Constant and fatigue stress testing device and testing method

A technology of fatigue stress and testing equipment, which is applied in the direction of measuring equipment, testing material strength by applying stable tension/pressure, testing material strength by applying repetitive force/pulsation force, etc. Well simulate the damage process of structural parts and other problems to achieve the effect of solving the problem of synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

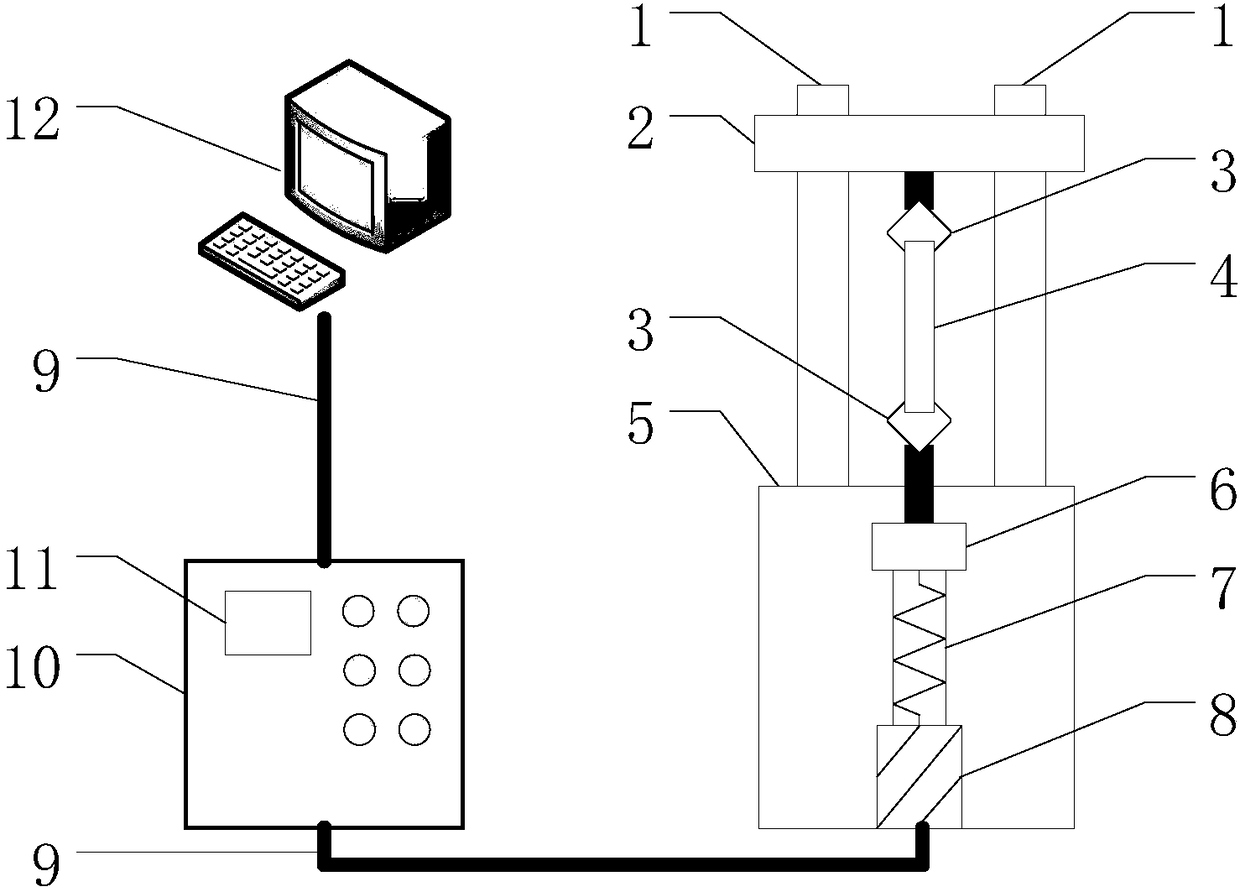

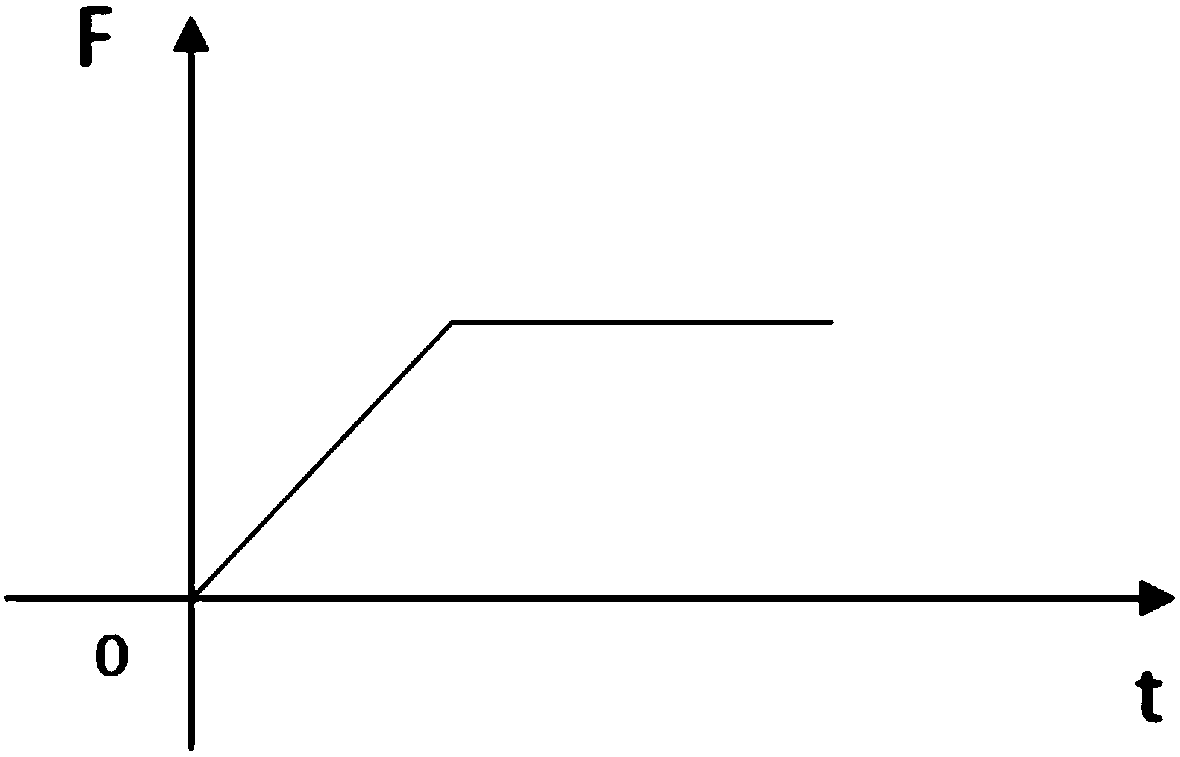

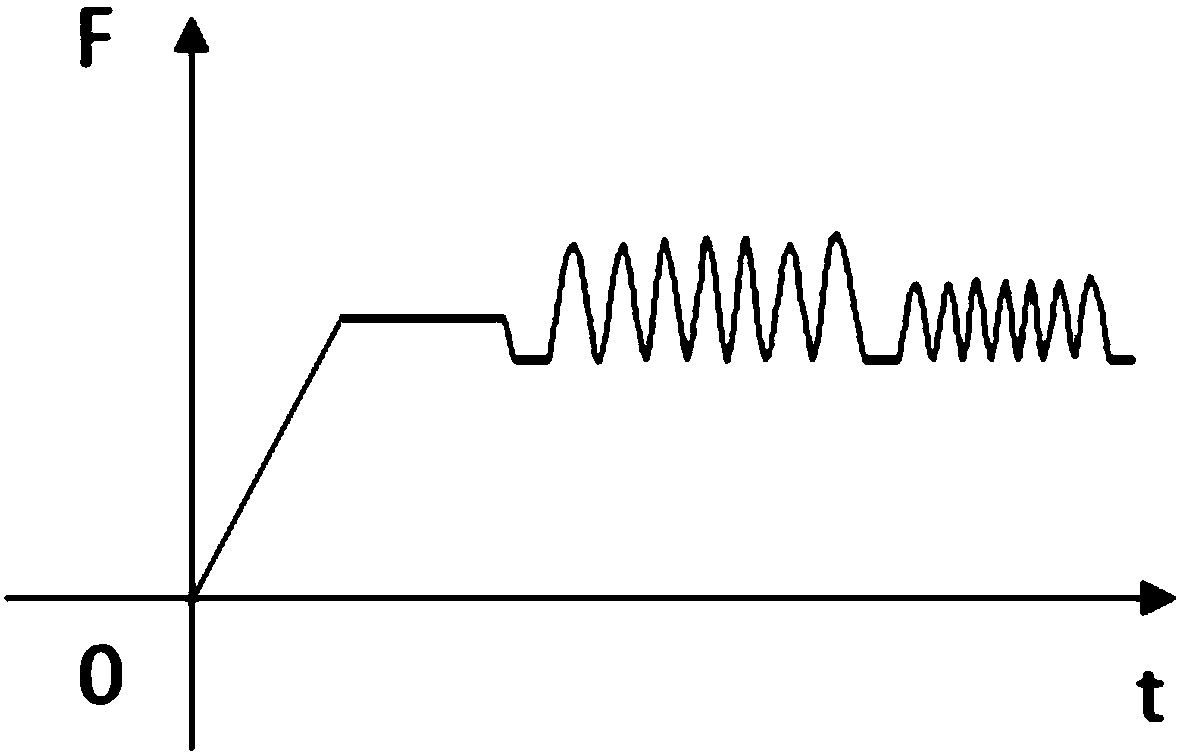

[0032] Constant, fatigue stress test apparatus, such as figure 1 As shown, it includes a workbench, a transparent frame is set on the workbench table 5, and a clamping part 6 for fixing the specimen is set on the frame, and the clamping part 6 is connected to the axial stress loading system. The axial stress loading system It includes a force sensor 6, a lead screw 7 and a servo motor 8 that are sequentially arranged in the worktable. The force sensor 6 is located between the clamping portion 6 and the lead screw 7 to detect the magnitude of the mechanical load loaded. One end of the lead screw 7 connects the force The other end of the sensor 6 and the lead screw 7 is connected to the output end of the servo motor 8 ; the input end of the servo motor 8 is connected to the control system that controls the operation of the servo motor 8 .

[0033]The control system includes a control cabinet 10, and a digital controller 11 is arranged in the control cabinet 10. The digital contr...

Embodiment 2

[0042] In order to facilitate further understanding of the environment-constant, fatigue stress synergistic test method of the present invention, the environment-stress synergy test is described in detail by taking a dumbbell-shaped tensile specimen as an example.

[0043] The sample is a dumbbell-shaped tensile sample with a straight section of 20 mm × 1.5 mm, and the sample is vertically fixed between the upper and lower clamping parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com