Evaporation cooling/air cooling heat exchange composite type condenser

An air-cooled heat exchanger and evaporative cooling technology, applied in evaporator/condenser, heating mode, refrigerator, etc., can solve the problems of scaling on the surface of heat exchange tubes, affecting heat exchange efficiency, freezing of circulating water, etc. To achieve the effect of reducing energy consumption, improving operating performance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

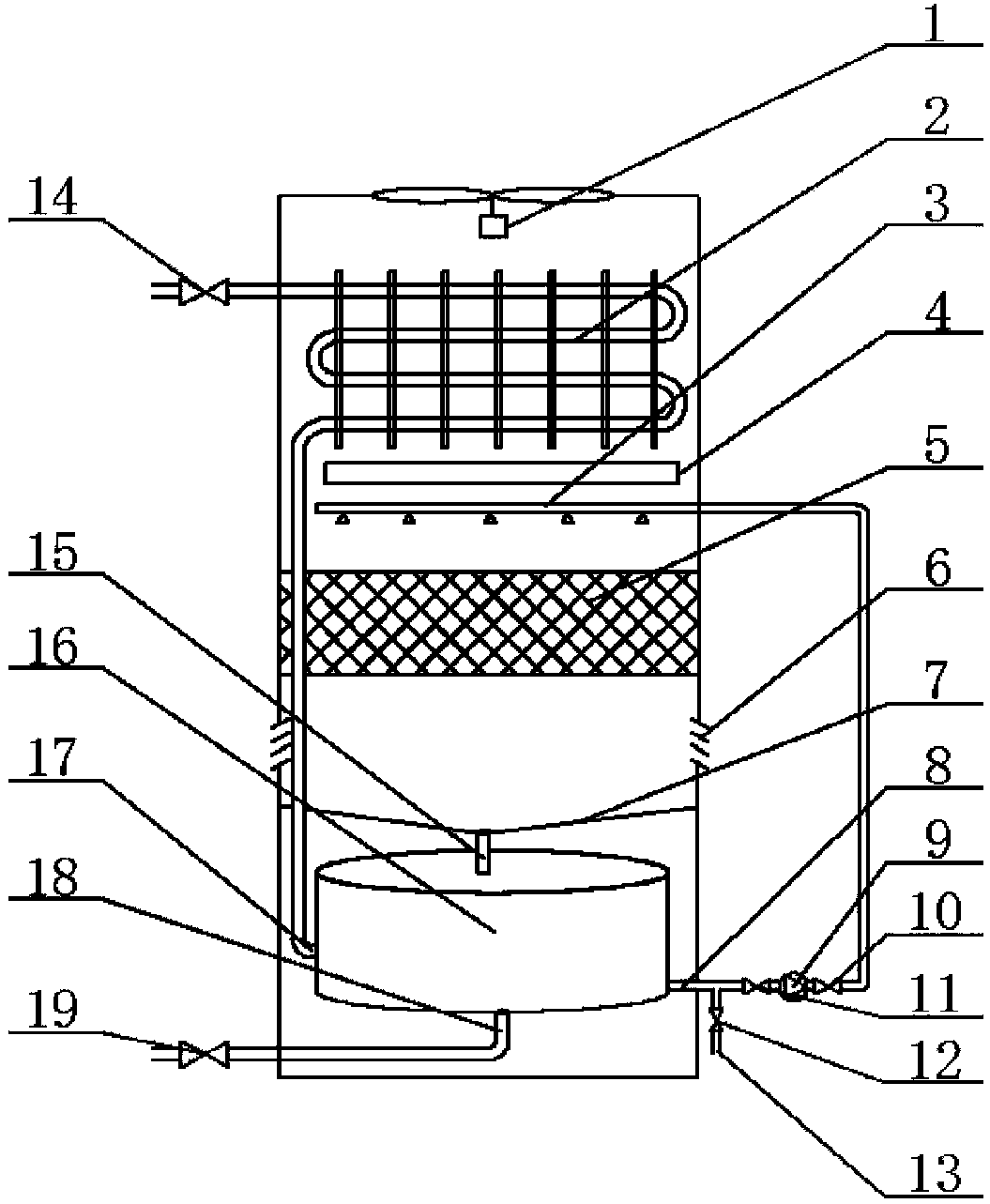

[0025] Such as figure 1 As shown, the evaporative cooling / air-cooled heat exchange composite condenser of the present invention includes: fan 1, air-cooled heat exchanger 2, spray system 3, water baffle 4, heat dissipation filler 5, louvers 6, water collecting tray 7 , circulating water pump 9 and water-cooled heat exchanger 16. The air-cooled heat exchanger 2 is a finned heat exchange coil. The heat exchange area of the air and air-cooled heat exchanger can be increased by arranging the fins, and the heat exchange effect can be enhanced.

