Continuous production equipment set for pre-stressed track plates

A complete set of equipment and track slab technology, which is applied in the field of continuous production of prestressed track slab complete sets of equipment, can solve problems such as low labor efficiency and difficulty in ensuring product quality, and achieve the effect of realizing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

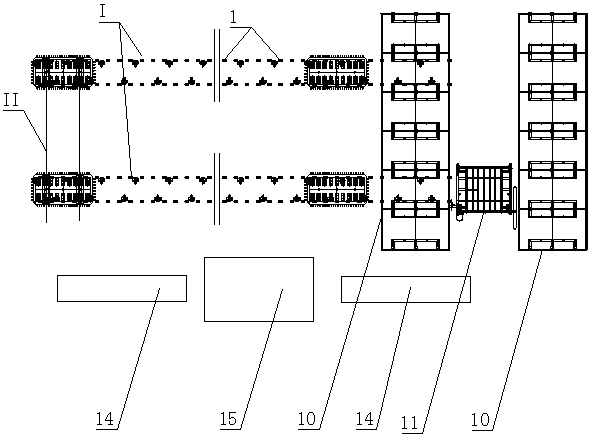

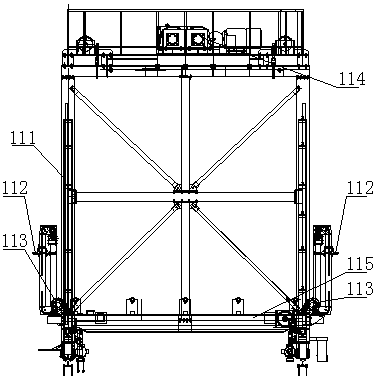

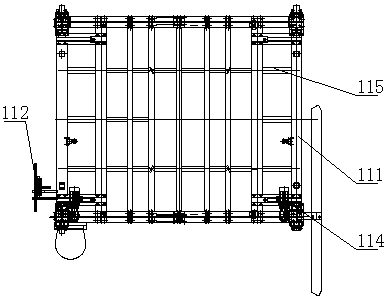

[0045] Such as figure 1 As shown, the present invention provides an example of a complete set of equipment for the continuous production of prestressed track plates, which includes demoulding process equipment, mold cleaning process equipment, pre-assembly process equipment and pouring equipment that are sequentially distributed from front to back. Among them, the demoulding process equipment includes the top side bolt mechanism, the tensioning mechanism, the disassembling mechanism and the demolding mechanism. The mold cleaning process equipment includes the mold cleaning mechanism and the spraying mechanism. The pre-assembly process equipment includes the embedded casing installation mechanism, Reinforcement cage moulding mechanism, threading mechanism, initial tensioning mechanism, cushion block placement mechanism, tensioning mechanism and insulation monitoring mechanism. Pouring equipment includes pouring mechanism, vibrating mechanism and napping mechanism. figure 1 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com