Drying device for sauce ingredients

A drying device and drying chamber technology, applied in drying, drying machine, heating device and other directions, can solve the problem of unfavorable long-term use of the drying device, increase the structural complexity of the drying furnace, affect the drying efficiency, etc. problems, to achieve the effect of improving work efficiency, shortening drying time, and simplifying the composition structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

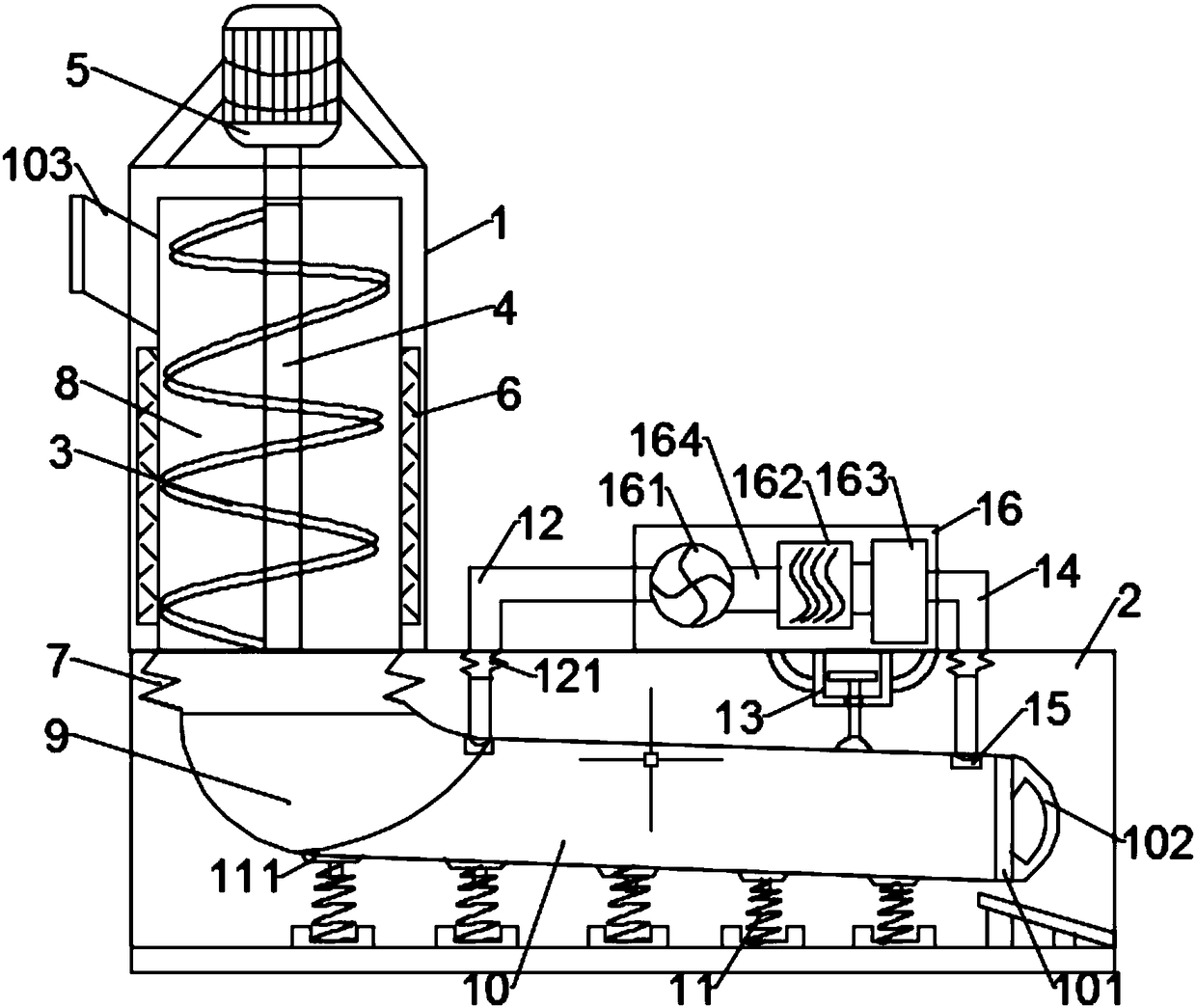

[0027] Such as figure 1 As shown, the present invention provides a drying device for sauce ingredients, including an electric heating drying chamber 1 and a hot air drying chamber 2, and the electric heating drying chamber 1 is fixedly installed at the top of the hot air drying chamber 2 , and the middle of the electric heating drying chamber 1 is provided with a Jiaolong conveyor 3, wherein a feeding port 103 is installed on the side wall of the electric heating drying chamber 1, and the feeding port 101 is arranged on the electromagnetic heating The top of the coil 6 is used to load the sauce raw materials to be dried, the motor 5 is connected to the top of the rotating shaft 4 of the Jiaolong conveyor 3, and an electromagnetic heating coil is installed on the outer peripheral chamber wall of the lower part of the Jiaolong conveyor 3 6. A telescopic rubber tube 7 is arranged below the electromagnetic heating coil 6, and the telescopic rubber tube 7 communicates the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com