Slipper type 3D printer with parallel connecting rods and movable platform

A 3D printer, slider-type technology, applied in processing platforms/substrates, 3D object support structures, additive manufacturing, etc., can solve problems affecting printing quality, wire drawing, and high surface roughness of printed parts, avoiding printing failures, reducing The effect of drawing phenomenon and improving printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

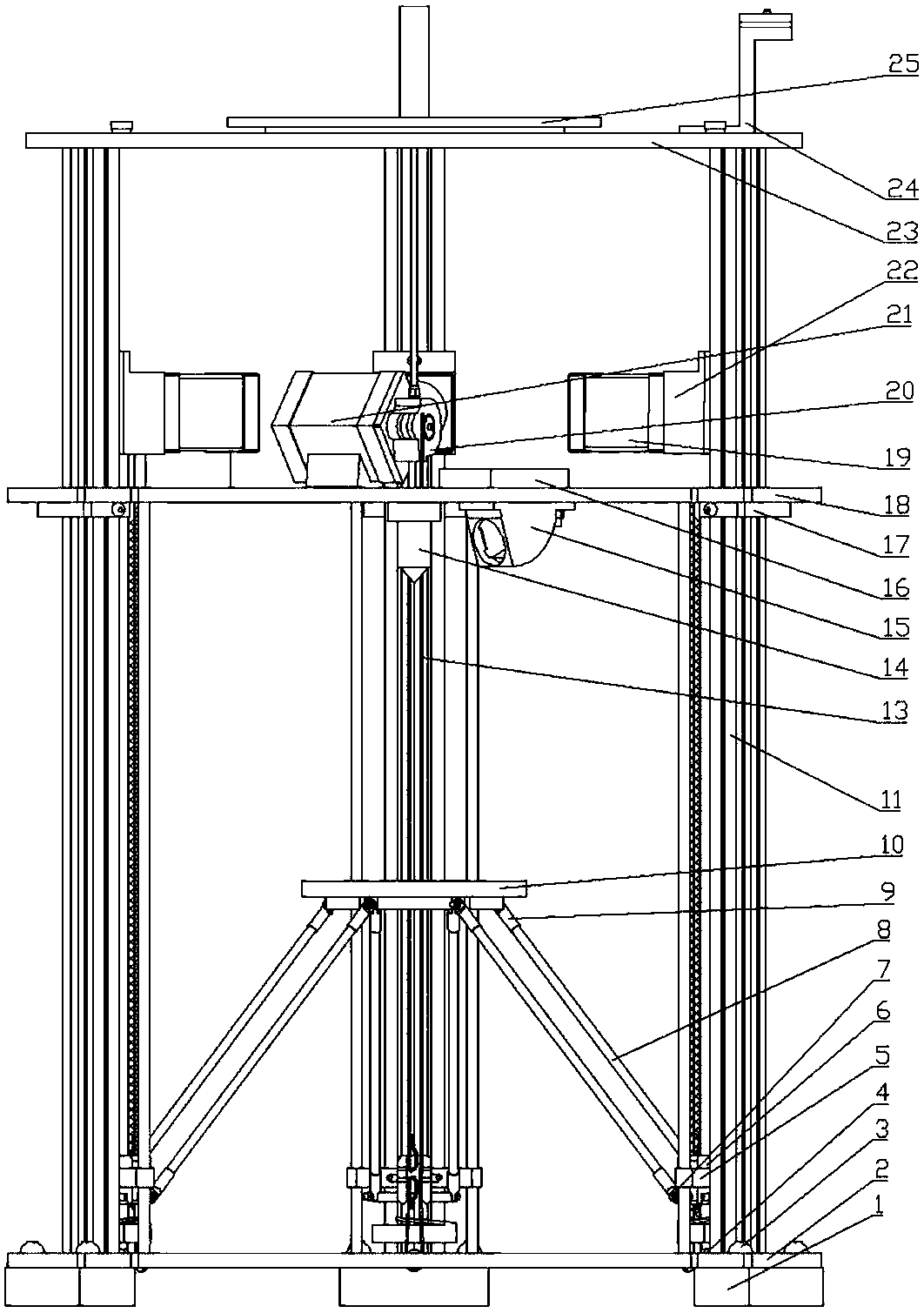

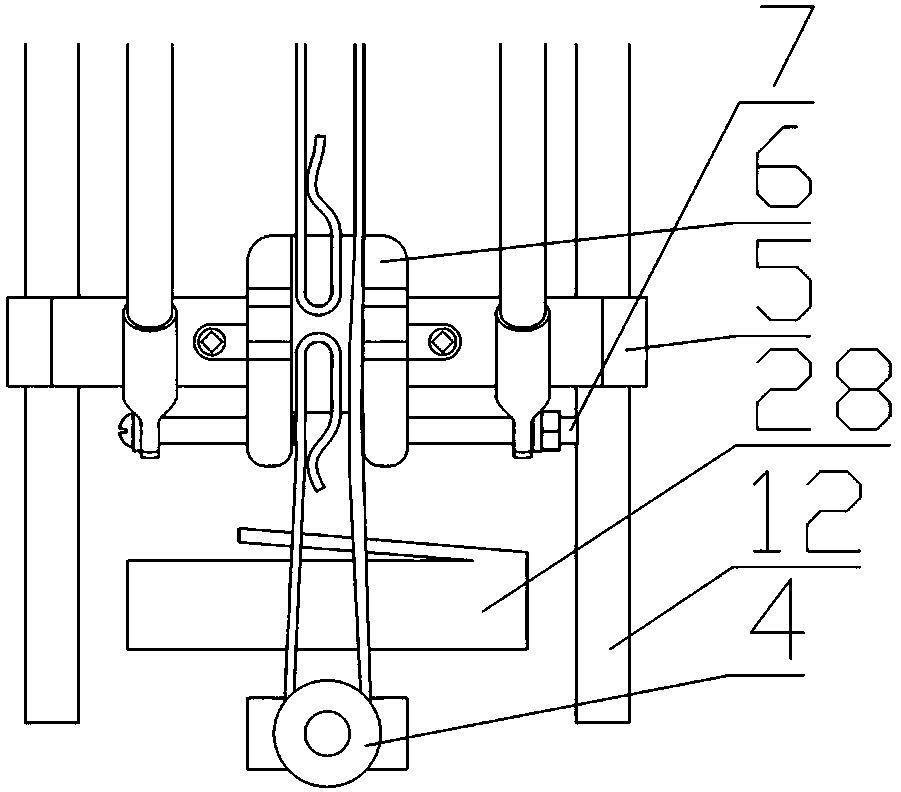

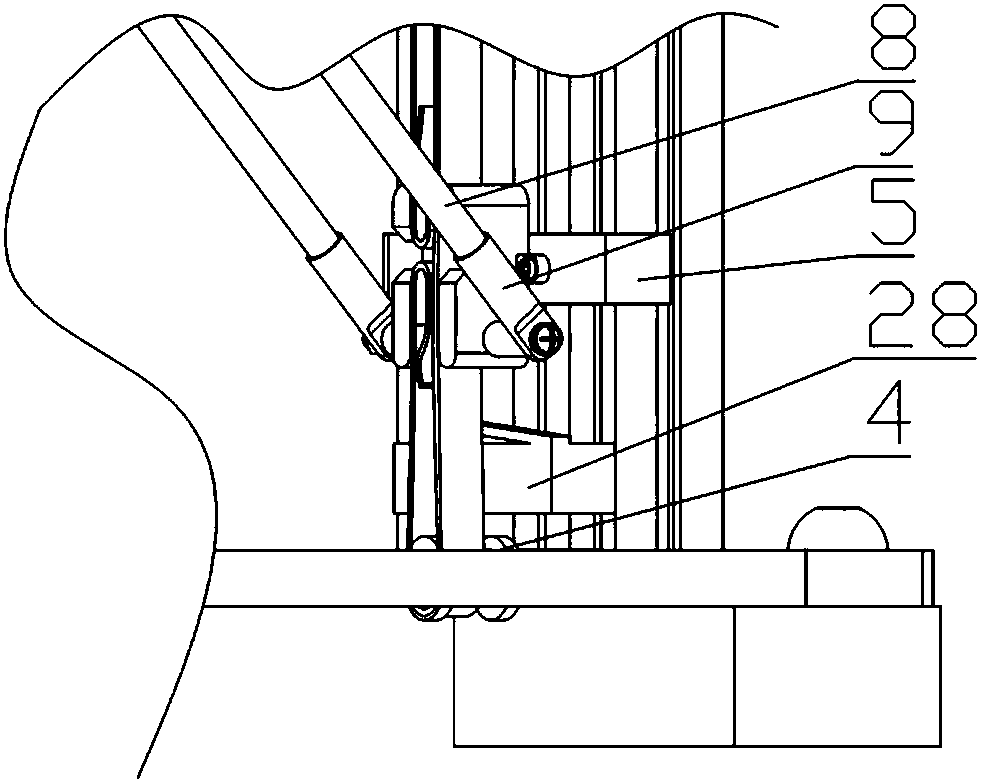

[0028] Such as figure 1 and figure 2 As shown, in this embodiment, a movable 3D printer with a parallel-link slider type platform is mainly composed of a double-layer cylindrical frame, a nozzle 14, a platform movement mechanism and a printing platform 10;

[0029] The frame is mainly composed of a base plate 2, a bracket 11, a nozzle support plate 18 and a top plate 23; wherein, the base plate 2 is located at the bottom of the frame, and three bases 1 are installed at the bottom of the base plate 2 as supports; there are six brackets 11, each Two groups are divided into three groups, evenly arranged on the base plate 2, and the lower end of the bracket 11 is inserted into the preset slot on the base plate 2, the middle part of the bracket 11 passes through the slot on the nozzle support plate 18, and the nozzle support plate 18 passes through it. The nozzle support plate fixing seat 17 fixedly installed below limits it on the bracket 11, and the upper part of the bracket 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com