Automatic exhaust device for transformer gas relay

An automatic exhaust, relay technology, applied in electrical components, circuits, electrical switches, etc., can solve problems such as low efficiency, transformer misdetection, shaking, etc., to achieve the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Further detailed explanation through specific implementation mode below:

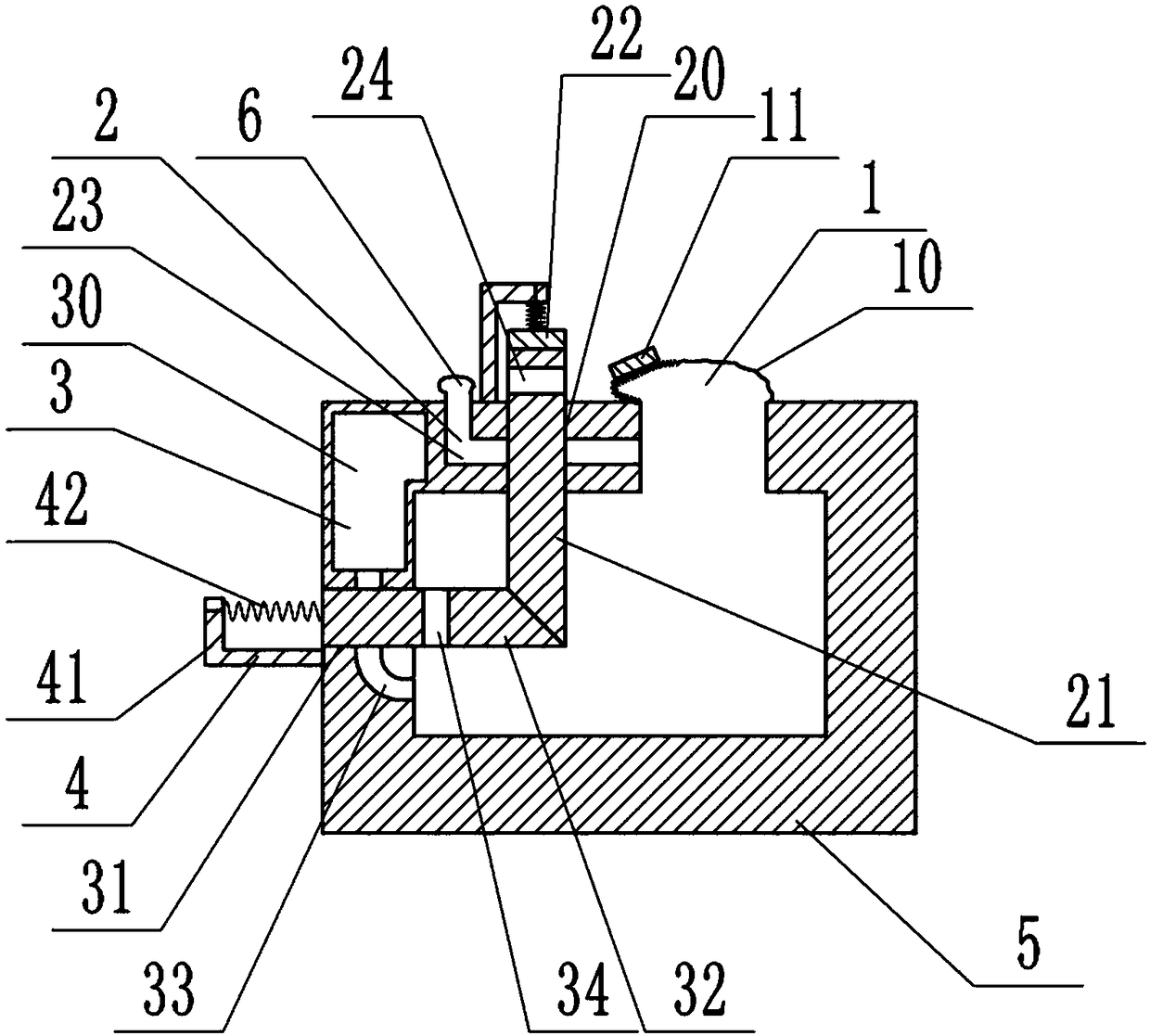

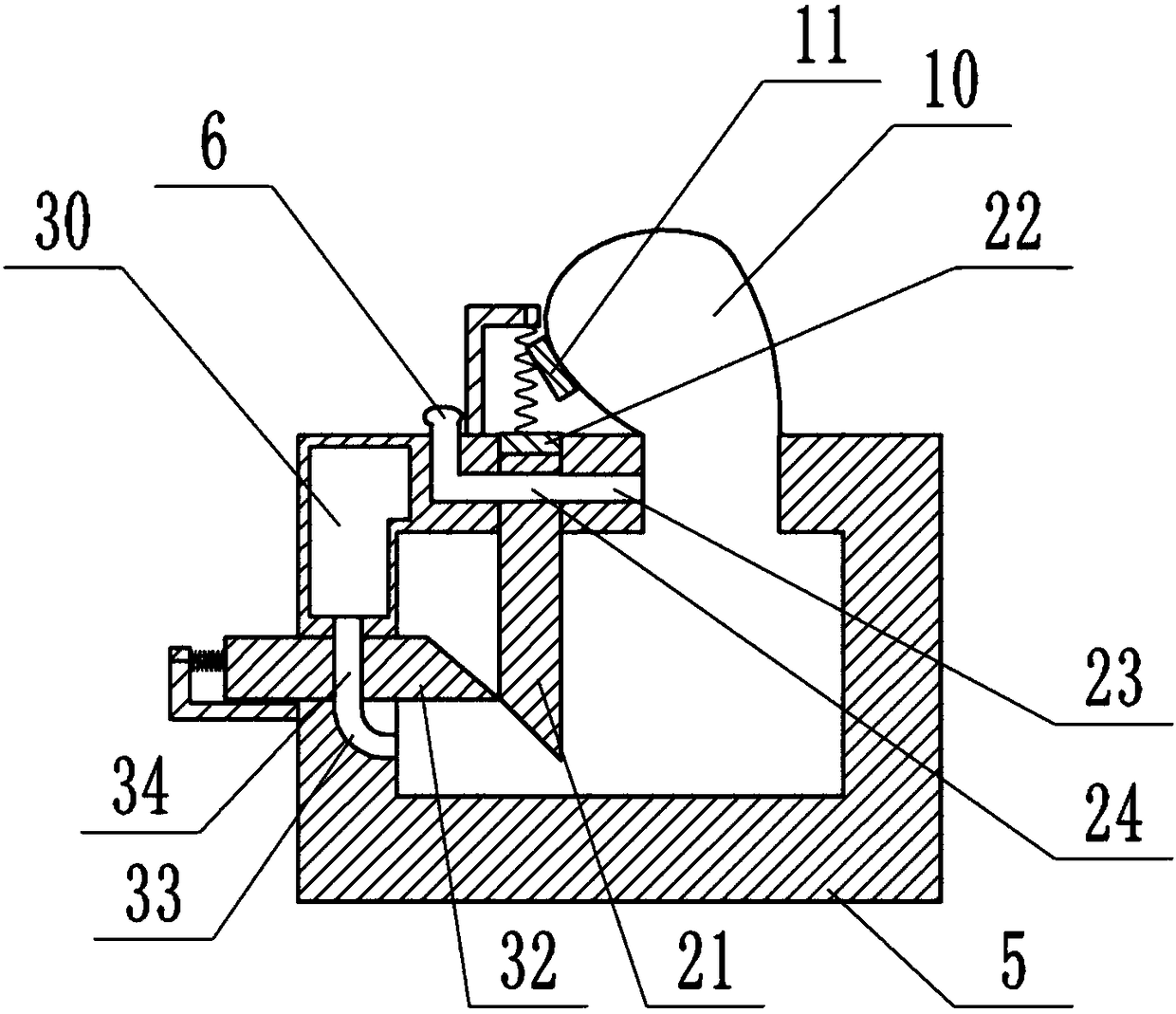

[0037] The reference signs in the drawings of the description include: gas collection mechanism 1, special-shaped airbag 10, magnet 11, exhaust mechanism 2, first through hole 20, first slider 21, magnet block 22, exhaust pipe 23, connecting hole 24. Oil supply mechanism 3, oil storage chamber 30, second through hole 31, second slider 32, oil supply pipeline 33, connection hole 34, reset mechanism 4, fixed frame 41, torsion spring 42, gas relay 5, Gas collection device 6.

[0038] Such as figure 1 and figure 2 As shown, the automatic exhaust device of transformer gas relay 5 of the present invention includes:

[0039] Gas collection mechanism 1, such as figure 1 As shown, an opening is provided at the upper end of the gas relay 5 biased to the right, and the opening on the top of the gas relay 5 is connected with a special-shaped air bag 10 by glue, and the special-shaped air bag 10 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com