Gasifier device for efficient slag removal with separation and heat recovery

A technology of heat recovery and gasification furnace, which is applied in the field of coal chemical industry, can solve the problems of inability to run stably for a long period, dust accumulation in the heat exchange system, serious slag accumulation, etc., to achieve long-term stable operation, ensure normal operation, and reduce the amount of sewage little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

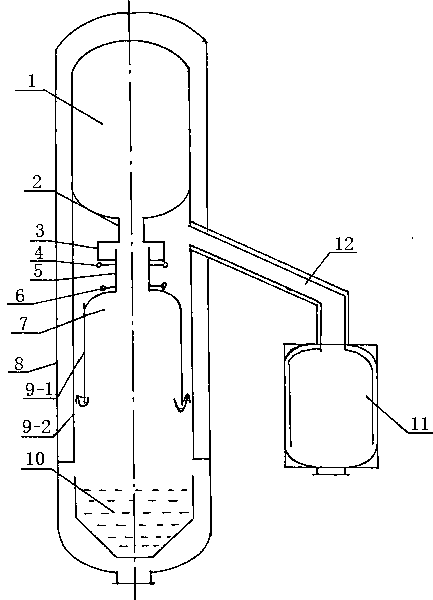

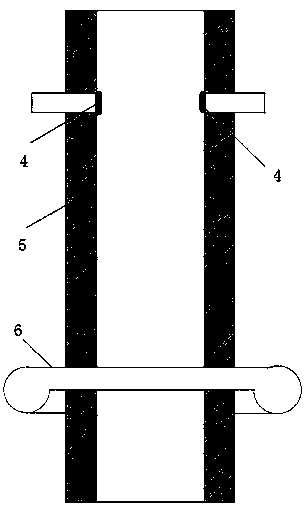

[0015] The present invention as figure 1 , 2 As shown, it includes a throat 5 and a slag-gas separator 7. The gasifier 1 is at the upper end of the slag-gas separator 7, and the outlet of the gasifier is facing the inlet of the slag-gas separator 7, and communicates with each other through the throat 5. The slag The outer wall of the gasification separator 7 forms an annular gap with the inner wall of the furnace, and a gas outlet is designed on the furnace body above the annular gap, leaving the gasification furnace and entering the waste heat boiler 11, and the upper part of the throat pipe 5 is facing the gasification furnace outlet , connected with the outlet of the gasifier, a water tank distributor 3 is designed on the top of the throat pipe 5 to evenly overflow the water to the inner wall of the throat pipe 5 to form a liquid film to protect the inner wall; the water tank distributor 3 of the throat pipe 5 is installed with a spray To the water nozzle 4 inside the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com