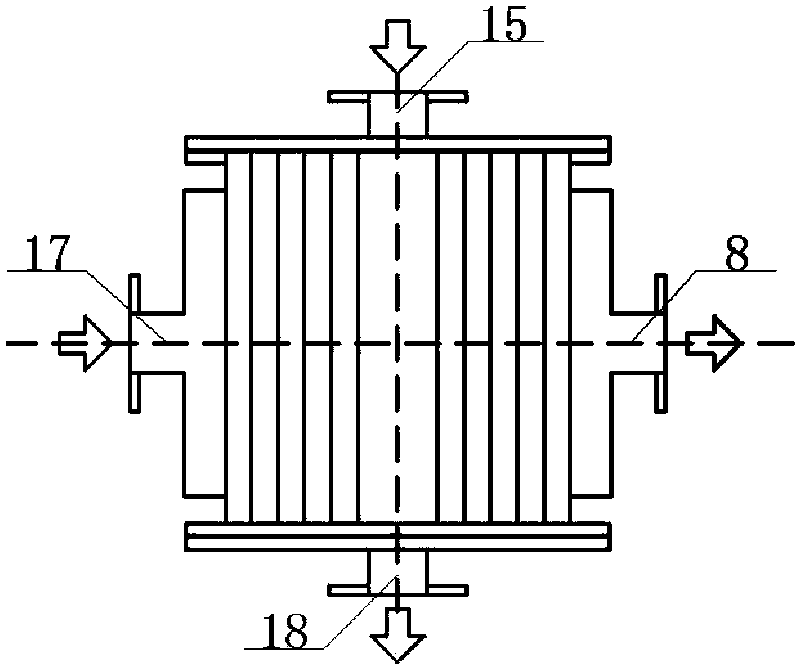

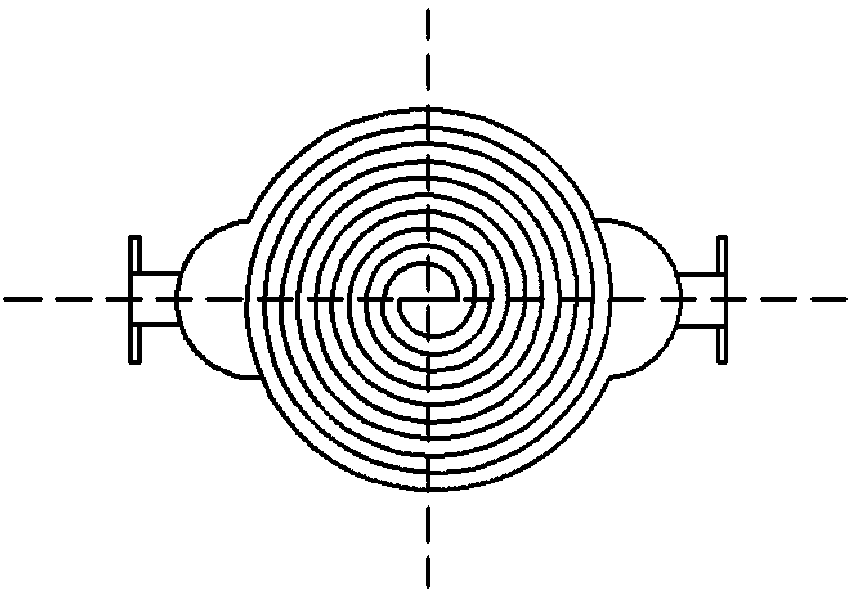

[0026] Such as figure 2 with image 3 As shown, the water-cooled heat exchanger 16 is a spiral plate heat exchanger, which is made of two parallel steel plates to form spiral flow channels separated from each other, with cover plates welded on the upper and lower sides, and the hot and cold fluids flow in the two flow channels respectively. . The water-cooled heat exchanger 16 is provided with a first inlet 17 , a second inlet 15 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com