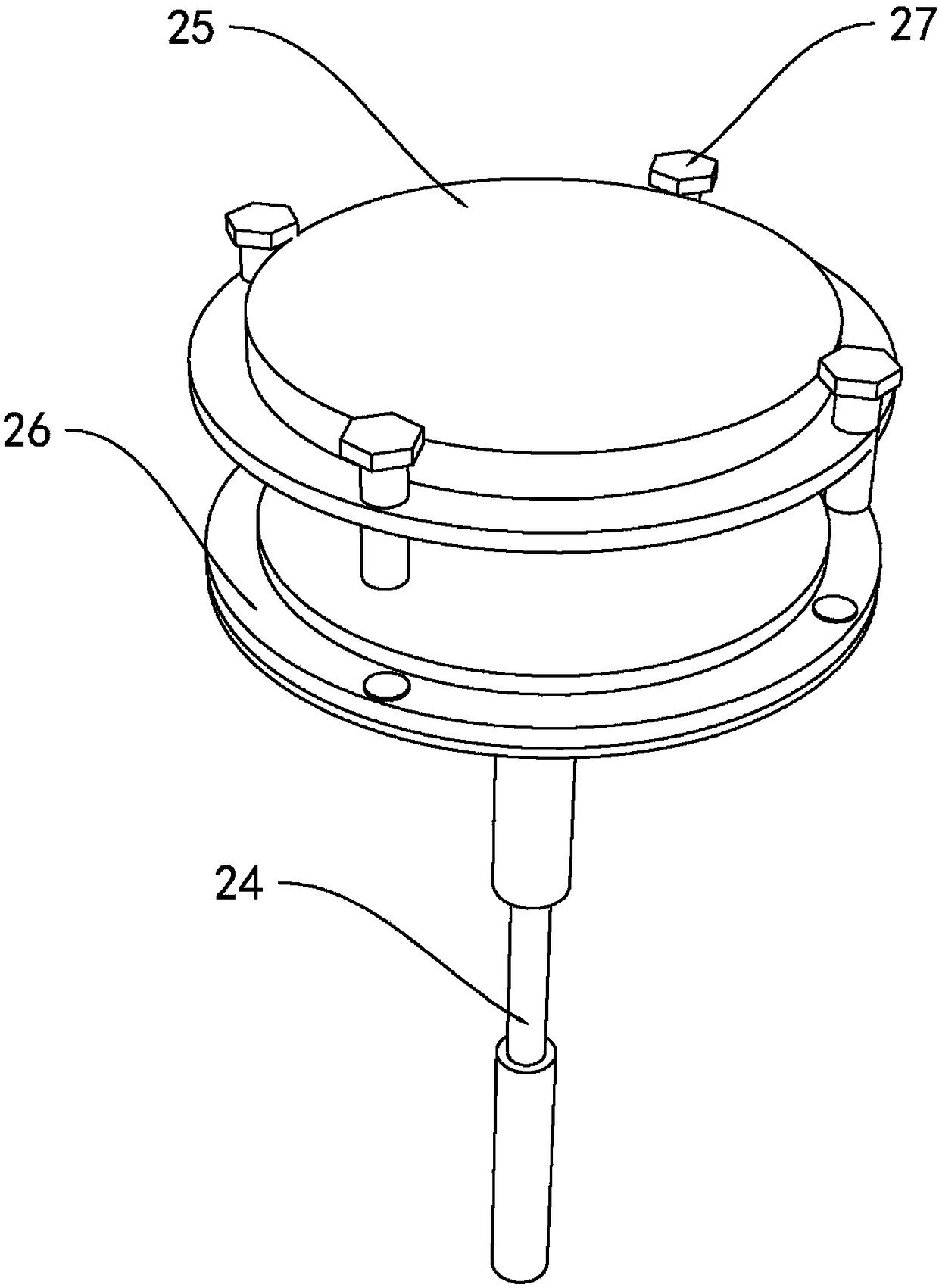

[0026] The grinding and polishing integrated mechanism 2 includes an output motor 21, a gear box 22, a height adjustment cylinder 23, an installation shaft 24, a grinding disc 25, a polishing disc 26, and a stable connection for strengthening the connection between t...

Embodiment 2

[0029] This embodiment makes the following optimizations on the basis of Embodiment 1: As shown in the figure, this embodiment provides an integrated grinding and polishing equipment for round instrument maintenance, including a counterweight base 1, used for grinding and polishing instruments The surface grinding and polishing integrated mechanism 2, the clamping mechanism 3 for clamping the instrument, and the folding wheel set 4 for providing displacement, the grinding and polishing integrated mechanism 2 is installed on the counterweight base 1 through a bracket, and the clamping mechanism 3 is fixed on the counterweight base 1, the clamping mechanism 3 is located below the grinding mechanism, and the folding wheel set 4 is installed on the four corners of the counterweight base 1;

[0030] The grinding and polishing integrated mechanism 2 includes an output motor 21, a gear box 22, a height adjustment cylinder 23, an installation shaft 24, a grinding disc 25, a polishing d...

Embodiment 3

[0034] This embodiment makes the following optimizations on the basis of Embodiment 1: As shown in the figure, this embodiment provides an integrated grinding and polishing equipment for round instrument maintenance, including a counterweight base 1, used for grinding and polishing instruments The surface grinding and polishing integrated mechanism 2, the clamping mechanism 3 for clamping the instrument, and the folding wheel set 4 for providing displacement, the grinding and polishing integrated mechanism 2 is installed on the counterweight base 1 through a bracket, and the clamping mechanism 3 is fixed on the counterweight base 1, the clamping mechanism 3 is located below the grinding mechanism, and the folding wheel set 4 is installed on the four corners of the counterweight base 1;

[0035] The grinding and polishing integrated mechanism 2 includes an output motor 21, a gear box 22, a height adjustment cylinder 23, an installation shaft 24, a grinding disc 25, a polishing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com