Fiber reinforced composite material anti-collision beam

A composite material, fiber reinforced technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of increased fuel consumption, easy deformation and damage, no energy absorption, etc., to improve impact resistance and structural stability. The effect of good and excellent cushioning properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

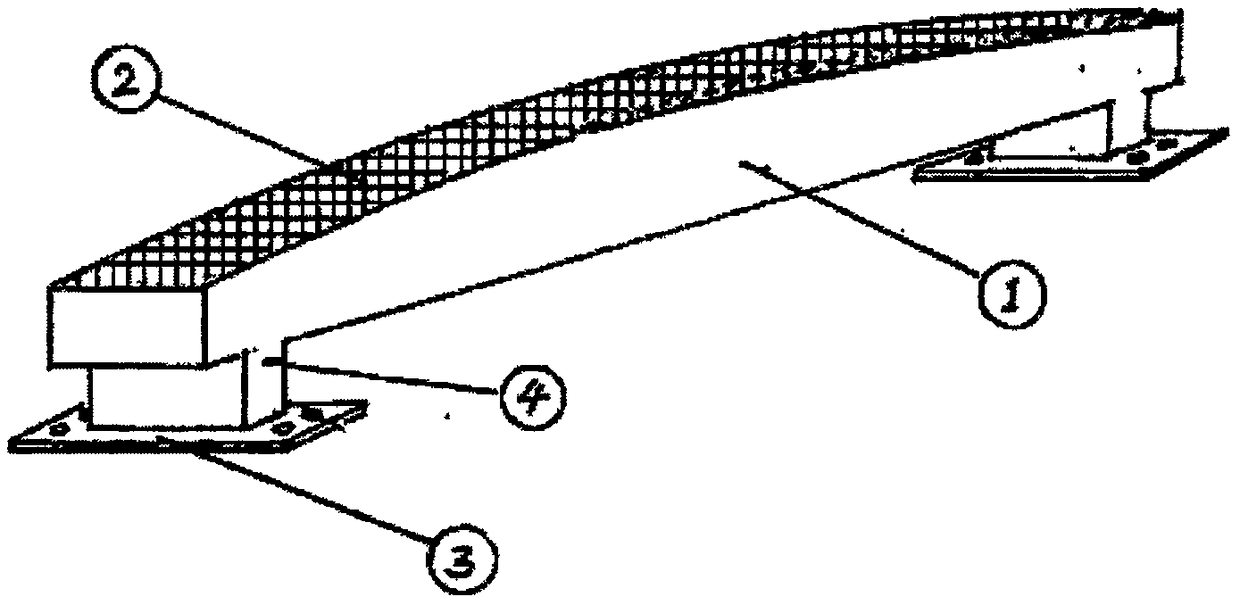

[0019] As shown in the figure, the present invention provides a fiber-reinforced composite material anti-collision beam. The anti-collision beam is an integrated structure, including a main body (1) of the anti-collision beam, and a pillar (4) is arranged at each end of the pillar. A connecting plate (3) is provided, and the two anti-collision beam connecting plates are connected with the vehicle frame longitudinal beam. The structure is made of fiber-reinforced resin-based composite light-body material, and adopts a quadrilateral honeycomb porous cavity structure (2). The reinforcing fiber of the fiber-reinforced resin composite material is glass fiber, and the resin used is epoxy resin. The anti-collision beam connecting plate (3) and the vehicle frame longitudinal beam can be connected by bolts.

[0020] A fiber-reinforced composite anti-collision beam is made by molding. First, the reinforcing fiber and resin are mixed in proportion, heated to above the softening point an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com