Recovery method of waste lead-acid storage battery

A lead-acid battery, repair method technology, applied in the direction of secondary battery repair/maintenance, secondary battery, secondary battery charging/discharging, etc. Efficiency and other issues, to achieve the effect of stable and good performance, increased utilization, and improved charging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

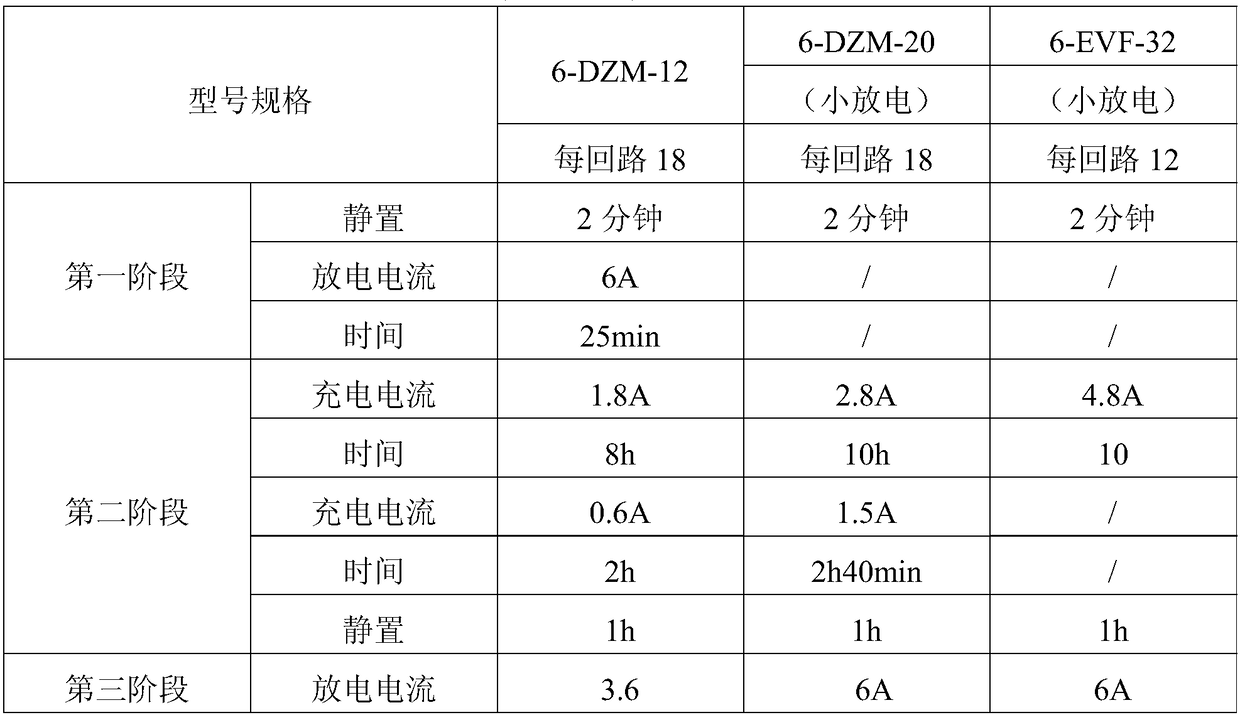

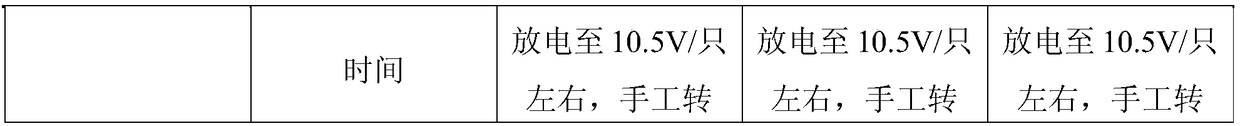

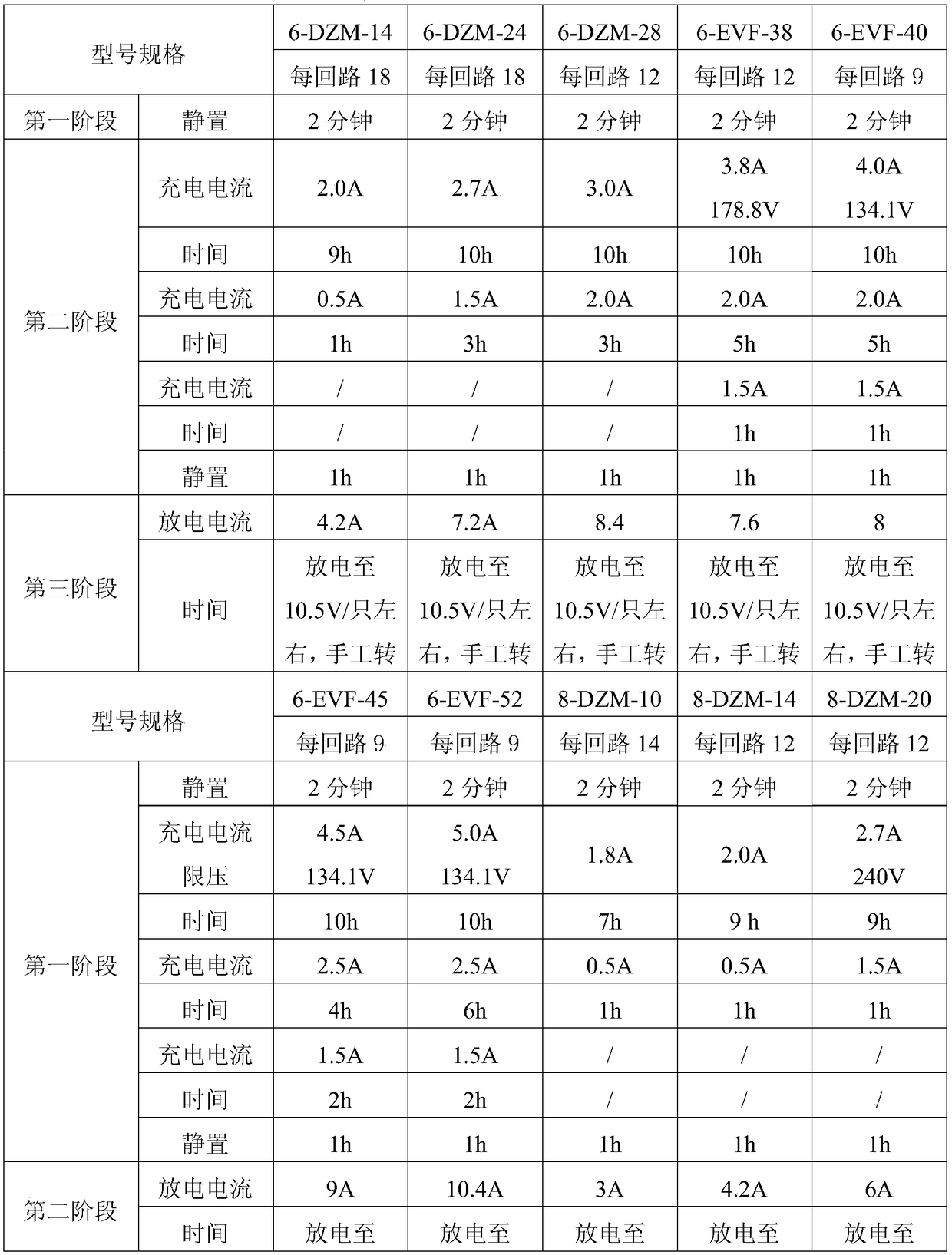

[0031] 1. Different types of small discharge repair methods for electric vehicle lead-acid batteries, including:

[0032] 1) Preparatory work: Put the batteries returned from the market in place, and select a small discharge repair instrument (current is 0-2A, voltage is 0-15V);

[0033] 2) Connect the battery and the small discharge repair instrument, each single battery and a single small discharge repair instrument form a circuit, start discharging (the current slowly changes from 2A to 0A, and the voltage 12-14V gradually decreases to 0V), when discharging The signal light is on, wait for the signal light to go out, and the discharge ends;

[0034] 3) After the discharge is over, check the open circuit voltage of a single battery. If the open circuit voltage is ≥ 10V, return to step 2), otherwise, proceed to the next step of repair;

[0035] 4) Put the battery on the shelf after standing for two hours, connect it to the bus-type charging and discharging equipment, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com