Bending method of bamboos in high-temperature and high-pressure steam tank

A high-temperature, high-pressure, steam tank technology, which is applied in wood bending, wood treatment, wood heating, etc., can solve problems such as difficulty in achieving uniform bending components, inconsistent colors of bent parts, and darkening of local colors, so as to avoid the inconsistency of the overall color , The overall color is consistent, and the effect of reducing hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A method for bending bamboo in a high-temperature and high-pressure steam tank, comprising the steps of:

[0025] S1. Open up the inner section of the bamboo pole with a length of 1200mm and a diameter of 50mm;

[0026] S2. Pour clean sand into the round bamboo pole and seal the inner cavities at both ends. Do not seal the cross-section of the bamboo wall, so as to facilitate the entry and exit of gaseous and liquid moisture during the softening and bending process;

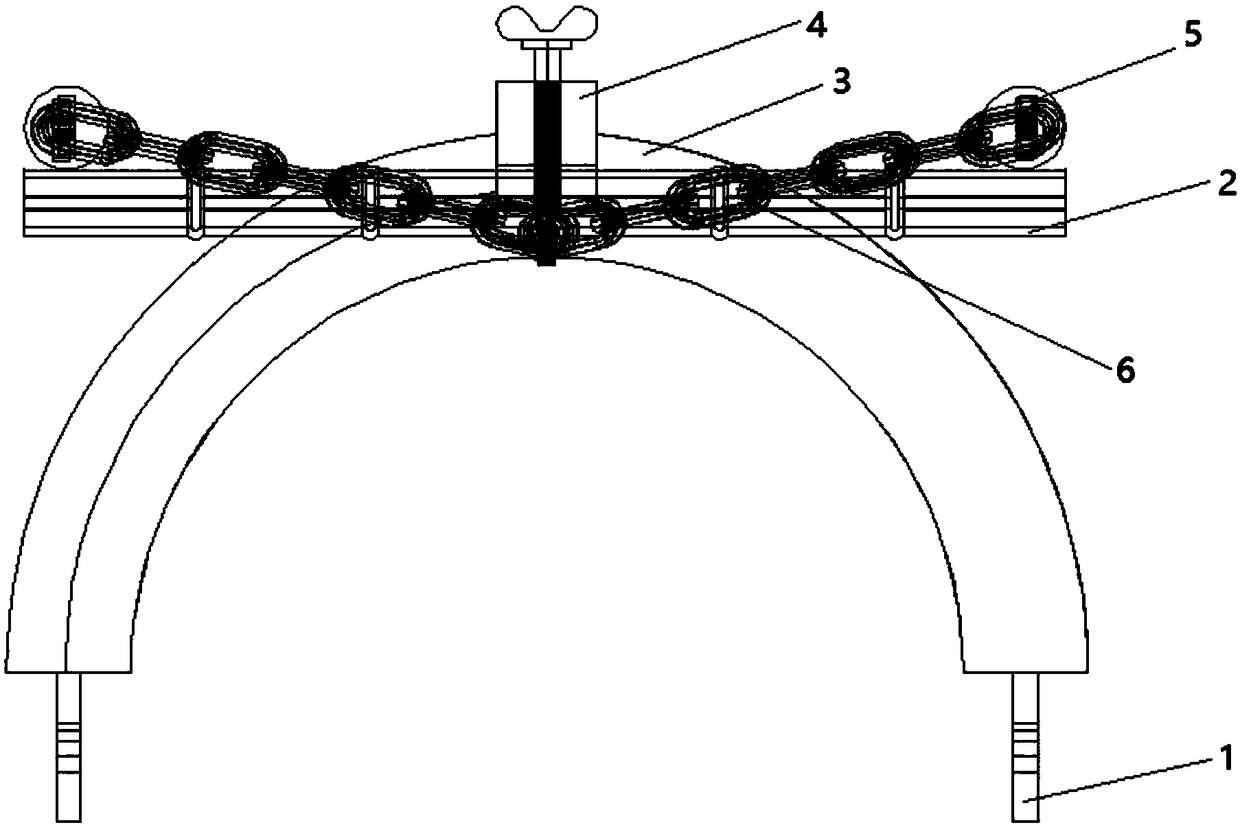

[0027] S3, placing the bamboo pole in the U-shaped groove 3 on the special bending mold frame with rollers and utilizing the steel bar 4 to fix the bamboo pole to prevent the bamboo pole from moving during softening and bending;

[0028] S4, the heavy object round iron bar 5 that chain 6 is connected is placed on the both sides of fixed iron bar 4;

[0029] S5, push the curved mold rack cart loaded with bamboo poles into the high-temperature steam tank with tracks and close it;

[0030] S6. Turn on the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com