Amorphous alloy composite shell and forming method and application thereof

An amorphous alloy and shell technology, which is applied to an amorphous alloy composite shell and its forming method and application fields, can solve the problems of not being recognized by consumers, difficult to use the shell, affecting the communication function, etc., and achieve good electromagnetic signal reception. and emission intensity, reducing the probability of deformation and damage, reducing the effect of product weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

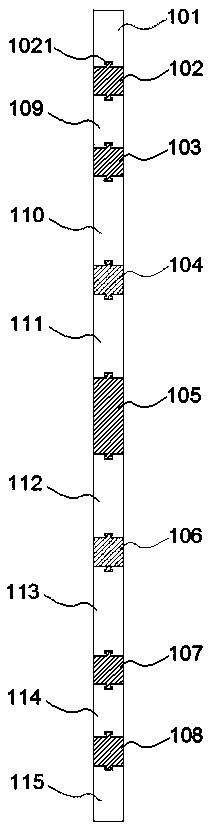

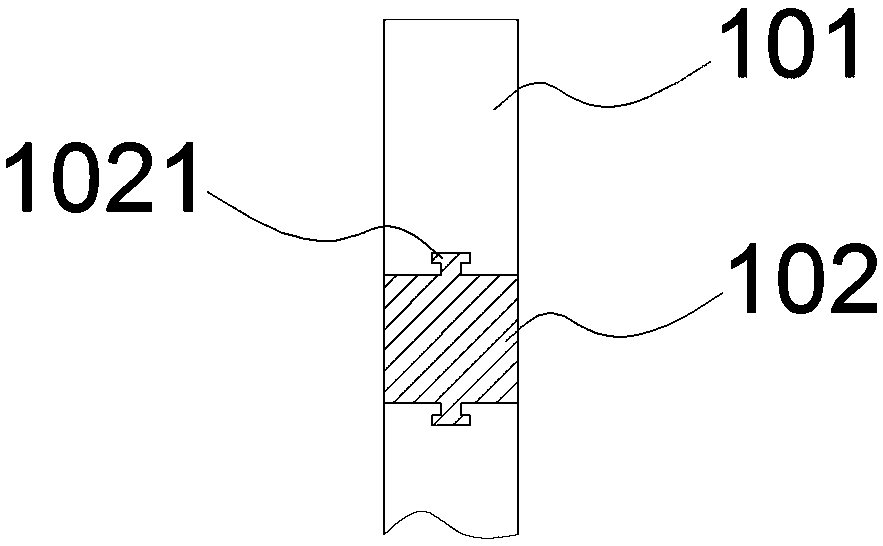

[0033] The amorphous alloy composite shell structure in Example 1 of the present invention is as attached figure 1 As shown, the schematic diagram is a cross-sectional schematic diagram of the side of the amorphous alloy composite shell. It can be seen from the accompanying drawings that it includes an amorphous alloy prefabricated component and a plastic bonding component. In this embodiment, the amorphous alloy prefabricated component includes an amorphous alloy prefabricated part 101, 109, 110, 111, 112, 113, 114, 115, the plastic bonding components include plastic bonding parts 102, 103, 104, 105, 106, 107, 108, the amorphous alloy prefabricated parts are all set as strips, and the plastic bonding parts It is a strip with the same thickness, and the amorphous alloy prefabricated parts and the plastic bonding parts are arranged at intervals, such as a plastic bonding part 102 between the amorphous prefabricated parts 101 and 109, and a plastic bonding part Plastic joint 104...

Embodiment 2

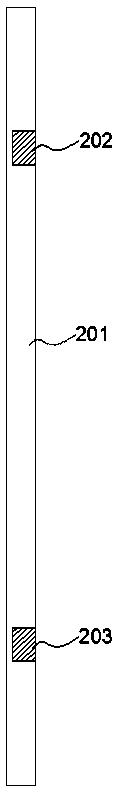

[0040] The amorphous alloy composite shell structure in Example 2 of the present invention is as attached image 3 As shown, the schematic diagram is a cross-sectional schematic diagram of the side of the amorphous alloy composite shell, which is attached image 3 It can be seen that it includes amorphous alloy prefabricated components and plastic bonded components. In this embodiment, the amorphous alloy prefabricated component includes an amorphous alloy prefabricated part 201, and the plastic bonded component includes plastic bonded parts 202 and 203. The amorphous alloy prefabricated parts are all set to In strip shape, the plastic bonding part is embedded in the amorphous alloy prefabricated part and has a thickness of 60-80% of the amorphous alloy prefabricated part. The above-mentioned structural features are suitable for a specific position in the internal structure that requires an additional anti-electromagnetic shielding function. At the same time, the outer surface...

Embodiment 3

[0046] The amorphous alloy composite shell structure in Example 3 of the present invention is as attached Figure 4 As shown, the schematic diagram is a cross-sectional schematic diagram of the side of the amorphous alloy composite shell, which is attached Figure 4 It can be seen that it includes amorphous alloy prefabricated components and plastic bonded components. In this embodiment, the amorphous alloy prefabricated component includes an amorphous alloy prefabricated part 301, and the plastic bonded component includes plastic bonded parts 302 and 303. The amorphous alloy prefabricated part 301 is a knuckle shape, and the plastic bonding part is a strip or plate-like structure that fits at the corners of the amorphous alloy prefabricated part. The above structural features are suitable for applications with particularly high requirements for light weight. In this embodiment, the thickness of the amorphous alloy prefabricated part can be as low as 0.05mm. After adding plast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com